Streamlining Operations for Optimal Efficiency and Productivity

The concept of “Enhance lean manufacturing with visual workflow tools” is gaining traction among business executives, mid-level managers, and entrepreneurs. This article, poised in a formal and authoritative tone, aims to provide an informational and persuasive overview on how integrating visual workflow tools can revolutionize lean manufacturing. We will explore various aspects such as change management, the benefits of executive coaching services, the importance of effective communication in ensuring business success, and the emerging role of Generative Artificial Intelligence in enhancing leadership and management skills. Additionally, this article will touch upon the latest business news updates and project management trends.

The Importance of Lean Manufacturing

Lean manufacturing, a systematic approach to waste reduction, transcends mere operational improvements; it serves as a strategic catalyst for achieving long-term competitiveness. By focusing on eliminating non-value-added activities and optimizing workflows, lean methodologies empower organizations to enhance productivity, reduce costs, and drive sustainable growth. Integrating visual workflow tools within the lean framework further amplifies these benefits by providing real-time insights, enhancing operational clarity, and empowering teams to make data-driven decisions.

1. Enhancing Transparency and Collaboration: Visual workflow tools provide a transparent and centralized view of the production process, allowing stakeholders across departments and teams to readily understand the flow of work and identify potential bottlenecks. This fosters collaboration, facilitates communication, and empowers teams to address issues proactively, improving overall efficiency and responsiveness.

2. Optimizing Workflow and Minimizing Waste: Visual tools enable the identification and elimination of non-value-added activities within the workflow. By visualizing bottlenecks, inefficiencies, and idle time, organizations can analyze production data, optimize process flow, and implement targeted improvements, leading to significant reductions in waste and increased productivity.

3. Empowering Data-Driven Decision-Making: Visual dashboards and real-time data visualization tools equip team members with the insights needed to make informed decisions at the point of work. By readily accessing key performance indicators and production data, teams can identify areas for improvement, adjust processes in real-time, and ensure continuous optimization of the production line.

4. Fostering a Culture of Continuous Improvement: Visual workflow tools provide a platform for continuous learning and improvement by enabling teams to track progress, analyze trends, and identify areas for further optimization. This data-driven approach fosters a culture of continuous learning, empowers employees to contribute to improvement efforts, and ensures the organization remains adaptable and responsive to changing market demands.

5. Enhancing Employee Engagement and Motivation: Visual tools create a more engaging and motivating work environment by providing employees with a clear understanding of their role and contribution to the overall production process. This transparency allows employees to take ownership of their work, promotes accountability, and fosters a sense of collective responsibility for achieving production goals.

6. Facilitating Problem-Solving and Root Cause Analysis: Visual tools allow teams to quickly identify and analyze production issues, enabling them to identify root causes efficiently. By visualizing the workflow and readily accessing relevant data, teams can collaboratively brainstorm solutions, implement corrective actions, and prevent similar problems from recurring in the future.

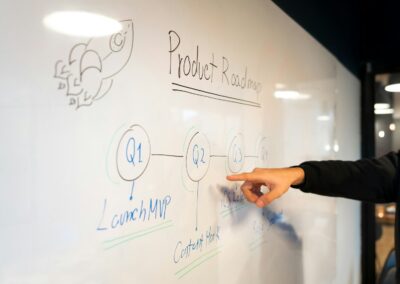

Visual Workflow Tools: Enhancing Efficiency

Visual workflow tools are instrumental in streamlining manufacturing processes. These tools provide a clear and concise visual representation of workflows, enabling easy identification of bottlenecks and inefficiencies. By simplifying complex processes into easy-to-understand visuals, they facilitate better decision-making and process optimization.

Change Management in Implementing Visual Tools

Implementing visual workflow tools requires effective change management strategies. It involves a shift in the traditional way of operating, necessitating training and adaptation among staff. This transition can be smoothly managed through effective communication and leadership, ensuring all team members are aligned with the new approach.

Executive Coaching for Effective Implementation

Executive coaching services play a pivotal role in equipping leaders with the necessary skills for implementing visual workflow tools in lean manufacturing. Coaches can help leaders develop strategies for effective integration, fostering a culture of continuous improvement and innovation within their teams.

Leveraging Generative AI in Manufacturing

Generative AI is emerging as a powerful tool in enhancing lean manufacturing processes. It can be used to create and refine visual workflows, making them more efficient and adaptive to changing business needs. This technology not only optimizes manufacturing processes but also assists in predictive maintenance and resource planning.

Project Management in Lean Manufacturing

Effective project management is essential in the successful implementation of visual workflow tools in lean manufacturing. It involves careful planning, resource allocation, and continuous monitoring to ensure that the integration of these tools aligns with the company’s operational goals and objectives.

Staying Informed with Business News Updates

Keeping abreast of the latest trends and developments in lean manufacturing and visual workflow tools is vital for businesses. Regular updates can provide insights into new technologies and methodologies, helping companies stay competitive and agile in a rapidly evolving business landscape.

Conclusion Enhance lean manufacturing with visual workflow tools

In summary, enhancing lean manufacturing with visual workflow tools is a strategic move towards achieving greater efficiency and productivity. It represents an intersection of innovation and practicality, offering tangible benefits in operational management. As businesses continue to evolve, adopting these advanced tools and methodologies will be key to maintaining a competitive edge.

#LeanManufacturing #VisualWorkflow #OperationalEfficiency #BusinessInnovation #ManufacturingExcellence