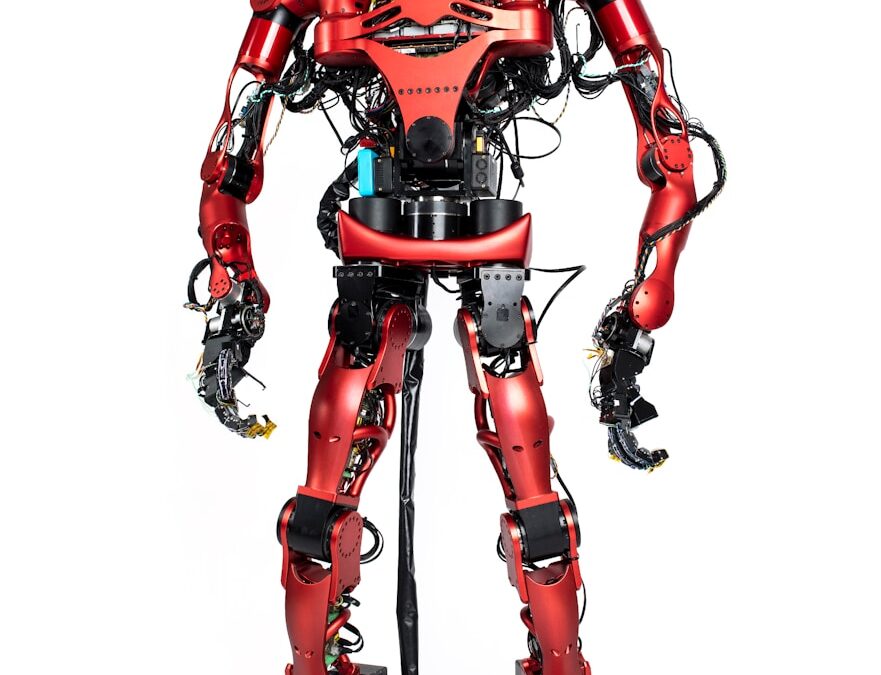

The Transformative Power of Advanced Robotics in Manufacturing

Enhancing Efficiency and Productivity

Advanced robotics in manufacturing is revolutionizing industries by enhancing efficiency and productivity. In regions like Saudi Arabia and the UAE, where innovation and technological advancement are key priorities, the integration of robotics into manufacturing processes is creating a significant impact. These robots, equipped with sophisticated sensors and AI capabilities, perform tasks with precision and speed, reducing human error and operational downtime. For instance, in Riyadh, advanced robotic systems are streamlining production lines in automotive and electronics industries, leading to increased output and higher quality products. Similarly, in Dubai, the use of robotics in manufacturing is driving economic growth by enabling companies to meet global standards and demands more effectively.

Driving Innovation through Automation

The role of automation in fostering innovation cannot be overstated. Advanced robotics enables the automation of repetitive and hazardous tasks, allowing human workers to focus on more strategic and creative endeavors. In Saudi Arabia and the UAE, where there is a strong emphasis on economic diversification and technological leadership, automation is critical. By adopting robotic solutions, businesses can enhance their research and development capabilities, leading to the creation of innovative products and services. For example, in Riyadh, the integration of robotics in manufacturing has led to the development of new materials and production techniques that are both cost-effective and sustainable. In Dubai, automation is paving the way for smart manufacturing, where interconnected systems and data analytics drive continuous improvement and innovation.

Ensuring Quality and Compliance

Maintaining high standards of quality and compliance is crucial in manufacturing. Advanced robotics plays a vital role in ensuring that products meet stringent regulatory requirements and industry standards. In Saudi Arabia and the UAE, where there is a strong focus on quality and international competitiveness, robotic systems are instrumental. These systems provide consistent and precise production, minimizing defects and ensuring that products are manufactured to exact specifications. In Riyadh, advanced robotics is used extensively in pharmaceuticals and aerospace manufacturing, where precision and reliability are paramount. Similarly, in Dubai, the adoption of robotics in manufacturing processes ensures that products meet global standards, enhancing the reputation and competitiveness of local industries on the international stage.

Change Management in Robotic Integration

Effective change management is essential for the successful integration of advanced robotics in manufacturing. Leaders in Saudi Arabia and the UAE must navigate the complexities of this technological transformation, ensuring that their organizations adapt seamlessly. This involves comprehensive planning, stakeholder engagement, and continuous training to address the challenges and opportunities presented by robotics. Executive coaching services can play a critical role in equipping leaders with the skills needed to manage this change effectively, fostering a culture of innovation and adaptability. In Riyadh and Dubai, where leadership development is a strategic priority, these services can significantly enhance the capacity of executives to lead their organizations through the transformative journey of robotic integration.

Leveraging AI and Blockchain in Robotics

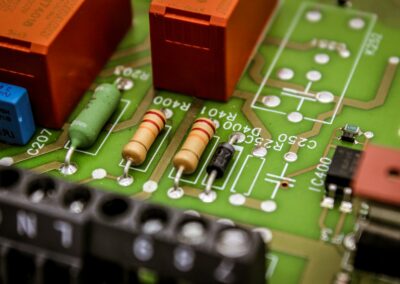

The integration of artificial intelligence (AI) and blockchain technology with advanced robotics is unlocking new possibilities for manufacturing. AI enables robots to learn and adapt to new tasks, improving their efficiency and capabilities. Blockchain, on the other hand, ensures the security and transparency of data, making it ideal for applications that require trust and traceability. In Saudi Arabia and the UAE, where digital transformation is a key strategic objective, combining AI and blockchain with robotics enhances operational efficiency and innovation. For instance, in Riyadh, AI-driven robots are used in logistics to optimize warehouse operations, while blockchain technology ensures the integrity of supply chain data. In Dubai, this combination is revolutionizing the manufacturing sector by providing secure, transparent, and efficient solutions.

Preparing for the Future of Work

The rise of advanced robotics is reshaping the future of work, necessitating new skills and competencies. Leaders in Saudi Arabia and the UAE must prepare their workforce for this shift, emphasizing continuous learning and development. Management consulting firms can provide valuable insights and strategies to help organizations navigate this transition. By fostering a culture of innovation and agility, companies can ensure that their employees are equipped to thrive in the age of robotics. In Riyadh and Dubai, where there is a strong emphasis on education and skill development, preparing for the future of work is a strategic priority. This involves investing in training programs, fostering collaboration between industry and academia, and promoting lifelong learning to build a resilient and adaptable workforce.

#AdvancedRobotics #ManufacturingProcesses #FutureofWork #SaudiArabia #UAE #Riyadh #Dubai #ChangeManagement #ExecutiveCoaching #BusinessSuccess #ManagementConsulting #AI #Blockchain #Metaverse #GenerativeAI #LeadershipSkills #ProjectManagement