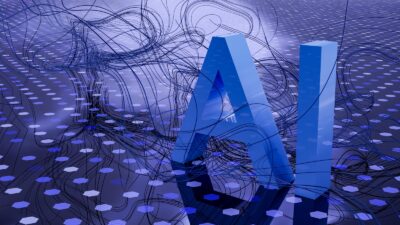

The Catalyst for Enhanced Efficiency and Agility in Manufacturing

The rise of smart factories, characterized by interconnected systems, automation, and data-driven decision-making, is transforming the manufacturing landscape in Saudi Arabia and the UAE. At the heart of this transformation lies edge computing, a technology that enables the real-time processing of data at the source, revolutionizing how manufacturers operate and compete.

Real-Time Insights for Proactive Decision-Making

Edge computing in smart factories empowers manufacturers with real-time insights into their operations. By processing data on the factory floor, close to the machines and sensors generating it, delays associated with transmitting data to distant cloud servers are eliminated. This allows for immediate analysis of production data, equipment performance metrics, and environmental conditions, enabling proactive decision-making and rapid response to anomalies or potential issues.

Optimized Production Processes and Reduced Downtime

With real-time data processing at the edge, manufacturers can optimize their production processes, minimize downtime, and improve overall efficiency. For example, edge devices can analyze data from sensors on a production line to identify bottlenecks, predict equipment failures, and schedule preventive maintenance. This proactive approach reduces the risk of unexpected breakdowns, ensuring continuous production flow and minimizing costly interruptions.

Empowering Autonomous Systems and Robotics

Edge computing plays a crucial role in enabling autonomous systems and robotics in smart factories. Robots and machines equipped with edge computing capabilities can process data locally, allowing them to make real-time decisions and adapt to changing conditions without relying on constant communication with central servers. This autonomy enhances the flexibility and responsiveness of manufacturing processes, enabling faster adaptation to market demands and customized production runs.

Edge Computing: Driving the Future of Manufacturing in the Gulf

Enhanced Quality Control and Product Traceability

Edge computing can significantly enhance quality control and product traceability in smart factories. By analyzing data from cameras and sensors at the edge, manufacturers can quickly identify defects, deviations from specifications, and potential safety hazards. Additionally, edge devices can track products throughout the production process, providing a detailed history of their journey and ensuring compliance with quality standards.

Improved Worker Safety and Productivity

The real-time processing capabilities of edge computing can also improve worker safety and productivity in smart factories. For instance, wearable devices equipped with edge sensors can monitor workers’ vital signs and movements, alerting supervisors to potential fatigue or unsafe conditions. Furthermore, augmented reality (AR) headsets powered by edge computing can provide workers with real-time instructions and guidance, improving efficiency and reducing errors.

A Competitive Advantage in the Global Market

The adoption of edge computing in smart factories is not just a technological upgrade; it’s a strategic imperative for manufacturers in Saudi Arabia and the UAE to remain competitive in the global market. By leveraging the power of real-time data processing, manufacturers can achieve higher levels of operational efficiency, agility, and innovation, positioning themselves as leaders in the era of Industry 4.0.

Data Security and Privacy in Smart Factories

With the increasing reliance on data in smart factories, ensuring data security and privacy becomes paramount. Edge computing offers a significant advantage in this regard by keeping sensitive data within the factory premises. This reduces the risk of unauthorized access and data breaches during transmission to and from the cloud. Edge devices can also employ encryption and other security measures to protect data at rest and in transit.

A Sustainable Approach to Manufacturing

Edge computing aligns with the sustainability goals of Saudi Arabia and the UAE by optimizing energy consumption in smart factories. By processing data locally, edge devices reduce the need for constant data transmission to and from the cloud, which can consume significant energy resources. Additionally, edge computing can enable real-time monitoring of energy usage, allowing manufacturers to identify inefficiencies and implement energy-saving measures.

#EdgeComputing #SmartFactories #RealTimeProcessing #IndustrialAutomation #SaudiArabia #UAE