Revolutionizing Industrial Efficiency with Edge Computing

The Role of Edge Computing in Industrial Robotics

Edge computing has emerged as a critical enabler for the autonomous Industrial Robotics Operations, offering numerous advantages that are transforming manufacturing and industrial processes. By processing data at or near the source of data generation, edge computing significantly reduces latency, allowing robots to make real-time decisions. This is especially important in industrial environments where split-second decisions are crucial for maintaining efficiency and safety. In the bustling industrial hubs of Riyadh and Dubai, the implementation of edge computing is driving unprecedented levels of operational efficiency and reliability.

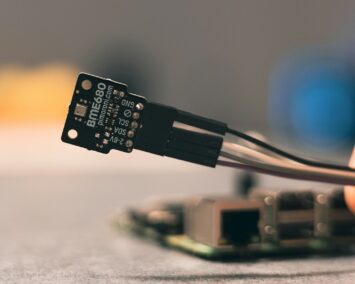

Industrial robots equipped with edge computing capabilities can operate autonomously, minimizing the need for constant human intervention. This autonomy is powered by the ability to quickly analyze and respond to data from various sensors and inputs. As a result, robots can perform complex tasks such as quality control, predictive maintenance, and adaptive manufacturing with minimal downtime. The edge computing infrastructure ensures that these robots are not hindered by the latency and bandwidth limitations of cloud-based systems, enabling seamless and continuous operations.

In addition to improving operational efficiency, edge computing enhances the resilience and robustness of industrial robotics systems. By decentralizing data processing, edge computing reduces the risk of system-wide failures and improves the overall security of industrial operations. This decentralized approach aligns with the strategic goals of nations like Saudi Arabia and the UAE, which are investing heavily in smart technologies to bolster their industrial sectors and reduce dependency on oil revenues.

Enhancing Decision-Making and Operational Efficiency

One of the most significant benefits of edge computing in industrial robotics is its ability to enhance decision-making processes. In traditional cloud computing models, data must travel from the source to a centralized server for processing, which can introduce significant delays. Edge computing, however, processes data locally, enabling robots to make decisions in real time. This capability is vital for applications that require immediate responses, such as automated quality inspections, assembly line adjustments, and emergency shutdowns.

In the context of Saudi Arabia’s Vision 2030 and the UAE’s Fourth Industrial Revolution strategies, the adoption of edge computing in industrial robotics is a key component in achieving national goals. These countries are investing in cutting-edge technologies to create smart factories that are highly efficient, scalable, and capable of operating with minimal human intervention. By leveraging edge computing, industrial robots in these smart factories can perform complex tasks with higher accuracy and speed, contributing to increased productivity and competitiveness on a global scale.

Furthermore, edge computing supports the integration of other advanced technologies such as Artificial Intelligence (AI) and the Internet of Things (IoT). AI algorithms can be deployed at the edge to enhance the cognitive capabilities of robots, enabling them to learn from their environment and improve their performance over time. IoT devices can provide real-time data that is processed at the edge, allowing robots to adapt to changing conditions and optimize their operations. This synergy between edge computing, AI, and IoT is driving the evolution of smart manufacturing in the Middle East.

Strategic Implications for Business Success

The strategic implementation of edge computing in industrial robotics has profound implications for business success. Companies that adopt this technology can achieve significant cost savings by reducing reliance on cloud-based services and minimizing network bandwidth usage. Additionally, edge computing can enhance the scalability of industrial operations, allowing businesses to quickly adapt to changes in demand and market conditions. This flexibility is crucial for maintaining a competitive edge in the rapidly evolving industrial landscape of Riyadh, Dubai, and beyond.

Edge computing also plays a vital role in ensuring business continuity and disaster recovery. By processing data locally, industrial robots can continue to operate even in the event of network disruptions or cyber-attacks. This resilience is essential for maintaining uninterrupted production and safeguarding valuable assets. Moreover, the decentralized nature of edge computing can help businesses comply with data sovereignty regulations, which are becoming increasingly stringent in many regions.

For business executives and mid-level managers, understanding the strategic benefits of edge computing is critical for making informed decisions about technology investments. By embracing edge computing, companies can unlock new levels of efficiency, reliability, and scalability in their industrial operations. This technology not only supports the autonomous operation of industrial robots but also provides a foundation for integrating other advanced technologies that drive innovation and growth.

Future Prospects and Technological Advancements

Integrating AI and Machine Learning at the Edge

The future of industrial robotics is closely tied to the integration of Artificial Intelligence (AI) and Machine Learning (ML) at the edge. Edge computing provides the necessary infrastructure to deploy AI and ML algorithms directly on robotic devices, enabling them to process vast amounts of data in real time. This capability allows robots to learn from their experiences, adapt to new situations, and continuously improve their performance. In the industrial sectors of Saudi Arabia and the UAE, this integration is poised to revolutionize manufacturing processes and drive significant advancements in automation.

AI-powered industrial robots can perform tasks with a level of precision and efficiency that was previously unattainable. For example, in predictive maintenance, AI algorithms can analyze data from sensors to predict equipment failures before they occur, allowing for proactive maintenance and reducing downtime. In quality control, AI can detect defects with greater accuracy and speed than human inspectors, ensuring higher product quality and consistency. The ability to process data at the edge further enhances these capabilities, enabling real-time decision-making and immediate corrective actions.

The combination of edge computing, AI, and ML also opens up new possibilities for collaborative robotics, where robots work alongside humans to perform complex tasks. In smart factories, AI-powered robots can assist human workers by taking over repetitive and physically demanding tasks, improving overall productivity and workplace safety. This collaboration is particularly important in the context of the UAE’s and Saudi Arabia’s efforts to create high-tech, sustainable industrial ecosystems that attract global investments and talent.

The Metaverse and Generative AI in Industrial Applications

The concept of the Metaverse, a virtual reality space where users can interact with digital environments and each other, is gaining traction in the industrial sector. Edge computing plays a crucial role in enabling the Metaverse by providing the low-latency, high-bandwidth infrastructure needed to support immersive virtual experiences. In industrial applications, the Metaverse can be used for virtual prototyping, remote maintenance, and employee training, offering new ways to enhance productivity and reduce costs.

Generative AI, a subset of AI that involves creating new content from existing data, is another emerging technology that benefits from edge computing. In industrial robotics, generative AI can be used to design optimized manufacturing processes, create new product prototypes, and develop advanced control algorithms. By processing generative AI models at the edge, companies can achieve faster and more efficient workflows, reducing time-to-market and improving competitiveness.

In conclusion, edge computing is a transformative technology that supports the autonomous operation of industrial robots, driving significant advancements in efficiency, reliability, and scalability. By integrating edge computing with AI, ML, and other emerging technologies, businesses in Saudi Arabia, the UAE, and beyond can unlock new levels of innovation and success. As the industrial landscape continues to evolve, edge computing will remain a critical enabler of smart manufacturing and digital transformation.

#EdgeComputing #IndustrialRobots #SmartManufacturing #AI #ML #Metaverse #GenerativeAI #SaudiArabia #UAE #DigitalTransformation