Enhancing Efficiency in Electronic Device Production

Introduction to Electronic Assembly Robots

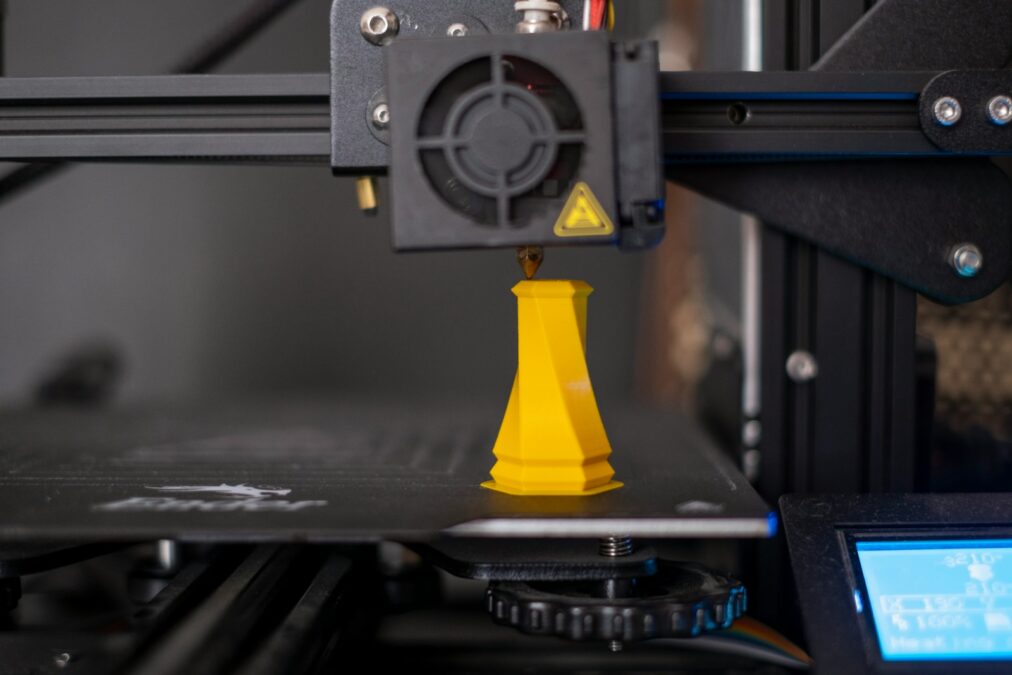

Electronic assembly robots have become indispensable in the manufacturing industry, particularly in countries like Saudi Arabia and the UAE, where technological advancements are embraced. These robots play a crucial role in assembling complex electronic devices with precision and efficiency. Equipped with advanced AI algorithms and robotic arms, electronic assembly robots streamline production processes and ensure consistent quality in the manufacturing of electronic components. By integrating robotics into electronic device assembly, manufacturers can achieve higher productivity and meet the growing demand for consumer electronics.

The adoption of electronic assembly robots represents a significant shift in the manufacturing landscape, offering numerous benefits for businesses and consumers alike. In regions such as Riyadh and Dubai, where innovation drives economic growth, electronic assembly robots are driving advancements in the electronics industry. These robots can perform intricate tasks such as soldering, component placement, and quality inspection with unmatched speed and accuracy. As a result, manufacturers can reduce production costs, minimize defects, and deliver products to market faster, enhancing their competitiveness in the global marketplace.

The Role of AI and Robotics in Electronic Manufacturing

At the core of electronic assembly robots lies artificial intelligence (AI), which enables these systems to analyze data and adapt to changing production requirements in real-time. AI algorithms optimize manufacturing processes, minimize downtime, and improve overall equipment effectiveness (OEE). This level of automation not only increases efficiency but also enhances flexibility, allowing manufacturers to respond quickly to changing consumer demands. In Saudi Arabia and the UAE, where manufacturing excellence is a strategic priority, the integration of AI and robotics is driving innovation and growth in the electronics sector.

Furthermore, the use of blockchain technology in electronic manufacturing offers additional benefits in terms of supply chain transparency and product traceability. Blockchain can be used to record every step of the production process, from component sourcing to final assembly, ensuring accountability and authenticity throughout the supply chain. This level of transparency is essential for maintaining consumer trust and compliance with regulatory requirements. By leveraging AI, robotics, and blockchain, manufacturers in Saudi Arabia and the UAE can ensure the integrity of their electronic products and meet the highest standards of quality and safety.

Executive Coaching and Effective Communication in Implementing Electronic Assembly Robots

The successful integration of electronic assembly robots into manufacturing operations requires effective change management and executive coaching services. Business leaders, production managers, and frontline workers must be equipped with the necessary skills and knowledge to leverage this technology effectively. Executive coaching programs can provide guidance on strategic planning, process optimization, and workforce training, ensuring that organizations maximize the benefits of electronic assembly robots. By empowering leaders with the tools and resources they need, businesses can navigate the complexities of digital transformation and drive sustainable growth.

Effective communication is also essential in ensuring the smooth adoption of electronic assembly robots on the factory floor. Manufacturers must engage with employees at all levels to explain the benefits of robotics and address any concerns or misconceptions. Clear communication channels should be established to facilitate feedback and collaboration, fostering a culture of continuous improvement and innovation. By involving employees in the implementation process and soliciting their input, organizations can build buy-in and ensure a successful transition to robotic-assisted manufacturing.

Moreover, management consulting services can offer valuable insights and support in optimizing the use of electronic assembly robots within manufacturing facilities. Consultants can assist with technology assessment, process redesign, and performance monitoring, helping businesses achieve their productivity and efficiency goals. By leveraging executive coaching, effective communication, and management consulting, manufacturers in Saudi Arabia and the UAE can position themselves for long-term success in the digital age.

The Impact of Electronic Assembly Robots on Manufacturing Excellence

The integration of electronic assembly robots into manufacturing processes has a profound impact on productivity, quality, and competitiveness. These advanced systems enable manufacturers to achieve higher throughput, reduce lead times, and improve product consistency. In regions like Riyadh and Dubai, where manufacturing is a key driver of economic growth, electronic assembly robots are revolutionizing production workflows and driving innovation in the electronics industry.

Furthermore, the data generated by electronic assembly robots provides valuable insights for process optimization and continuous improvement initiatives. By analyzing production metrics and performance data, manufacturers can identify areas for enhancement and implement targeted interventions to drive operational excellence. This data-driven approach to manufacturing ensures that businesses remain agile and responsive to market demands, positioning them for sustained growth and success in the global marketplace.

In conclusion, electronic assembly robots are reshaping the landscape of manufacturing in Saudi Arabia and the UAE, offering unprecedented efficiency and precision in electronic device production. With the support of executive coaching, effective communication, and management consulting, manufacturers can successfully integrate robotic technology into their operations and achieve superior performance. As the adoption of electronic assembly robots continues to grow, the future of manufacturing in the Middle East looks brighter than ever, with enhanced productivity and innovation driving economic prosperity.

—

#ElectronicAssemblyRobots #ManufacturingInnovation #AIinManufacturing #BlockchaininManufacturing #ManufacturingExcellence #ExecutiveCoaching #ChangeManagement #SaudiArabia #UAE #Dubai #Riyadh