Revolutionizing Production Processes Through IoT

Transforming Flexibility and Responsiveness

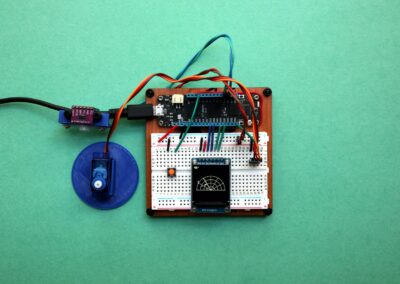

The integration of Internet of Things (IoT) technology is a game-changer for manufacturing, offering unprecedented Manufacturing Flexibility and responsiveness in production processes. By deploying IoT devices and systems, manufacturers in Saudi Arabia and the UAE can enhance their operational efficiency and adaptability to changing market demands. IoT enables real-time data collection and analysis, which is crucial for optimizing production lines and responding swiftly to disruptions.

For instance, IoT sensors embedded in manufacturing equipment provide continuous monitoring of machinery performance, detecting potential issues before they escalate. This proactive approach allows for timely maintenance and adjustments, reducing downtime and ensuring that production remains uninterrupted. In cities like Riyadh and Dubai, where industrial growth is rapid, leveraging IoT for such capabilities ensures that manufacturing processes can adapt quickly to new product requirements or unexpected changes in demand.

Enabling Real-Time Data-Driven Decision Making

IoT integration in manufacturing provides the advantage of real-time data-driven decision-making, enhancing the ability to respond to immediate challenges and opportunities. With IoT systems, manufacturers can collect and analyze data from various stages of production, gaining valuable insights into operational efficiency and product quality. This level of visibility allows for more informed decisions and strategic adjustments to production schedules and processes.

In the context of manufacturing facilities across Dubai and Riyadh, this means that companies can rapidly adapt to fluctuations in market demand, optimize resource allocation, and improve overall productivity. By harnessing IoT data, manufacturers can also implement just-in-time production strategies, reducing inventory costs and minimizing waste. This agility not only supports business growth but also ensures that companies remain competitive in a dynamic industry landscape.

Enhancing Collaboration and Workflow Efficiency

The integration of IoT in manufacturing fosters enhanced collaboration and workflow efficiency by connecting various elements of the production process. IoT systems enable seamless communication between different machinery, departments, and even supply chain partners. This interconnectedness ensures that information flows smoothly and that all parts of the production process are aligned and coordinated effectively.

In Saudi Arabia and the UAE, where large-scale manufacturing operations are common, IoT facilitates a more cohesive and synchronized approach to production management. For example, IoT technology can automate data sharing between production lines and supply chain systems, ensuring that inventory levels, order statuses, and production schedules are consistently updated and managed. This integration reduces delays, minimizes errors, and enhances overall operational efficiency.

Driving Innovation and Strategic Leadership in Manufacturing

Leveraging AI and Generative Technologies for Advanced Production

The combination of IoT with Artificial Intelligence (AI) and generative technologies is driving significant advancements in manufacturing. AI algorithms, when integrated with IoT systems, can analyze vast amounts of data to identify patterns, predict maintenance needs, and optimize production processes. This fusion of technologies enables manufacturers to achieve higher levels of precision and innovation in their production operations.

In cities like Dubai and Riyadh, where technological innovation is a key focus, the integration of AI and IoT allows for the development of sophisticated manufacturing systems. Generative AI, for instance, can be used to design and test new production methods or products virtually before implementation. This capability not only accelerates the innovation process but also enhances the ability to adapt to evolving market demands and technological advancements.

Strengthening Project Management and Leadership Skills

Effective project management and leadership are crucial for successfully integrating IoT into manufacturing processes. Leaders in the industry must navigate the complexities of implementing new technologies, managing change, and ensuring that production systems align with business objectives. Executive coaching services play a pivotal role in developing the skills necessary for leading such transformative projects.

In the context of manufacturing in Saudi Arabia and the UAE, executive coaching can provide valuable support to leaders overseeing IoT integration projects. By focusing on strategic planning, change management, and technology adoption, coaching services help ensure that manufacturing operations leverage IoT effectively and achieve their desired outcomes. Strong leadership and project management are essential for driving innovation and maintaining competitiveness in a rapidly evolving industry landscape.

Future-Proofing Manufacturing with Scalable IoT Solutions

As manufacturing technologies continue to evolve, it is essential for companies to future-proof their operations with scalable IoT solutions. Scalable IoT systems can adapt to increasing production demands, new technologies, and changing business requirements. This adaptability ensures that manufacturing processes remain efficient and responsive as the industry progresses.

In Dubai and Riyadh, where the manufacturing sector is rapidly advancing, investing in scalable IoT solutions is key to sustaining growth and success. By implementing flexible and expandable systems, manufacturers can stay ahead of technological trends and industry developments. This forward-thinking approach ensures that production processes are not only optimized for current needs but also prepared for future advancements and challenges.

Conclusion

The integration of IoT technology in manufacturing is revolutionizing production processes by enhancing flexibility, responsiveness, and efficiency. Through real-time data, predictive analytics, and advanced AI capabilities, manufacturers in Saudi Arabia and the UAE are transforming their operations to meet evolving market demands and technological advancements. By focusing on innovation, strategic leadership, and scalable solutions, companies can achieve greater success and maintain a competitive edge in the manufacturing industry.

—

#IoTInManufacturing #FlexibleProduction #ResponsiveManufacturing #SmartManufacturing #AIInIndustry #GenerativeAI #LeadershipInManufacturing #ProjectManagementInManufacturing #ModernTechnology #ManufacturingInnovation