Revolutionizing Construction with Advanced Robotics

The Rise of Robotics in Construction

Construction industry robots are transforming the landscape of construction projects across the globe, particularly in innovation-driven regions like Saudi Arabia and the UAE. These robots are designed to perform a variety of tasks, such as bricklaying and welding, which traditionally require significant manual labor and precision. By integrating robotics into construction, companies can achieve higher levels of efficiency, accuracy, and safety.

In Saudi Arabia and Dubai, where ambitious infrastructure projects are continually on the rise, the adoption of construction robots is pivotal. These robots can work tirelessly without the constraints of human fatigue, ensuring consistent quality and speeding up project timelines. For instance, bricklaying robots can lay thousands of bricks per day with perfect alignment and minimal waste, far surpassing human capabilities. Similarly, welding robots provide consistent and high-quality welds, which are crucial for the structural integrity of buildings.

Moreover, the use of robots in construction aligns with the strategic visions of these countries, which emphasize technological advancement and economic diversification. The implementation of advanced robotics not only boosts productivity but also addresses labor shortages and enhances the overall quality of construction projects. This technological shift is a testament to the region’s commitment to fostering innovation and sustaining growth in the construction sector.

Enhancing Efficiency and Safety in Construction

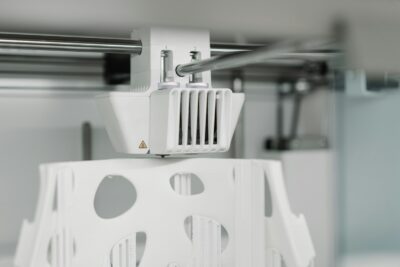

The integration of robotics into construction significantly enhances efficiency by automating repetitive and labor-intensive tasks. This automation allows construction firms to complete projects faster and more cost-effectively. For example, robots equipped with artificial intelligence can be programmed to perform complex tasks such as bricklaying with high precision. This level of automation reduces the time required to complete these tasks and minimizes material waste, leading to substantial cost savings.

In addition to efficiency, safety is a paramount concern in the construction industry. Construction sites are inherently hazardous, with risks of accidents and injuries. By deploying robots for dangerous tasks such as welding, companies can significantly reduce the exposure of human workers to potentially harmful conditions. Robots can operate in extreme environments and perform tasks with precision, thereby mitigating the risk of human error and enhancing overall site safety.

Furthermore, robots are equipped with sensors and advanced monitoring systems that allow for real-time data collection and analysis. This capability provides project managers with critical insights into the progress and condition of construction activities, enabling proactive decision-making and timely interventions. In regions like Riyadh and Dubai, where construction projects are often large-scale and complex, such technological enhancements are invaluable in ensuring project success.

Future Trends and Innovations in Construction Robotics

The future of the construction industry is poised to be increasingly dominated by advanced robotics and automation. Emerging technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT) are expected to further revolutionize the capabilities of construction robots. These advancements will enable robots to learn from their environments, adapt to new tasks, and improve their performance over time.

One of the key trends in construction robotics is the development of autonomous systems that can work collaboratively with human workers. Collaborative robots, or cobots, are designed to assist humans by handling routine tasks while allowing human workers to focus on more complex and decision-intensive activities. This synergy between humans and robots can significantly enhance productivity and job satisfaction.

Additionally, the integration of robotics with building information modeling (BIM) systems is set to transform construction project management. By leveraging BIM, construction robots can access detailed digital models of buildings and infrastructure, enabling precise and efficient execution of tasks. This integration ensures that construction projects are completed to exact specifications, reducing the likelihood of errors and rework.

As the construction industry continues to evolve, the role of robotics will become increasingly prominent. Companies that embrace these technological advancements will be better positioned to compete in the global market, delivering projects with superior quality and efficiency. In the context of Saudi Arabia and the UAE, where infrastructure development is a key priority, the adoption of construction robots is a strategic move that supports national development goals and economic growth.

However, the transition to a robot-centric construction environment also presents challenges that need to be addressed. These include the initial cost of investment, the need for skilled personnel to operate and maintain the robots, and potential resistance to change from the workforce. By proactively addressing these challenges through training programs, incentives, and robust change management strategies, companies can facilitate a smooth transition and maximize the benefits of construction robotics.

—

#constructionrobots, #bricklayingrobots, #weldingrobots, #automation, #innovation, #efficiency, #Riyadh, #Dubai, #smartconstruction, #futureofconstruction, #projectmanagement