Optimizing Mineral Processing through Advanced Reagent Use

The Role of Collectors in Flotation Efficiency

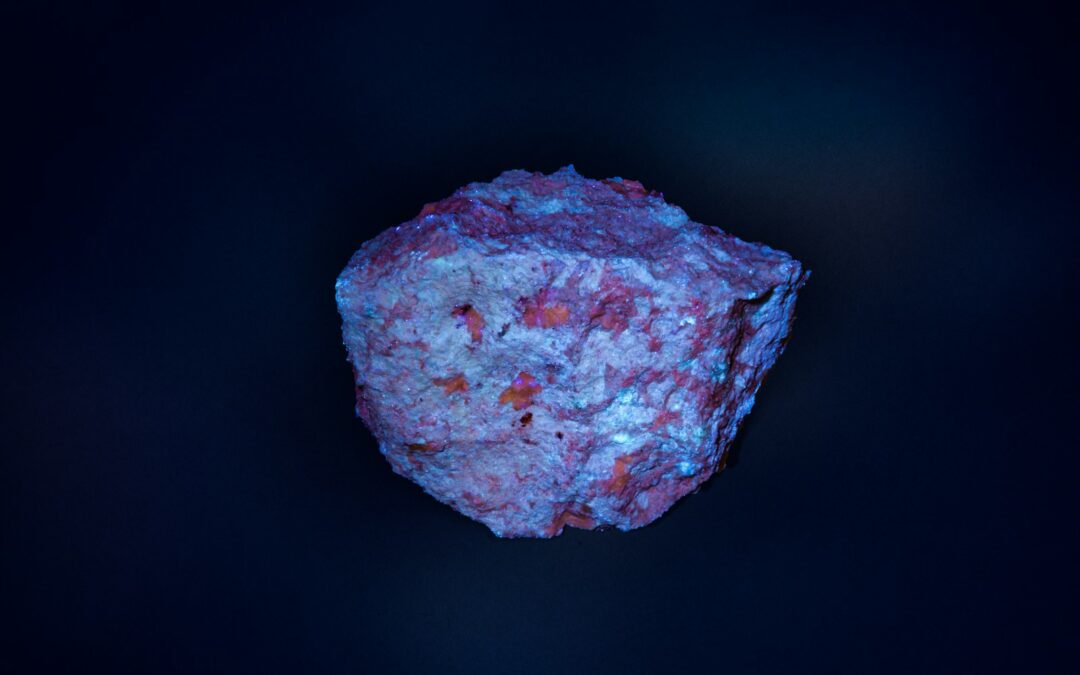

Enhancing mineral separation efficiency with flotation reagents is a critical aspect of modern mineral processing. Collectors, one of the primary reagents used in flotation, play a vital role in increasing the hydrophobicity of targeted minerals, facilitating their attachment to air bubbles and subsequent separation from the ore slurry. This process is especially significant in regions like Saudi Arabia and the UAE, where mining is a cornerstone of economic development. By utilizing advanced collectors, mining operations in Riyadh and Dubai can achieve higher recovery rates, improve the quality of concentrates, and enhance overall operational efficiency.

The Importance of Frothers in Froth Stability

Frothers are another essential reagent in the flotation process. They are used to produce a stable froth layer at the top of the flotation cell, which aids in the separation of valuable minerals from the waste material. The effectiveness of frothers directly impacts the efficiency of mineral recovery. In high-profile business environments such as those in Saudi Arabia and the UAE, employing the right frothers can significantly reduce operational costs and increase profitability. Frothers contribute to the formation of a consistent and manageable froth, ensuring that the maximum amount of target minerals is recovered from each batch of ore processed.

Modifiers and Their Impact on Selectivity

Modifiers, also known as regulators, are used to alter the chemical environment of the flotation cell, thereby enhancing the selectivity of the process. These reagents can depress unwanted minerals or activate desired ones, depending on the specific needs of the mineral processing operation. In cities like Riyadh and Dubai, where mining companies strive for excellence and efficiency, the use of modifiers can lead to more precise separation processes. By optimizing the chemical conditions within the flotation cell, modifiers ensure that only the target minerals are collected, improving the purity and quality of the final product.

Change Management in Mining Operations

Implementing advanced flotation technologies and reagents requires effective change management strategies. Change management involves preparing, supporting, and helping individuals and teams in transitioning to new processes and technologies. For mining companies in Saudi Arabia and UAE, successful change management is crucial for overcoming resistance to new technologies and fostering a culture of continuous improvement. This includes comprehensive training programs, stakeholder engagement, and transparent communication to ensure that all employees are aligned with the organization’s innovation goals.

The Role of Executive Coaching Services

Executive coaching services play a vital role in facilitating the successful adoption of advanced flotation technologies. Executive coaches work with business leaders to develop the strategic vision and leadership skills necessary to drive technological innovation. In the mining sectors of Riyadh and Dubai, coaches provide valuable insights and strategies for overcoming challenges associated with technological adoption. This includes enhancing leadership capabilities, improving decision-making processes, and fostering an innovative mindset across the organization. Effective executive coaching ensures that leaders are well-equipped to navigate the complexities of integrating new technologies and achieving business success.

Effective Communication for Organizational Success

Effective communication is a cornerstone of successful technological integration in mineral processing. Clear and consistent communication helps align all team members with the organization’s strategic goals and ensures that everyone understands the benefits and requirements of new technologies. In fast-paced business environments like those in Saudi Arabia and UAE, effective communication is essential for maintaining operational efficiency and achieving business objectives. By fostering open communication channels, mining companies can build trust, encourage collaboration, and drive continuous improvement. This approach not only enhances technological adoption but also contributes to a positive organizational culture and improved employee engagement.

Generative AI for Predictive Maintenance

Generative AI is revolutionizing predictive maintenance in the mining sector. By analyzing historical data and generating predictive models, Generative AI can identify potential equipment failures before they occur, allowing for timely maintenance and minimizing downtime. This technology provides actionable insights that enable mining companies to optimize maintenance schedules, reduce costs, and enhance the reliability of their operations. In technologically advanced regions like Saudi Arabia and UAE, adopting Generative AI for predictive maintenance aligns with the goals of operational excellence and sustainability.

In conclusion, advances in flotation technology, including the use of collectors, frothers, and modifiers, significantly enhance the efficiency and effectiveness of mineral separation in complex ore bodies. By integrating these technologies with AI, blockchain, and the Metaverse, mining companies in Saudi Arabia, UAE, Riyadh, and Dubai can achieve greater operational efficiency and business success. Effective change management, executive coaching, and communication are crucial for the successful adoption of these technologies, positioning mining companies at the forefront of innovation and sustainability in the industry.

#FlotationTechnology #MineralProcessing #Innovation #GravityConcentration #MagneticSeparation #SaudiArabia #UAE #Riyadh #Dubai #ChangeManagement #ExecutiveCoaching #EffectiveCommunication #BusinessSuccess #ManagementConsulting #AI #Blockchain #TheMetaverse #GenerativeAI #LeadershipSkills #ProjectManagement