Transforming the Automotive Industry Through 3D Printing

The Evolution of Custom Parts Production

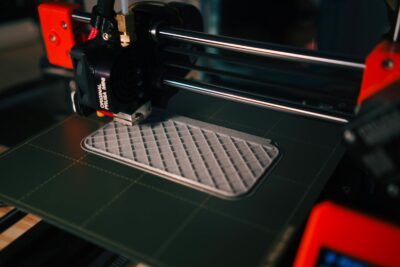

Rapid Custom Parts Production in Automotive is revolutionizing the way vehicles are designed, manufactured, and serviced, thanks to the unprecedented capabilities of 3D printing technology. In regions like Saudi Arabia and the UAE, where the automotive sector plays a vital role in economic growth, the adoption of 3D printing is reshaping industry standards. From Riyadh to Dubai, automotive companies are leveraging this technology to streamline production processes, reduce costs, and unlock new opportunities for innovation.

The traditional manufacturing methods used in the automotive industry often involve lengthy lead times and high costs, especially for custom parts production. However, with 3D printing, manufacturers can produce custom parts rapidly and cost-effectively, eliminating the need for expensive tooling and minimizing material waste. This agility enables automotive companies to respond swiftly to market demands, whether it’s for prototyping new vehicle models or providing aftermarket spare parts.

Moreover, the flexibility of 3D printing allows for the creation of highly complex and intricate parts that would be challenging or impossible to produce using traditional methods. This opens up new possibilities for vehicle design and performance optimization, driving innovation across the automotive value chain. By harnessing the power of 3D printing, automotive companies can differentiate themselves in the market and deliver superior products that meet the evolving needs of customers.

Strategic Implementation for Business Success

Successful integration of 3D printing into automotive manufacturing requires a strategic approach to change management and technology adoption. Executive coaching services can provide leadership teams with the guidance and support needed to navigate this transformational journey, ensuring that 3D printing initiatives align with broader organizational goals. Effective communication is also crucial for fostering collaboration and buy-in across all levels of the organization.

In addition to change management, investment in talent development and skills training is essential for maximizing the benefits of 3D printing. Leaders must possess the vision and expertise to drive innovation and champion the adoption of new technologies. Management consulting firms specializing in automotive manufacturing can offer valuable insights and support in developing tailored strategies for integrating 3D printing into existing operations.

Furthermore, collaboration with technology partners and suppliers is key to unlocking the full potential of 3D printing in the automotive industry. By establishing strategic partnerships and leveraging expertise in areas such as Artificial Intelligence and Blockchain, automotive companies can optimize production workflows, enhance quality control, and drive continuous improvement. By embracing innovation and investing in strategic partnerships, automotive manufacturers can position themselves for long-term success in a rapidly evolving market.

Conclusion: Shaping the Future of Automotive Manufacturing

In conclusion, the adoption of 3D printing for rapid custom parts production is reshaping the automotive industry and driving innovation at unprecedented speed. From Saudi Arabia to the UAE, automotive companies are embracing this technology to streamline production processes, reduce costs, and deliver superior products to customers. By leveraging the power of 3D printing and investing in strategic planning, leadership development, and technology partnerships, automotive manufacturers can stay ahead of the curve and shape the future of automotive manufacturing.

Embracing Technological Advancements for Growth

In summary, the automotive industry is at a pivotal moment of transformation, driven by advancements in 3D printing technology. By embracing innovation and investing in the capabilities needed to harness the full potential of 3D printing, automotive manufacturers can achieve greater agility, efficiency, and competitiveness in a rapidly evolving market. With the right strategy and leadership, companies in Saudi Arabia, the UAE, and beyond can unlock new opportunities for growth and success in the automotive sector.

Continued Innovation in Automotive Manufacturing

Looking ahead, the future of automotive manufacturing holds exciting possibilities as 3D printing technology continues to evolve and expand its capabilities. As advancements in materials science, software development, and process optimization drive innovation in additive manufacturing, automotive companies must remain agile and adaptable to stay ahead of the curve. By embracing a culture of continuous learning and innovation, companies can capitalize on the transformative potential of 3D printing and drive the industry forward.

—

#RapidCustomPartsProduction #AutomotiveIndustry #3DPrinting #SaudiArabia #UAE #Riyadh #Dubai #ChangeManagement #ExecutiveCoaching #EffectiveCommunication #BusinessSuccess #ManagementConsulting #ArtificialIntelligence #Blockchain #TheMetaverse #GenerativeAI #Leadership #ProjectManagement