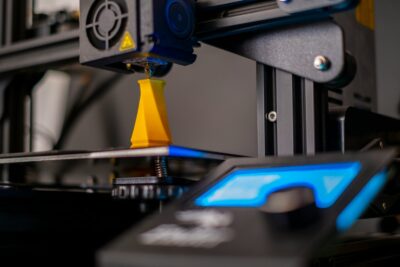

How 3D Printing is Transforming Automotive Manufacturing

Customization in the Automotive Industry through 3D Printing

The rise of 3D printing in the automotive industry has heralded a new era of customization and efficiency, offering unprecedented opportunities for innovation. In Saudi Arabia and the UAE, where the automotive market is rapidly expanding, 3D printing technology is playing a crucial role in meeting the increasing demand for customized automotive parts. By enabling the production of bespoke components tailored to individual specifications, 3D printing allows manufacturers to cater to unique customer preferences and requirements, enhancing customer satisfaction and brand loyalty.

The ability to produce customized parts quickly and cost-effectively is a game-changer for automotive manufacturers. Traditional manufacturing methods often involve lengthy processes and significant financial investments, especially when producing small batches of custom parts. In contrast, 3D printing significantly reduces lead times and costs, making it an attractive option for automakers in Riyadh and Dubai, who are looking to stay ahead of the competition. This technological advancement not only improves operational efficiency but also supports sustainable manufacturing practices by minimizing waste and optimizing the use of materials.

Moreover, the integration of 3D printing technology into the automotive supply chain enhances the agility and responsiveness of manufacturers. With the capacity to rapidly prototype and produce parts on-demand, companies can swiftly adapt to changing market conditions and customer needs. This flexibility is particularly beneficial in the context of executive coaching services and management consulting, where businesses seek to foster innovation and agility in their operations. By embracing 3D printing, automotive companies can drive continuous improvement and maintain a competitive edge in a dynamic market environment.

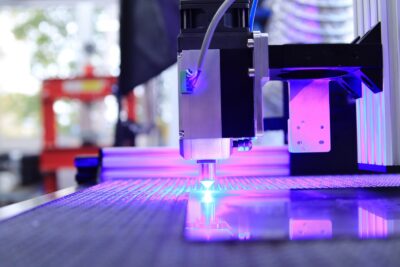

Efficiency Gains in Automotive Manufacturing with 3D Printing

Efficiency is a critical factor in the success of any manufacturing process, and 3D printing in the automotive industry offers significant advantages in this regard. In Saudi Arabia and the UAE, where the automotive sector is experiencing rapid growth, the need for efficient production methods is paramount. 3D printing streamlines the manufacturing process by reducing the number of steps required to produce complex parts. This reduction in complexity not only accelerates production timelines but also minimizes the potential for errors, resulting in higher-quality end products.

One of the key benefits of 3D printing is its ability to produce intricate and complex geometries that would be challenging or impossible to achieve with traditional manufacturing techniques. This capability is particularly valuable in the production of lightweight components, which are essential for improving vehicle fuel efficiency and performance. By leveraging 3D printing, automotive manufacturers can create parts that are both lightweight and strong, contributing to the development of more energy-efficient and environmentally friendly vehicles. This aligns with the broader goals of sustainability and innovation that are central to the visions of Saudi Arabia and the UAE.

Furthermore, 3D printing facilitates the creation of digital inventories, where parts can be stored in digital form and produced on-demand. This approach reduces the need for physical storage space and lowers inventory holding costs, leading to more efficient resource management. The digitalization of inventories also enables seamless integration with other advanced technologies such as Artificial Intelligence (AI) and Blockchain, further enhancing operational efficiency. For instance, AI can optimize production schedules and predict maintenance needs, while Blockchain can ensure the transparency and traceability of the supply chain.

Enhancing Business Success through 3D Printing and Executive Coaching

Incorporating 3D printing in the automotive industry not only transforms manufacturing processes but also offers strategic advantages for business success. In regions like Riyadh and Dubai, where technological innovation is highly valued, businesses that adopt 3D printing can position themselves as leaders in the market. This technological edge can be further enhanced through executive coaching services, which help business leaders navigate the complexities of integrating new technologies into their operations.

Executive coaching provides valuable insights and strategies for leveraging 3D printing to achieve business objectives. By focusing on effective communication, leadership and management skills, and project management, executive coaches can guide automotive executives in making informed decisions that drive growth and innovation. This support is crucial in ensuring that the adoption of 3D printing technology translates into tangible benefits for the organization, including improved operational efficiency, enhanced product quality, and increased customer satisfaction.

Additionally, the adoption of 3D printing aligns with the broader trends of digital transformation and the Metaverse, which are reshaping the business landscape. In the automotive industry, these trends are driving the development of connected and intelligent vehicles that offer new levels of convenience and functionality. By integrating 3D printing with technologies like Generative Artificial Intelligence, automotive companies can accelerate the design and production of these advanced vehicles, staying ahead of the competition and meeting the evolving needs of customers.

The Future of the Automotive Industry with 3D Printing

As 3D printing continues to evolve, its impact on the automotive industry is expected to grow even further. In Saudi Arabia and the UAE, where the focus on innovation and sustainability is strong, 3D printing will play a pivotal role in shaping the future of automotive manufacturing. The technology’s ability to produce high-quality, customized parts quickly and efficiently makes it an indispensable tool for automakers looking to stay competitive in a rapidly changing market.

The integration of 3D printing with other advanced technologies such as AI and Blockchain will further enhance its potential. AI can be used to optimize the design and production processes, ensuring that parts are manufactured to the highest standards of quality and performance. Blockchain, on the other hand, can provide a secure and transparent way to track the entire production process, from the initial design to the final product. This level of transparency is particularly important in the automotive industry, where ensuring the quality and safety of parts is critical.

Moreover, the use of 3D printing in the automotive industry is not limited to the production of parts. It can also be used in the development of new materials that are stronger, lighter, and more sustainable than traditional materials. These new materials can help automakers meet the growing demand for more environmentally friendly vehicles, contributing to global efforts to reduce carbon emissions and combat climate change.

In conclusion, the adoption of 3D printing in the automotive industry offers numerous benefits, from increased customization and efficiency to enhanced business success and sustainability. In regions like Riyadh and Dubai, where innovation and technological advancement are highly valued, 3D printing is poised to revolutionize the automotive industry, driving growth and competitiveness. As the technology continues to evolve, its impact on the industry will only grow, making it an essential tool for automakers looking to stay ahead of the curve.

#3Dprinting #automotiveindustry #customization #SaudiArabia #UAE #executivecoaching #businesssuccess #managementconsulting #AI #Blockchain #Metaverse #GenerativeAI #leadership #projectmanagement