The Role of AI in Enhancing Operational Efficiency and Reducing Costs

AI in Supply Chain Management for Swiss Companies: Revolutionizing Operations

AI in supply chain management for Swiss companies is rapidly transforming how businesses handle logistics, inventory, and demand forecasting. By leveraging artificial intelligence, Swiss companies can streamline their supply chains, allowing them to operate with greater precision and efficiency. AI-powered tools, such as machine learning algorithms and predictive analytics, help businesses anticipate demand fluctuations, manage stock levels, and optimize routes for transportation, leading to significant operational improvements.

One of the key benefits of integrating AI into supply chain management is the ability to make real-time decisions. AI-driven systems can process vast amounts of data from various sources, such as customer orders, weather conditions, and supplier information, to make informed decisions that adjust supply chain strategies dynamically. This level of responsiveness allows Swiss companies to avoid costly delays, reduce inventory waste, and respond more quickly to market changes.

Moreover, the use of AI in supply chains has led to improved collaboration across different departments and stakeholders. By providing a centralized platform where data is shared transparently, AI helps break down silos within organizations. This results in better communication between procurement, manufacturing, and logistics teams, ensuring that all parts of the supply chain are aligned with business goals. Overall, AI is not just optimizing processes but is also enabling Swiss companies to be more agile and responsive in an increasingly competitive market.

Cost Reduction through AI in Swiss Supply Chain Management

Swiss companies are finding that AI-driven supply chain management is a key driver of cost reduction. Through automation and improved decision-making, businesses can reduce expenses across various areas of their operations. One significant way AI helps reduce costs is by optimizing inventory management. By accurately predicting demand and automating stock replenishment processes, AI minimizes the risk of overstocking or understocking, which in turn reduces storage and inventory holding costs.

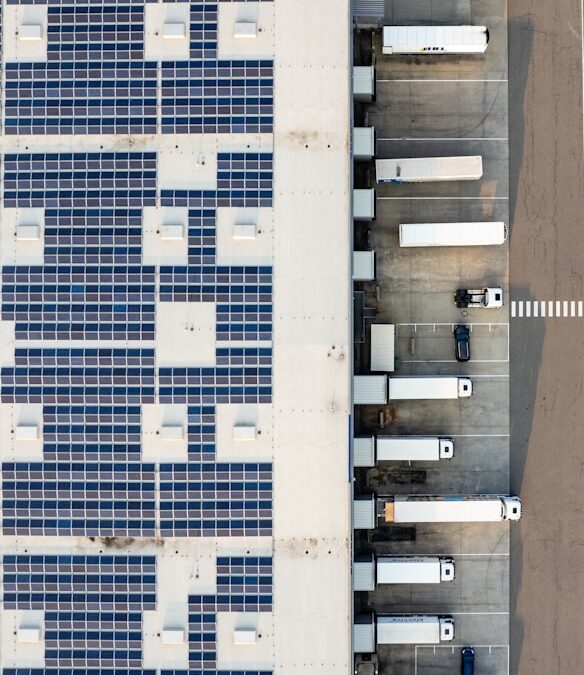

Transportation is another area where AI is contributing to cost savings. AI can analyze multiple factors, such as traffic patterns, fuel prices, and route efficiency, to determine the most cost-effective delivery routes. This not only reduces transportation costs but also lowers fuel consumption, contributing to more sustainable operations. By implementing AI-driven route optimization, Swiss companies are seeing faster delivery times and a reduction in logistics expenses.

In addition, AI helps Swiss companies identify inefficiencies in their supply chain processes. Machine learning models can highlight bottlenecks or unnecessary steps in production and logistics workflows, enabling businesses to streamline operations. This leads to reduced operational costs and improved profitability. As Swiss companies continue to adopt AI in their supply chains, they are gaining a competitive advantage through cost-effective and efficient operations.

Enhancing Operational Efficiency with AI in Supply Chain Management

The integration of AI into supply chain management is not only driving cost reduction but also significantly enhancing operational efficiency for Swiss companies. By automating routine tasks such as order processing, inventory tracking, and demand forecasting, AI allows businesses to reduce manual labor and focus on more strategic activities. This increases overall productivity and ensures that human resources are allocated to higher-value tasks.

AI also enhances supply chain visibility, giving Swiss companies a comprehensive view of their operations. With AI-powered dashboards and analytics tools, businesses can monitor every aspect of their supply chains in real time. This level of transparency allows companies to identify potential issues before they escalate, such as supplier delays or production slowdowns, and take proactive measures to mitigate risks.

Furthermore, AI-driven supply chain management enables Swiss companies to respond quickly to changing market conditions. By leveraging predictive analytics, businesses can forecast demand more accurately and adjust their production schedules accordingly. This flexibility allows companies to reduce lead times, improve customer satisfaction, and maintain optimal stock levels, ultimately boosting operational efficiency.

Improving Supply Chain Resilience with AI for Swiss Companies

In an increasingly volatile global market, supply chain resilience has become a critical factor for success. AI in supply chain management helps Swiss companies build more resilient supply chains by enabling real-time risk assessment and scenario planning. With AI, businesses can simulate various supply chain disruptions, such as supplier shortages or geopolitical issues, and develop contingency plans to address potential challenges.

AI also helps companies diversify their supplier networks by identifying alternative suppliers based on real-time data analysis. This reduces the risk of reliance on a single supplier and ensures that businesses can continue to operate even if one supplier faces disruptions. By using AI to monitor supplier performance and reliability, Swiss companies can make more informed decisions about which suppliers to engage with, further enhancing supply chain resilience.

Additionally, AI enables companies to optimize their inventory levels in response to changing demand patterns. By analyzing historical data and market trends, AI can predict potential fluctuations in demand and suggest adjustments to inventory levels accordingly. This ensures that Swiss companies are well-prepared to meet customer demands, even during unexpected market shifts, without holding excessive inventory that ties up capital.

The Future of AI in Supply Chain Management for Swiss Companies

As AI technology continues to evolve, its impact on supply chain management for Swiss companies is expected to grow even further. Emerging technologies such as AI-powered robotics, blockchain integration, and advanced predictive analytics will provide companies with even more sophisticated tools to manage their supply chains. Swiss businesses that continue to embrace AI will be well-positioned to lead in operational efficiency and innovation.

One promising area of development is the use of AI-powered robotics in warehouse management. Automated robots, driven by AI algorithms, are already being used to pick and pack items, reducing the need for manual labor and increasing throughput. This trend is likely to accelerate, with more Swiss companies adopting robotics to further streamline their supply chain operations.

Blockchain integration with AI also holds significant potential for enhancing supply chain transparency and security. By combining the immutable nature of blockchain with AI’s data processing capabilities, companies can ensure the authenticity of transactions and improve traceability across the supply chain. This will help Swiss companies maintain compliance with regulatory requirements and build greater trust with their customers and partners.

In conclusion, AI in supply chain management for Swiss companies is driving significant advancements in cost reduction, operational efficiency, and resilience. By embracing AI technologies, Swiss businesses are staying ahead of the competition, optimizing their processes, and positioning themselves for long-term success in a rapidly changing global market.

—

#SwissSupplyChain #AIinSupplyChain #OperationalEfficiency #CostReduction #AIandLogistics #DigitalTransformation #SwissBusinessInnovation