The Role of IIoT in Advancing Industry 4.0 and Smart Manufacturing

Leveraging IIoT for Enhanced Connectivity and Automation

The integration of IIoT solutions for smart factories and Industry 4.0 represents a pivotal step in the evolution of manufacturing, particularly in forward-looking regions like Saudi Arabia and the UAE. As Riyadh and Dubai aim to position themselves at the forefront of the global industrial revolution, the adoption of Industrial Internet of Things (IIoT) technologies is becoming essential. IIoT provides the connectivity, data analytics, and automation capabilities required to transform traditional manufacturing facilities into smart factories, where machines, systems, and people work in harmony to optimize production processes.

One of the fundamental ways IIoT supports the development of smart factories is through enhanced connectivity. IIoT devices, such as sensors, actuators, and smart machines, are interconnected to form a cohesive network that enables real-time data exchange and communication. This connectivity allows manufacturers to monitor and control production processes with unprecedented precision, ensuring that every aspect of the factory operates efficiently. In Riyadh, for example, a manufacturing plant implemented IIoT sensors on their assembly lines to track machine performance and detect anomalies early. This proactive approach not only reduced downtime but also improved the overall reliability of their operations, contributing to a more agile and responsive manufacturing environment.

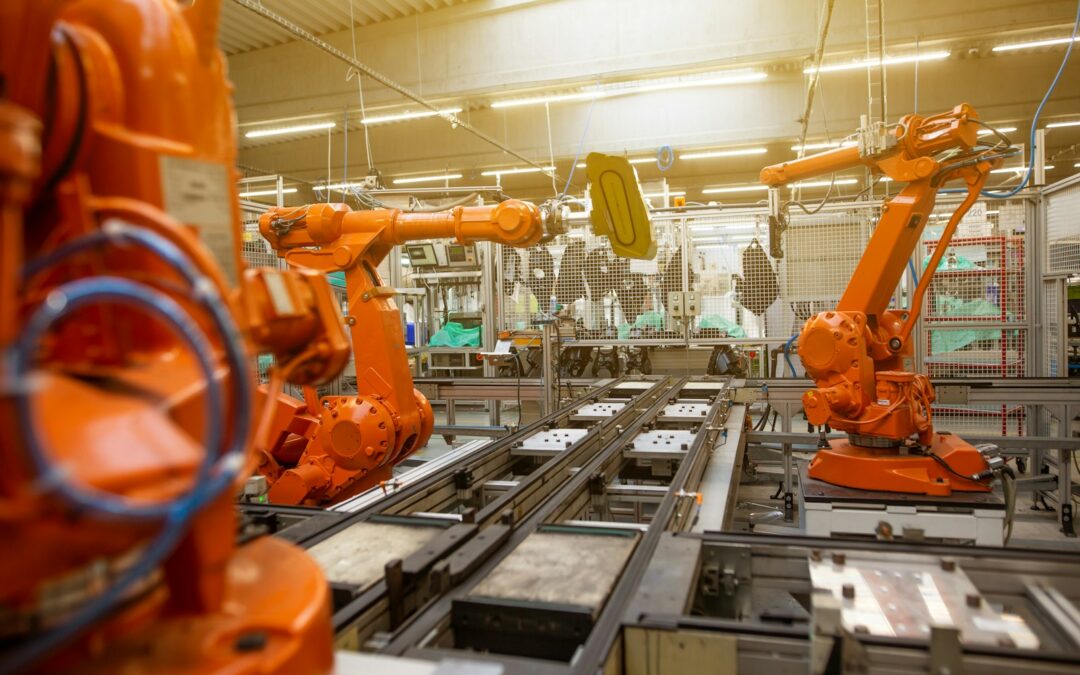

Furthermore, IIoT solutions facilitate automation by integrating with advanced technologies such as robotics and AI-driven analytics. By automating repetitive tasks and optimizing workflows, IIoT enhances productivity while reducing the likelihood of human error. In Dubai, companies are leveraging IIoT-enabled robots to handle complex assembly tasks, improving precision and speed. This not only increases output but also allows human workers to focus on more strategic and innovative roles, driving the overall efficiency of the factory. The combination of connectivity and automation positions IIoT as a cornerstone of Industry 4.0, enabling factories to achieve new levels of operational excellence.

Optimizing Production with Data-Driven Decision Making

Another critical advantage of IIoT solutions for smart factories and Industry 4.0 is the ability to harness data for informed decision-making. In a smart factory, IIoT devices continuously collect data on various aspects of the production process, from machine performance to energy usage. This data is then analyzed using advanced algorithms and machine learning models, providing insights that help manufacturers optimize production, reduce waste, and enhance product quality.

In Saudi Arabia, manufacturers are using IIoT data to implement predictive maintenance strategies that anticipate equipment failures before they occur. By analyzing data from sensors monitoring vibration, temperature, and other key metrics, companies can schedule maintenance at the most opportune times, minimizing disruptions and extending the lifespan of their equipment. This data-driven approach not only improves the reliability of production but also reduces maintenance costs, contributing to a more sustainable and cost-effective operation.

Additionally, IIoT supports real-time process optimization by providing visibility into every stage of the manufacturing process. By analyzing data from the factory floor, manufacturers can identify bottlenecks, adjust production schedules, and allocate resources more effectively. In Dubai, a smart factory used IIoT data to optimize its energy consumption, adjusting machine operations to align with periods of lower energy costs. This not only reduced operational expenses but also supported the factory’s sustainability goals, demonstrating the value of IIoT in driving both economic and environmental benefits.

Implementing IIoT for Industry 4.0: Strategies and Best Practices

Ensuring Scalability and Interoperability in IIoT Deployments

For IIoT solutions for smart factories and Industry 4.0 to be successful, scalability and interoperability are crucial factors that need careful consideration. As factories grow and evolve, their IIoT systems must be capable of scaling to accommodate new devices, increased data volumes, and expanding production lines. This requires a robust infrastructure that supports seamless integration of new technologies without compromising system performance or reliability.

One effective strategy is to adopt open standards and protocols that facilitate interoperability between different IIoT devices and platforms. By using open standards, manufacturers can ensure that their IIoT systems remain flexible and adaptable, allowing them to integrate new technologies as they become available. In Riyadh, a leading manufacturer adopted a standards-based approach to their IIoT deployment, enabling them to integrate devices from multiple vendors without encountering compatibility issues. This flexibility allowed the company to scale their IIoT system in line with their business growth, ensuring that their smart factory remained at the cutting edge of technological innovation.

Moreover, cloud computing plays a vital role in supporting the scalability of IIoT solutions. Cloud platforms provide the computational power and storage capacity needed to process the vast amounts of data generated by IIoT devices. By leveraging cloud-based IIoT solutions, manufacturers can scale their operations without the need for significant upfront investment in physical infrastructure. In Dubai, a smart factory utilized cloud services to manage data from its IIoT network, allowing it to scale rapidly in response to changing market demands. This approach not only supported the factory’s scalability but also enabled real-time data analytics, providing actionable insights that enhanced overall production efficiency.

Conclusion: Embracing IIoT for the Future of Manufacturing

The deployment of IIoT solutions for smart factories and Industry 4.0 is redefining the landscape of manufacturing in Saudi Arabia and the UAE, offering companies the tools needed to achieve unprecedented levels of efficiency, flexibility, and competitiveness. By leveraging IIoT to enhance connectivity, automate processes, and optimize data-driven decision-making, manufacturers can transform their operations into intelligent, responsive, and sustainable enterprises. As Industry 4.0 continues to evolve, embracing IIoT will be essential for staying ahead of the curve and capitalizing on the opportunities presented by the next industrial revolution. Through strategic planning, investment in scalable solutions, and a commitment to innovation, businesses can harness the full potential of IIoT, driving success in the era of smart manufacturing.

—

#IIoT #SmartFactories #Industry4.0 #DigitalTransformation #SaudiArabia #UAE #Riyadh #Dubai #ModernTechnology #BusinessSuccess #IndustrialIoT