Enhancing Operational Efficiency with IoT Technology

Preventing Unexpected Breakdowns with IoT-Enabled Sensors

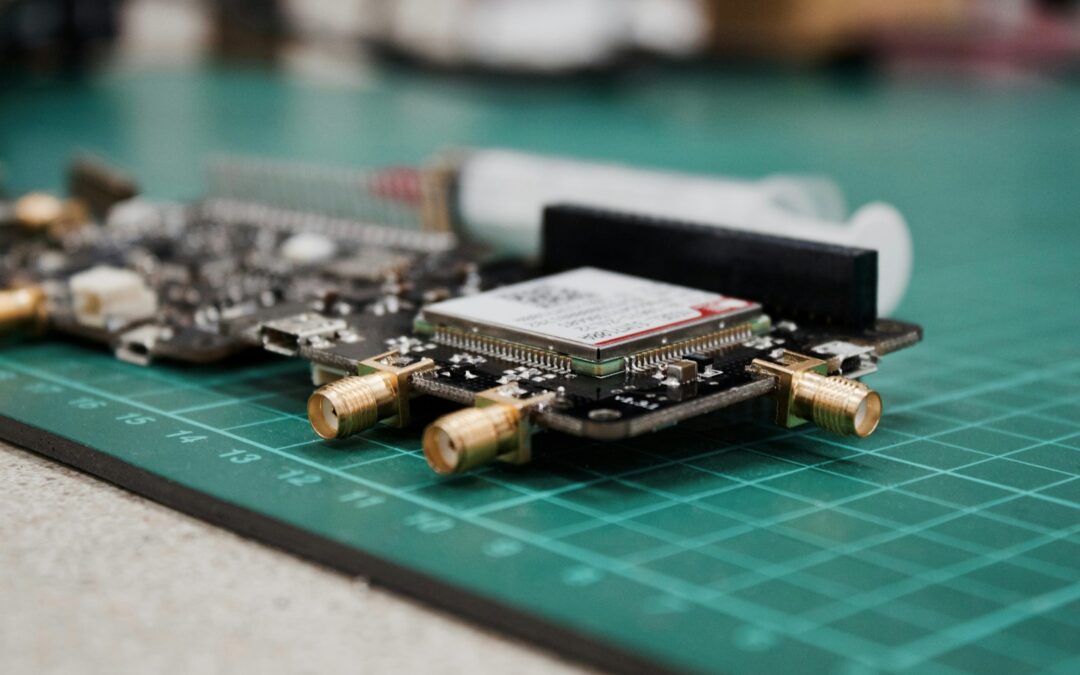

IoT-enabled sensors for manufacturing equipment are revolutionizing the industrial landscape by offering a proactive approach to maintenance that significantly reduces unexpected breakdowns and minimizes downtime. In the fast-paced world of manufacturing, where every minute of operation is critical, the ability to predict and prevent equipment failures can have a profound impact on productivity and cost savings. The integration of IoT technology with manufacturing equipment allows for real-time monitoring and analysis, enabling manufacturers to detect potential issues before they lead to costly disruptions.

IoT-enabled sensors work by continuously collecting data on various aspects of equipment performance, such as temperature, vibration, and pressure. This data is then analyzed using advanced algorithms to identify patterns that indicate wear and tear or other signs of impending failure. For instance, a sensor might detect an increase in vibration levels in a particular machine, which could suggest that a component is nearing the end of its life. By identifying this issue early, maintenance teams can schedule repairs or replacements during planned downtime, rather than being forced to halt production unexpectedly due to a sudden breakdown.

The implementation of IoT-enabled sensors not only enhances the reliability of manufacturing equipment but also extends its lifespan. By addressing minor issues before they escalate into major problems, manufacturers can avoid the need for frequent replacements and reduce the overall cost of ownership. Moreover, this approach aligns with the growing emphasis on sustainability in manufacturing, as it promotes the efficient use of resources and minimizes waste. In regions like Saudi Arabia and the UAE, where the manufacturing sector is rapidly expanding, the adoption of IoT technology is proving to be a key driver of industrial innovation and competitiveness.

Reducing Downtime with Predictive Maintenance Strategies

The integration of IoT-enabled sensors into manufacturing processes is a critical component of predictive maintenance strategies, which are designed to reduce downtime and optimize operational efficiency. Predictive maintenance leverages the data collected by IoT sensors to anticipate when equipment is likely to fail, allowing maintenance teams to intervene at the most opportune time. This approach differs from traditional reactive maintenance, where repairs are only carried out after a failure has occurred, often resulting in significant production losses and costly repairs.

In practice, predictive maintenance involves using IoT-enabled sensors to monitor key performance indicators (KPIs) that correlate with equipment health. For example, in a manufacturing plant in Riyadh, IoT sensors might track the temperature and pressure levels of a critical piece of machinery. If the data indicates that these parameters are approaching unsafe levels, the system can automatically alert the maintenance team to take preventive action. This not only prevents unexpected breakdowns but also ensures that equipment operates at peak efficiency, thereby maximizing productivity.

The benefits of predictive maintenance extend beyond simply reducing downtime. By optimizing the timing of maintenance activities, manufacturers can achieve more efficient use of their resources, including labor and spare parts. This can lead to significant cost savings, as maintenance is performed only when necessary, rather than on a fixed schedule that may result in unnecessary work. Additionally, the data generated by IoT-enabled sensors provides valuable insights into the performance of equipment over time, enabling manufacturers to make informed decisions about process improvements and equipment upgrades.

Case Studies: IoT-Enabled Predictive Maintenance in Action

The effectiveness of IoT-enabled sensors for manufacturing equipment is well-documented through various case studies across different industries. One notable example is a large automotive manufacturing plant in Dubai, where IoT technology was integrated into the assembly line to monitor critical machinery. Before the adoption of IoT sensors, the plant experienced frequent and costly downtimes due to unexpected equipment failures. However, after implementing IoT-enabled predictive maintenance, the plant reported a significant reduction in unplanned downtime, resulting in increased production capacity and lower maintenance costs.

Another example can be found in the food processing industry in Saudi Arabia, where IoT-enabled sensors have been used to monitor refrigeration units that are essential for preserving the quality of perishable products. By continuously tracking the temperature and operational status of these units, the system can detect early signs of malfunction, such as temperature fluctuations or compressor issues. This allows the maintenance team to address the problem before it leads to product spoilage, ensuring that the supply chain remains uninterrupted and that consumers receive high-quality products.

In the oil and gas sector, which is a major industry in the UAE, IoT-enabled sensors are being used to monitor the health of critical infrastructure, such as pipelines and drilling rigs. These sensors provide real-time data on parameters such as pressure, flow rate, and corrosion levels, enabling operators to detect and address potential issues before they escalate into costly failures. The adoption of IoT technology in this sector not only enhances operational efficiency but also improves safety by reducing the risk of accidents caused by equipment failure.

The Future of IoT in Manufacturing: Challenges and Opportunities

Overcoming Challenges in IoT Implementation

While the benefits of IoT-enabled sensors in manufacturing are clear, their implementation is not without challenges. One of the primary concerns is the integration of IoT technology with existing manufacturing systems, which may require significant investment in infrastructure and training. Additionally, the sheer volume of data generated by IoT sensors can be overwhelming, necessitating the development of advanced data analytics tools and platforms to process and interpret this information effectively. Manufacturers must also address concerns related to data security and privacy, as the increased connectivity of IoT devices presents potential vulnerabilities to cyber threats.

Despite these challenges, the adoption of IoT technology in manufacturing is expected to continue growing, driven by the need for greater efficiency and competitiveness. Governments in the Middle East, including Saudi Arabia and the UAE, are actively promoting the digital transformation of their manufacturing sectors through initiatives such as Saudi Vision 2030 and the UAE’s Fourth Industrial Revolution strategy. These initiatives emphasize the importance of IoT technology in achieving sustainable industrial growth and are likely to spur further investment in IoT-enabled solutions.

As manufacturers increasingly embrace IoT technology, they will need to develop strategies to overcome the challenges associated with its implementation. This may involve partnering with technology providers who can offer expertise in IoT integration and data analytics or investing in workforce training programs to equip employees with the necessary skills to manage and operate IoT systems. By addressing these challenges proactively, manufacturers can fully realize the benefits of IoT-enabled sensors and maintain a competitive edge in the global market.

The Strategic Advantage of IoT-Enabled Manufacturing

The strategic advantage of implementing IoT-enabled sensors for manufacturing equipment lies in the ability to create a more resilient and adaptive production environment. As global markets become increasingly competitive, manufacturers must find ways to differentiate themselves through operational excellence and innovation. IoT technology provides the tools to achieve this by enabling manufacturers to optimize their processes, reduce costs, and improve product quality.

Moreover, IoT-enabled manufacturing aligns with broader industry trends, such as the shift towards smart factories and Industry 4.0. By integrating IoT technology into their operations, manufacturers can create a fully connected and automated production environment where machines, systems, and people work together seamlessly. This not only enhances efficiency but also enables manufacturers to respond more quickly to changing market demands and customer needs.

In conclusion, the integration of IoT-enabled sensors with manufacturing equipment offers a powerful solution for preventing unexpected breakdowns and reducing downtime. As demonstrated by the success stories from various industries, IoT technology is transforming the manufacturing landscape by providing real-time insights and enabling predictive maintenance strategies. While challenges remain, the strategic advantages of IoT-enabled manufacturing are clear, and companies that invest in this technology today are likely to lead the industry in the years to come.

#IoT #Manufacturing #PredictiveMaintenance #IndustrialIoT #SmartManufacturing #EquipmentReliability #OperationalEfficiency