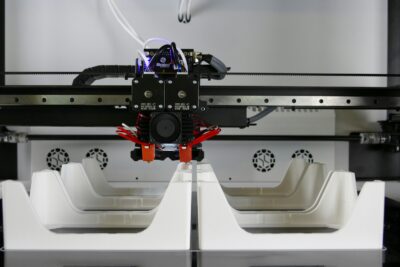

Revolutionizing Packaging with Additive Manufacturing Technology

Innovative Approach to Packaging Design

The advent of additive manufacturing has revolutionized the way functional packaging solutions are conceived and produced. Unlike traditional manufacturing methods, which often rely on molds and mass production, additive manufacturing allows for the creation of intricate designs and customized solutions tailored to specific needs. In regions like Saudi Arabia and the UAE, where innovation is a driving force in the business landscape, this technology is reshaping the packaging industry, offering unprecedented opportunities for creativity and efficiency.

In Riyadh and Dubai, businesses are harnessing the power of additive manufacturing to develop packaging solutions that not only protect and preserve products but also enhance their functionality and appeal. From customized packaging for luxury goods to eco-friendly solutions for sustainable products, the possibilities are endless. Additive manufacturing enables designers to experiment with new materials and geometries, pushing the boundaries of conventional packaging design and delivering unique solutions that stand out in the market.

Advantages of Additive Manufacturing in Packaging

The advantages of additive manufacturing in packaging are manifold. Firstly, it allows for rapid prototyping and iteration, enabling designers to quickly test and refine their ideas before full-scale production. This iterative approach not only reduces time-to-market but also minimizes the risk of costly errors and waste. Additionally, additive manufacturing offers greater flexibility in production, allowing for on-demand manufacturing and customization without the need for expensive tooling or inventory.

Moreover, additive manufacturing enables the creation of complex geometries and lightweight structures that are difficult or impossible to achieve with traditional manufacturing methods. This opens up new possibilities for packaging design, allowing for innovative features such as integrated handles, compartments, and closures. By optimizing the design for both form and function, businesses can enhance the user experience and differentiate their products in a competitive market.

Integration with Emerging Technologies

Furthermore, additive manufacturing is increasingly being integrated with emerging technologies such as Artificial Intelligence (AI), Blockchain, and the Metaverse to further enhance packaging solutions. AI algorithms can optimize packaging designs for specific requirements, taking into account factors such as product fragility, transportation logistics, and environmental impact. Blockchain technology ensures the traceability and authenticity of packaging materials, providing greater transparency and trust throughout the supply chain.

In addition, the Metaverse offers new opportunities for interactive and immersive packaging experiences, allowing consumers to virtually interact with products before making a purchase. This digital integration not only enhances the marketing and branding of products but also provides valuable data insights into consumer preferences and behavior. By leveraging these technologies, businesses can create packaging solutions that not only meet functional requirements but also deliver engaging and memorable experiences for consumers.

Conclusion: The Future of Packaging

In conclusion, additive manufacturing is revolutionizing the packaging industry, offering a new paradigm for the creation of functional and innovative solutions. In Saudi Arabia and the UAE, where innovation is a key driver of economic growth, businesses are increasingly turning to additive manufacturing to develop packaging that not only protects and preserves products but also enhances their value and appeal. By embracing this technology and integrating it with emerging technologies such as AI, Blockchain, and the Metaverse, businesses can unlock new possibilities and stay ahead of the competition in the dynamic and evolving market landscape.

Furthermore, the adoption of additive manufacturing for packaging solutions aligns with broader sustainability initiatives in Saudi Arabia and the UAE. By utilizing lightweight materials and optimizing designs for resource efficiency, businesses can reduce the environmental footprint of their packaging operations while meeting consumer demand for eco-friendly products. This commitment to sustainability not only enhances brand reputation but also contributes to the long-term viability of the business.

Moreover, the integration of additive manufacturing into packaging processes presents opportunities for collaboration and partnership across industries. By working together with suppliers, manufacturers, and technology providers, businesses can leverage collective expertise and resources to drive innovation and address common challenges in packaging design and production. This collaborative approach fosters a culture of continuous improvement and ensures that businesses remain at the forefront of industry developments, delivering value to both consumers and stakeholders alike.

—

#functionalpackagingsolutions #additivemanufacturing #SaudiArabia #UAE #Riyadh #Dubai #changemanagement #executivecoachingservices #effectivecommunication #businesssuccess #managementconsulting #ArtificialIntelligence #Blockchain #TheMetaverse #GenerativeArtificialIntelligence #leadershipandmanagementskills #projectmanagement