How 5G is Accelerating Industry 4.0 in Manufacturing

5G is poised to become a game-changer in the realm of industrial automation, ushering in a new era of intelligent manufacturing and smart factories. With its exceptional speed, low latency, and robust connectivity, 5G is empowering businesses to implement advanced automation systems that were previously unattainable. For industrial hubs like Saudi Arabia and the UAE, this transformation promises enhanced productivity, efficiency, and global competitiveness.

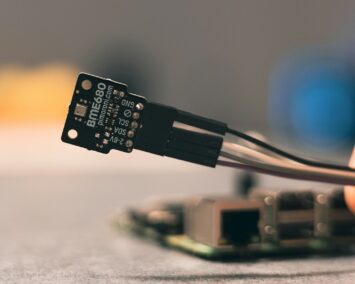

Unleashing the Potential of Industrial Internet of Things (IIoT)

5G networks are the backbone of the Industrial Internet of Things (IIoT), a network of interconnected devices and sensors that collect and exchange data in real time. The high bandwidth and low latency of 5G enable seamless communication between machines, robots, and other industrial equipment, facilitating the creation of truly smart factories. These interconnected systems can optimize production processes, monitor equipment health, predict maintenance needs, and enable proactive decision-making, ultimately leading to increased efficiency and reduced downtime.

Transforming Manufacturing with 5G Robotics

The integration of 5G and robotics is reshaping the manufacturing landscape. With 5G-enabled wireless connectivity, robots can now operate with greater flexibility and autonomy, untethered from physical cables. This allows for the deployment of collaborative robots (cobots) that can work alongside human workers, enhancing productivity and safety. Additionally, 5G’s real-time communication capabilities enable remote monitoring and control of robots, facilitating rapid response to issues and minimizing production disruptions.

Enabling Agile Manufacturing with 5G

5G is also instrumental in fostering agile manufacturing practices, where production lines can be quickly reconfigured to accommodate changing product demands or market trends. The flexibility and scalability of 5G networks allow for the seamless integration of new devices and sensors, enabling manufacturers to adapt their operations rapidly. This agility is crucial in today’s dynamic business environment, where the ability to respond to market shifts can determine success or failure.

Data-Driven Insights for Enhanced Decision-Making

5G enables the collection and analysis of massive amounts of data from industrial processes. This data can be leveraged to gain valuable insights into production performance, equipment efficiency, and resource utilization. By applying advanced analytics and machine learning algorithms to this data, manufacturers can identify areas for improvement, optimize processes, and make informed decisions to drive continuous improvement. This data-driven approach to manufacturing is essential for maintaining a competitive edge in the global market.

Creating a Safer and More Sustainable Manufacturing Environment

5G is not only about increasing productivity but also about creating a safer and more sustainable manufacturing environment. 5G-enabled safety systems can monitor worker movements, detect potential hazards, and trigger alerts or shutdowns to prevent accidents. Additionally, the use of 5G in industrial automation can lead to more efficient use of resources, such as energy and water, contributing to a greener and more sustainable manufacturing ecosystem. The focus on sustainability aligns perfectly with the broader environmental goals of countries like Saudi Arabia and the UAE, which are actively seeking to reduce their ecological footprint and promote sustainable development.

Embracing the 5G Revolution in Saudi Arabia and the UAE

Saudi Arabia and the UAE are at the forefront of embracing the 5G revolution in industrial automation. The governments of both countries are actively investing in 5G infrastructure and encouraging businesses to adopt this technology. The development of smart industrial zones and the promotion of digital transformation initiatives are creating a conducive environment for the growth of 5G-powered manufacturing. As companies in the region embrace this transformative technology, they are not only improving their operational efficiency but also contributing to the broader economic diversification and technological advancement goals of their respective countries.

#5G #IndustrialAutomation #Industry40 #SmartFactories #IIoT #Robotics #DigitalTransformation #Manufacturing