The Role of IoT in Predictive Maintenance

IoT-enabled predictive maintenance solutions are revolutionizing the way businesses manage their equipment and assets, particularly in regions like Saudi Arabia and the UAE where industries rely heavily on infrastructure and machinery. By leveraging IoT sensors and advanced analytics, these solutions collect real-time data from equipment, allowing businesses to identify patterns and anomalies that indicate potential failures. In Riyadh and Dubai, where industries such as manufacturing and logistics thrive, the adoption of IoT-enabled predictive maintenance is crucial for maintaining competitiveness and driving business success.

Transforming Maintenance Practices

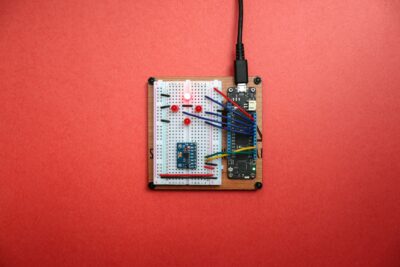

Traditionally, maintenance practices have been reactive, with repairs initiated only after equipment failure occurs. However, IoT-enabled predictive maintenance shifts this paradigm by enabling organizations to anticipate issues before they escalate. In Saudi Arabia’s manufacturing sector, for example, IoT sensors installed on production machinery continuously monitor performance metrics such as temperature, vibration, and energy consumption. By analyzing this data in real-time, businesses can detect signs of wear and tear, identify potential failure points, and take preemptive action to address maintenance needs. This proactive approach not only extends the lifespan of equipment but also improves safety, reduces operational risks, and enhances overall productivity.

The Future of Maintenance Management

As the adoption of IoT-enabled predictive maintenance solutions continues to grow, the landscape of maintenance management is undergoing a significant transformation. In the UAE’s construction industry, for instance, IoT sensors embedded in building systems and infrastructure monitor structural integrity and detect signs of deterioration. By harnessing the power of IoT analytics, construction companies can ensure the safety and longevity of their projects while optimizing resource allocation and project timelines. Across various sectors in Saudi Arabia and the UAE, from healthcare to transportation, the integration of IoT into maintenance practices is paving the way for a smarter, more efficient future, where equipment downtime is minimized, and business operations run seamlessly.

Enhancing Asset Performance

One of the key benefits of IoT-enabled predictive maintenance is its ability to enhance asset performance by providing actionable insights into equipment health and utilization. In Saudi Arabia’s oil and gas sector, where equipment downtime can result in significant financial losses, IoT sensors deployed on drilling rigs and refineries monitor critical parameters such as pressure, temperature, and fluid flow. By analyzing this data in real-time, operators can optimize maintenance schedules, prevent costly breakdowns, and maximize production output. Similarly, in the UAE’s aviation industry, airlines leverage IoT-enabled predictive maintenance to monitor aircraft engines, avionics systems, and cabin components, ensuring passenger safety and operational efficiency.

Driving Cost Savings and Sustainability

Besides improving operational efficiency and asset reliability, IoT-enabled predictive maintenance solutions also drive cost savings and support sustainability initiatives. In Saudi Arabia’s power generation sector, for example, utility companies utilize IoT sensors to monitor the performance of turbines, generators, and transmission lines. By identifying inefficiencies and addressing maintenance needs proactively, these companies can reduce energy wastage, lower maintenance costs, and minimize environmental impact. Similarly, in the UAE’s hospitality sector, IoT-enabled maintenance solutions help hotels and resorts optimize energy usage, reduce water consumption, and enhance guest comfort, contributing to both cost savings and environmental sustainability.

Embracing Digital Transformation

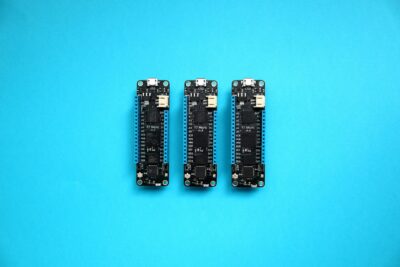

The adoption of IoT-enabled predictive maintenance represents a significant step towards embracing digital transformation and staying ahead in today’s competitive business landscape. In Saudi Arabia and the UAE, where innovation is driving economic growth, businesses that leverage IoT technologies to optimize maintenance practices gain a competitive edge. By integrating IoT data with advanced analytics, machine learning, and AI algorithms, organizations can unlock new insights, streamline operations, and drive continuous improvement. As the digital revolution continues to unfold, IoT-enabled predictive maintenance will play a pivotal role in shaping the future of maintenance management across industries in the Middle East.

#IoT #PredictiveMaintenance #BusinessEfficiency #SaudiArabia #UAE #Riyadh #Dubai #Manufacturing #Logistics #Construction #MaintenanceManagement #DigitalTransformation