Additive Manufacturing for Low-Volume Parts: A Game Changer in Production

Introduction to Additive Manufacturing

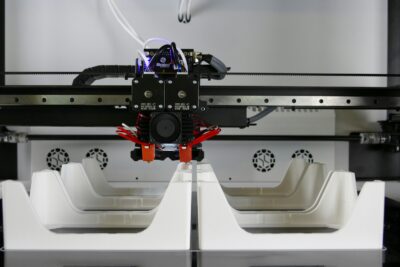

Additive manufacturing for low-volume parts is transforming the landscape of production in regions like Saudi Arabia and the UAE. With the advent of additive manufacturing, businesses are no longer constrained by the limitations of traditional manufacturing processes. This innovative technology, also known as 3D printing, allows for the rapid production of complex parts in low volumes, making it an ideal solution for industries requiring high precision and customization. In cities such as Riyadh and Dubai, where the focus is on rapid industrial development and technological advancement, additive manufacturing is proving to be a pivotal tool in achieving business success.

Additive manufacturing involves building parts layer by layer from a digital model, which contrasts sharply with subtractive manufacturing methods that remove material to create the final product. This method offers numerous advantages, including reduced material waste, increased design flexibility, and shorter production times. For mid-level managers and business executives, understanding the potential of additive manufacturing is crucial for staying competitive in today’s fast-paced market.

The Middle Eastern business environment, particularly in Saudi Arabia and the UAE, is embracing this technology to enhance production capabilities and meet the growing demand for customized products. As companies seek to optimize their operations and reduce costs, the strategic implementation of additive manufacturing can significantly contribute to achieving these goals.

Impact on Business Efficiency and Cost Reduction

The integration of additive manufacturing for low-volume parts into business operations has profound implications for efficiency and cost reduction. Traditional manufacturing methods often involve significant lead times and high costs, particularly for small production runs. Additive manufacturing mitigates these issues by enabling on-demand production, which is particularly beneficial for industries such as aerospace, healthcare, and automotive, where precision and customization are paramount.

In Riyadh and Dubai, where the focus on innovation and advanced manufacturing is high, businesses are leveraging additive manufacturing to streamline their production processes. This technology allows for the rapid prototyping and production of parts without the need for expensive molds or tooling. As a result, companies can respond more quickly to market demands and reduce their inventory costs by producing parts as needed rather than maintaining large stockpiles.

Moreover, additive manufacturing supports sustainable business practices by minimizing material waste and energy consumption. For businesses committed to environmental responsibility, this technology offers a path to greener manufacturing processes. By adopting additive manufacturing, companies in Saudi Arabia and the UAE can enhance their competitiveness and contribute to the region’s economic diversification goals.

Executive Coaching and Change Management in the Era of Additive Manufacturing

As businesses in Saudi Arabia and the UAE adopt additive manufacturing technologies, executive coaching and change management become critical components of successful implementation. The transition from traditional manufacturing methods to additive manufacturing requires a shift in mindset and a reevaluation of business processes. Executives and managers must be equipped with the knowledge and skills to lead their organizations through this transformation effectively.

Executive coaching services can provide leaders with the tools and strategies needed to navigate the complexities of implementing additive manufacturing. Coaches can help executives understand the technological aspects of additive manufacturing, as well as its implications for business operations and competitive strategy. In addition, they can assist in developing leadership skills that are essential for driving innovation and managing change.

Effective communication is also crucial in this context. Leaders must be able to articulate the benefits of additive manufacturing to their teams and stakeholders, fostering a culture of innovation and collaboration. Change management strategies, such as involving employees in the implementation process and providing continuous training, can help ensure a smooth transition and maximize the benefits of additive manufacturing.

The Role of Emerging Technologies in Enhancing Additive Manufacturing

Emerging technologies such as artificial intelligence (AI), blockchain, and the metaverse are playing a significant role in enhancing the capabilities of additive manufacturing. AI can optimize the design and production processes by analyzing vast amounts of data to identify patterns and improve efficiency. For example, AI algorithms can suggest design modifications that reduce material usage and production time, leading to cost savings and improved performance.

Blockchain technology offers a secure and transparent way to track the production and distribution of parts, ensuring quality control and reducing the risk of counterfeiting. This is particularly important in industries where the integrity of parts is critical, such as aerospace and healthcare. By integrating blockchain with additive manufacturing, businesses can create a robust supply chain that enhances trust and reliability.

The metaverse, a virtual reality space where users can interact with digital environments, offers new possibilities for collaboration and training in additive manufacturing. For instance, engineers and designers can use virtual reality to visualize and manipulate parts in 3D before they are produced, facilitating more effective design and troubleshooting. This immersive experience can also be used for training purposes, allowing employees to gain hands-on experience with additive manufacturing technologies in a controlled environment.

Leadership and Management Skills in the Additive Manufacturing Era

The successful implementation of additive manufacturing requires strong leadership and management skills. Leaders must be visionary, able to see the potential of new technologies and drive their adoption within their organizations. They must also be adept at managing change, guiding their teams through the transition and addressing any challenges that arise.

In Saudi Arabia and the UAE, where the push for innovation and technological advancement is strong, leaders in the manufacturing sector need to be particularly proactive. They must stay informed about the latest developments in additive manufacturing and related technologies, and be willing to invest in continuous learning and development. This will enable them to make informed decisions and capitalize on new opportunities.

Project management skills are also essential in this context. The implementation of additive manufacturing often involves complex projects that require careful planning and coordination. Effective project managers can ensure that these projects are completed on time and within budget, while also managing risks and ensuring quality standards are met. By developing strong project management capabilities, businesses can maximize the benefits of additive manufacturing and achieve their strategic objectives.

Conclusion: The Future of Additive Manufacturing in Business

The future of additive manufacturing in business looks promising, particularly in regions like Saudi Arabia and the UAE that are committed to innovation and technological advancement. As businesses continue to explore the potential of this technology, they will discover new ways to enhance production efficiency, reduce costs, and deliver customized products to their customers.

Additive manufacturing is not just a tool for production; it is a catalyst for change, driving businesses towards more sustainable and agile operations. By embracing this technology and investing in the necessary skills and resources, businesses can position themselves at the forefront of the manufacturing revolution.

In conclusion, the rapid production of low-volume parts enabled by additive manufacturing is transforming the manufacturing landscape. It offers significant advantages in terms of efficiency, cost reduction, and customization, making it an ideal solution for businesses in Saudi Arabia and the UAE. With strong leadership, effective change management, and the integration of emerging technologies, companies can fully realize the potential of additive manufacturing and achieve lasting business success.

#additivemanufacturing #3Dprinting #businesssuccess #SaudiArabia #UAE #Riyadh #Dubai #executivecoaching #changemanagement #artificialintelligence #blockchain #metaverse #leadership #managementskills #projectmanagement