How AI-Driven IoT Solutions Revolutionize Predictive Maintenance in Manufacturing

The Role of AI-Driven IoT Solutions for Predictive Maintenance in Manufacturing

The use of AI-driven IoT solutions for predictive maintenance in manufacturing is transforming industries in Saudi Arabia, the UAE, and other tech-forward regions. As manufacturers seek to improve operational efficiency and reduce downtime, predictive maintenance powered by AI and IoT provides a cutting-edge approach to equipment management. By utilizing real-time data from IoT devices combined with AI algorithms, manufacturers can predict when machinery is likely to fail and take proactive steps to address issues before they lead to costly disruptions.

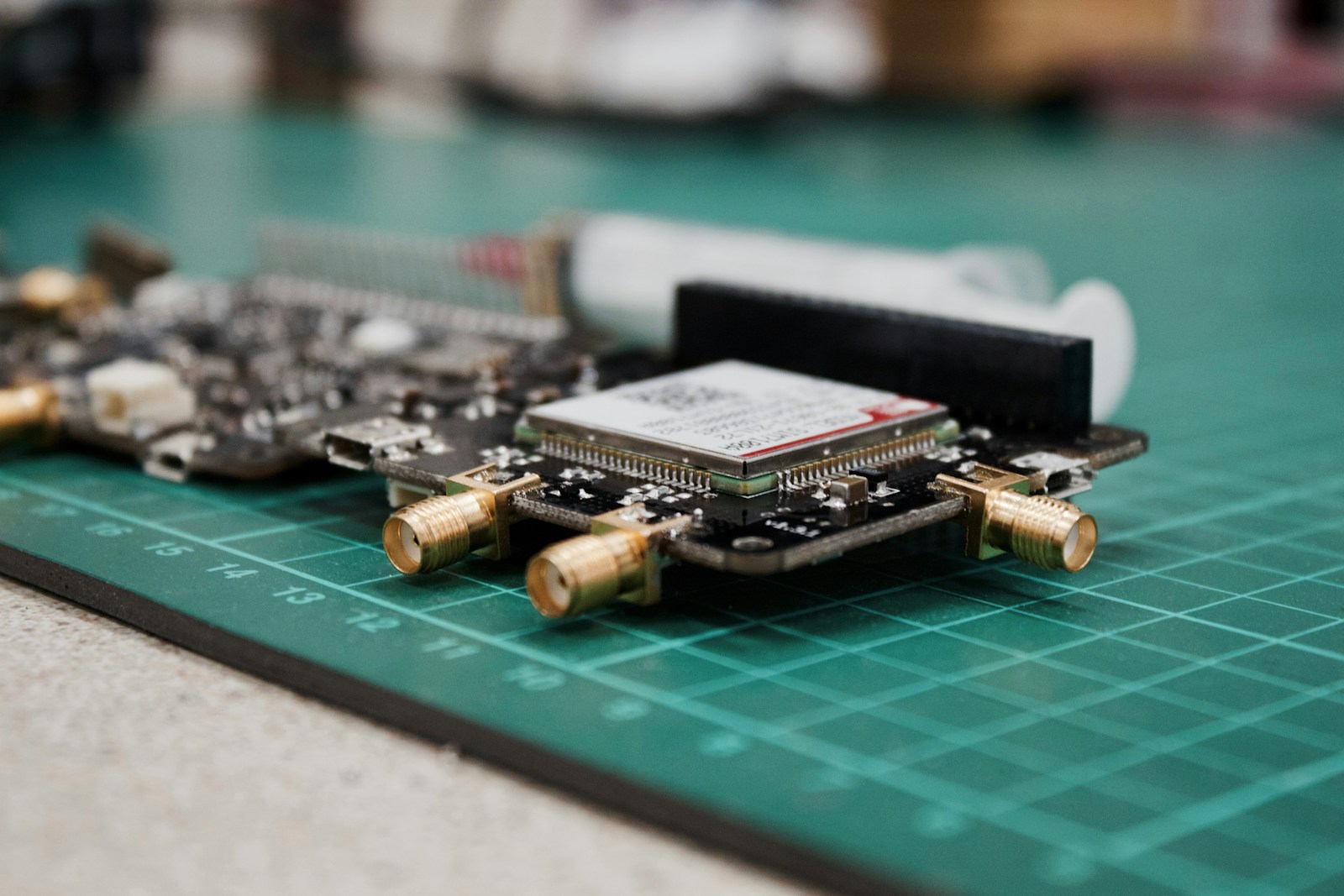

In the bustling industrial hubs of Riyadh and Dubai, where manufacturing is a critical component of economic growth, AI-driven predictive maintenance offers substantial benefits. For example, sensors attached to equipment can continuously monitor factors such as vibration, temperature, and pressure, feeding data into AI models that analyze these inputs for signs of wear or malfunction. This real-time analysis allows for early detection of potential problems, enabling maintenance teams to address issues during scheduled downtimes rather than facing unexpected failures that can halt production lines.

Moreover, AI-driven IoT solutions optimize maintenance schedules by moving from a reactive or time-based approach to a condition-based strategy. Traditional maintenance methods often involve routine checks that may not align with the actual condition of the equipment, leading to unnecessary maintenance or missed opportunities to prevent breakdowns. With predictive maintenance, manufacturers can tailor their maintenance activities to the specific needs of each piece of equipment, maximizing asset life and minimizing unplanned downtime. This not only improves operational efficiency but also significantly reduces maintenance costs, providing a competitive advantage in the fast-paced markets of Saudi Arabia and the UAE.

Improving Efficiency and Reducing Costs with AI-Driven Predictive Maintenance

One of the most significant benefits of AI-driven IoT solutions for predictive maintenance in manufacturing is the potential to drastically improve operational efficiency and reduce costs. By leveraging AI algorithms to analyze data from connected devices, manufacturers can gain valuable insights into equipment health and performance, allowing them to optimize their maintenance strategies. This predictive approach helps avoid the high costs associated with unexpected equipment failures, which can disrupt production schedules and lead to lost revenue.

In Saudi Arabia’s expanding manufacturing sector, where efficiency and reliability are paramount, predictive maintenance powered by AI and IoT can play a crucial role in maintaining a competitive edge. For instance, by predicting when a critical piece of machinery is likely to fail, manufacturers can preemptively order replacement parts and schedule maintenance during off-peak hours, minimizing disruption to production. This proactive maintenance strategy not only extends the lifespan of equipment but also reduces the inventory costs associated with keeping spare parts on hand.

Additionally, predictive maintenance can lead to significant energy savings by optimizing equipment performance. AI-driven IoT solutions can identify inefficiencies in machinery that may be consuming more energy than necessary, such as motors running hotter than optimal temperatures or components operating under excessive strain. By addressing these inefficiencies early, manufacturers in Dubai and Riyadh can reduce their energy consumption, lower operating costs, and contribute to sustainability goals. This alignment with broader environmental objectives is increasingly important as both Saudi Arabia and the UAE pursue ambitious plans for sustainable industrial growth.

Enhancing Safety and Compliance with AI-Driven IoT Solutions

The application of AI-driven IoT solutions for predictive maintenance in manufacturing also contributes to enhanced safety and regulatory compliance. In industries where heavy machinery and complex processes are involved, maintaining equipment in optimal condition is critical for ensuring the safety of workers. Predictive maintenance helps prevent accidents by identifying potential equipment failures that could pose a safety hazard, such as overheating motors or worn-out parts that could lead to malfunctions.

For manufacturers in Riyadh and Dubai, where safety standards are rigorously enforced, AI-driven predictive maintenance offers a valuable tool for maintaining compliance with local regulations. By continuously monitoring equipment conditions and automatically generating maintenance alerts, these solutions help manufacturers stay ahead of regulatory requirements, avoiding fines and ensuring that their operations meet the highest safety standards. Furthermore, AI-driven IoT solutions can provide detailed reports and audit trails that demonstrate compliance, simplifying the process of meeting regulatory obligations.

Moreover, predictive maintenance can improve the overall reliability of manufacturing operations by ensuring that equipment is always functioning at peak performance. This reliability is crucial for maintaining customer satisfaction, especially in industries where timely delivery and product quality are critical. By reducing the likelihood of unexpected breakdowns and ensuring consistent production output, manufacturers can build stronger relationships with their customers and enhance their reputation in the market.

Challenges and Strategies for Implementing AI-Driven Predictive Maintenance

While the benefits of AI-driven IoT solutions for predictive maintenance in manufacturing are significant, their implementation comes with challenges that businesses must navigate. One of the primary challenges is the integration of AI and IoT technologies into existing manufacturing systems. Many manufacturers operate with legacy equipment that may not be compatible with modern IoT devices, requiring significant investment in upgrades or retrofitting. However, the long-term benefits of enhanced efficiency and reduced downtime often justify the initial investment.

Another challenge is the need for skilled personnel to develop, manage, and interpret AI-driven predictive maintenance models. As the demand for data scientists and AI specialists continues to grow, manufacturers may face difficulties in attracting and retaining the talent needed to drive their predictive maintenance initiatives. To overcome this, companies in Saudi Arabia and the UAE can explore partnerships with technology providers, invest in training programs, and leverage automated AI platforms that simplify the deployment of predictive maintenance solutions.

Additionally, data security and privacy are critical considerations when implementing AI-driven IoT solutions. As these systems collect and analyze vast amounts of data from connected devices, ensuring that this data is protected from cyber threats is essential. Manufacturers must implement robust cybersecurity measures, such as encryption, access controls, and continuous monitoring, to safeguard their IoT ecosystems. By prioritizing security, businesses can mitigate the risks associated with data breaches and ensure that their predictive maintenance solutions operate safely and reliably.

Conclusion: The Future of AI-Driven Predictive Maintenance in Manufacturing

The adoption of AI-driven IoT solutions for predictive maintenance in manufacturing is set to revolutionize the way industries approach equipment management and operational efficiency. For businesses in Saudi Arabia, the UAE, and other forward-thinking regions, embracing predictive maintenance offers a pathway to greater reliability, cost savings, and competitive advantage. By leveraging AI-driven insights, manufacturers can optimize their maintenance strategies, reduce downtime, and enhance the safety and compliance of their operations.

As the manufacturing landscape continues to evolve, the integration of AI-driven IoT solutions will become increasingly critical. For business executives, mid-level managers, and entrepreneurs, understanding the value of predictive maintenance and strategically implementing these solutions is essential for staying ahead in a rapidly changing market. The future of manufacturing is intelligent, and those who invest in AI-driven predictive maintenance today will be well-positioned to lead the industry and capitalize on the opportunities of tomorrow.

—

#AIDrivenIoTSolutions #PredictiveMaintenance #ManufacturingEfficiency #DigitalTransformation #SaudiArabiaTech #UAETechnology #SmartManufacturing #DubaiTech #RiyadhInnovation #IndustrialIoT