How Innovations in 3D Printing Can Elevate Your Product Development

In today’s dynamic business landscape, the pursuit of innovation and efficiency is a paramount objective for business executives, mid-level managers, and entrepreneurs. The quote, “Integrate 3D printing solutions for rapid prototyping,” encapsulates a transformative approach that can drive substantial change in product development. In this article, we will explore the significance of 3D printing, its role in change management, and how it empowers businesses to achieve rapid prototyping and, ultimately, success.

The Imperative of Rapid Prototyping

In an era characterized by fast-paced technological advancements and shifting consumer preferences, businesses face the challenge of bringing products to market swiftly and efficiently. Rapid prototyping addresses this challenge by offering several advantages:

Faster Time-to-Market: Accelerating the product development cycle ensures that businesses can seize opportunities and respond to market demands promptly.

Cost Savings: Identifying and rectifying design flaws early in the development process minimizes costly revisions later on.

Enhanced Innovation: Frequent prototyping encourages innovation and experimentation, fostering a culture of continuous improvement.

Reduced Risk: By thoroughly testing prototypes, businesses can identify and mitigate risks before mass production, reducing the potential for costly recalls or failures.

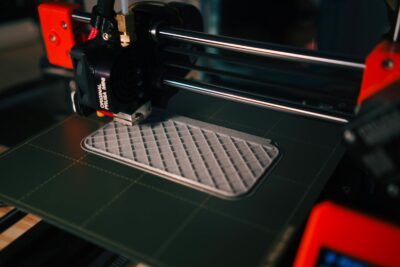

The Role of 3D Printing in Rapid Prototyping

3D printing, also known as additive manufacturing, has emerged as a game-changer in the field of rapid prototyping. Unlike traditional prototyping methods that are often time-consuming and costly, 3D printing offers several key benefits:

1. Speed and Agility

3D printing enables the rapid creation of physical prototypes. Design iterations can be produced in a matter of hours or days, allowing for swift adjustments and improvements.

2. Cost-Efficiency

Traditional manufacturing methods often involve expensive tooling and setup costs. 3D printing eliminates these expenses, making it an economical choice for prototypes.

3. Complex Geometries

3D printing can produce intricate and complex designs that are difficult or impossible to achieve with conventional manufacturing methods.

4. Customization

Businesses can create customized prototypes tailored to specific customer requirements, enhancing their ability to meet diverse market demands.

Change Management and 3D Printing Adoption

Implementing 3D printing solutions for rapid prototyping often requires a significant shift in the way businesses approach product development. Effective change management plays a critical role in the successful adoption of this technology:

1. Leadership Commitment

Leaders must champion the adoption of 3D printing and emphasize its importance in driving innovation and competitiveness.

2. Workforce Training

Employees need training to operate 3D printers and software effectively. Investing in workforce development is essential for a smooth transition.

3. Data Integration

Integrating 3D printing into existing design and production processes requires careful planning and data integration.

4. Collaboration and Cross-Functional Teams

Cross-functional teams should collaborate to ensure that 3D printing aligns with organizational goals and fosters innovation.

5. Measurement and Evaluation

KPIs and metrics should be established to measure the impact of 3D printing on product development, such as reduced development time or cost savings.

Case Study: Transforming Product Development with 3D Printing

To illustrate the transformative impact of 3D printing on rapid prototyping, let’s examine a real-world case study:

Company XYZ: Streamlining Product Development

Company XYZ, an aerospace manufacturer, faced challenges in developing complex components for their aircraft. Traditional prototyping methods were time-consuming and costly, delaying product launches.

Step 1: Adoption of 3D Printing

Recognizing the need for innovation, Company XYZ invested in 3D printing technology. They acquired state-of-the-art 3D printers and trained their engineering teams to use them effectively.

Step 2: Speed and Efficiency

With 3D printing in place, Company XYZ could produce intricate prototypes rapidly. This reduced the development cycle by 50%, allowing them to bring new components to market much faster.

Step 3: Cost Savings

The elimination of tooling and setup costs resulted in significant cost savings for Company XYZ. They could allocate resources more efficiently to other critical areas.

Results:

The impact of adopting 3D printing was substantial:

Faster product development and time-to-market.

A 30% reduction in prototyping costs.

Enhanced innovation, leading to the creation of cutting-edge components.

A competitive advantage in the aerospace industry.

Leadership and Management Skills in 3D Printing Adoption

Effective leadership and management skills are crucial in driving the adoption of 3D printing for rapid prototyping:

1. Visionary Leadership

Leaders must articulate a clear vision for the integration of 3D printing and communicate its strategic importance in the organization.

2. Change Management Expertise

Change management skills are vital for navigating the transition to 3D printing. Leaders should address resistance, provide support, and ensure alignment with organizational goals.

3. Technological Acumen

A strong understanding of 3D printing technology is essential for making informed decisions about equipment, software, and processes.

4. Collaboration and Innovation

Leaders should foster a culture of collaboration and innovation, encouraging teams to explore the full potential of 3D printing.

Conclusion

In conclusion, the quote “Integrate 3D printing solutions for rapid prototyping” underscores the transformative potential of 3D printing in product development. Rapid prototyping is not just a competitive advantage; it’s a necessity in today’s fast-paced business landscape.

By adopting 3D printing, businesses can achieve faster time-to-market, cost-efficiency, and the ability to create complex prototypes. However, successful adoption requires effective change management, leadership commitment, workforce training, and a strategic approach to integration.

Effective leadership and management skills are essential in driving the adoption of 3D printing technology. Leaders who champion innovation and guide their teams through the transition can position their organizations for success in a rapidly evolving marketplace.

#3DPrinting #RapidPrototyping #Innovation #ChangeManagement #LeadershipSkills #TechnologyIntegration #ProductDevelopment #BusinessSuccess