Navigating the Challenges of Predictive Maintenance with Machine Learning

Data Quality and Integration: The First Hurdle

Adopting predictive maintenance with machine learning offers significant potential for enhancing operational efficiency and reducing downtime in manufacturing. However, companies in Saudi Arabia, the UAE, Riyadh, and Dubai often encounter challenges that can impede the successful implementation of this advanced technology. One of the primary challenges is ensuring high-quality data and seamless integration of machine learning models into existing systems. Predictive maintenance relies heavily on accurate, comprehensive, and timely data to function effectively. Without robust data collection and management practices, the models may produce unreliable predictions, leading to inefficiencies rather than improvements.

Data integration poses another significant challenge. Many companies operate with legacy systems that were not designed to work with modern machine learning technologies. Integrating these systems with new AI-driven solutions can be complex and resource-intensive, requiring both technical expertise and significant investment. To address these challenges, companies must prioritize data quality from the outset, implementing advanced data management tools and techniques. Additionally, collaborating with experienced IT consultants and data scientists can facilitate smoother integration, ensuring that machine learning models are properly aligned with existing infrastructure.

Skill Gaps and Workforce Adaptation

Another major challenge that companies face when adopting predictive maintenance with machine learning is the skill gap within their workforce. Machine learning technologies require specialized knowledge that many existing employees may not possess. This gap can hinder the successful deployment and utilization of predictive maintenance solutions, as employees may struggle to understand and manage these advanced systems. In regions like Saudi Arabia and the UAE, where rapid technological advancements are common, ensuring that the workforce is adequately trained to handle new technologies is essential for business success.

To overcome this challenge, companies should invest in comprehensive training programs aimed at upskilling their workforce. Executive coaching services and specialized training sessions can help leaders and employees alike gain the necessary skills to leverage machine learning effectively. Additionally, fostering a culture of continuous learning and innovation within the organization can encourage employees to embrace new technologies and adapt to changing industry demands. By addressing the skill gap, businesses can empower their teams to maximize the benefits of predictive maintenance and drive long-term success.

Managing Change and Securing Stakeholder Buy-In

The implementation of predictive maintenance with machine learning often requires significant changes to existing business processes and workflows. These changes can be met with resistance from employees and stakeholders who are accustomed to traditional maintenance practices. Effective change management is therefore crucial to overcoming this challenge. Leaders must communicate the benefits of predictive maintenance clearly and persuasively, highlighting how it can improve operational efficiency, reduce costs, and enhance overall business performance.

Securing stakeholder buy-in is equally important. This involves not only convincing upper management of the strategic value of predictive maintenance but also ensuring that all levels of the organization are on board with the transition. In the competitive business environments of Riyadh and Dubai, where innovation and efficiency are key drivers of success, securing broad-based support for new initiatives is essential. Companies can achieve this by involving stakeholders early in the planning process, addressing their concerns, and demonstrating the tangible benefits of the technology through pilot programs and case studies.

Building a Strong Technological Foundation

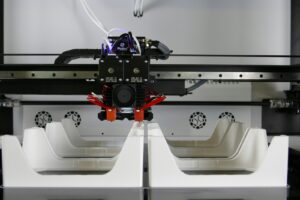

To effectively adopt predictive maintenance with machine learning, companies must build a strong technological foundation that supports data integration, model deployment, and system scalability. This begins with investing in advanced data analytics platforms and IoT (Internet of Things) devices that can capture and process vast amounts of data in real time. Additionally, businesses should focus on creating a flexible IT infrastructure that can accommodate future technological advancements without requiring significant overhauls.

In regions like Saudi Arabia and the UAE, where technological innovation is a priority, staying ahead of the curve is crucial. Companies should consider partnering with leading technology providers to ensure they have access to the latest tools and resources. By building a robust technological foundation, businesses can position themselves to fully leverage the benefits of predictive maintenance and maintain a competitive edge in their industry.

#PredictiveMaintenance #MachineLearning #AIInManufacturing #BusinessSuccess #SaudiArabiaTech #UAEInnovation #RiyadhBusiness #DubaiIndustry #ChangeManagement #LeadershipSkills #ManagementConsulting