The Role of Real-Time Analytics in IoT-Based Predictive Maintenance

Improving Decision-Making with Real-Time Data

The integration of real-time analytics in IoT-based predictive maintenance is revolutionizing how businesses in Saudi Arabia, UAE, Riyadh, and Dubai approach equipment maintenance. By utilizing real-time data, companies can make informed decisions that prevent equipment failures, reduce downtime, and optimize operational efficiency. The ability to process and analyze data as it is generated allows maintenance teams to identify potential issues before they escalate, ensuring that corrective actions are taken promptly. This proactive approach not only extends the lifespan of critical assets but also minimizes the costly interruptions that can result from unexpected equipment failures. For business executives and project managers in fast-paced environments, the implementation of real-time analytics is a key driver of operational success and competitive advantage.

Enhancing Predictive Models with Continuous Data Streams

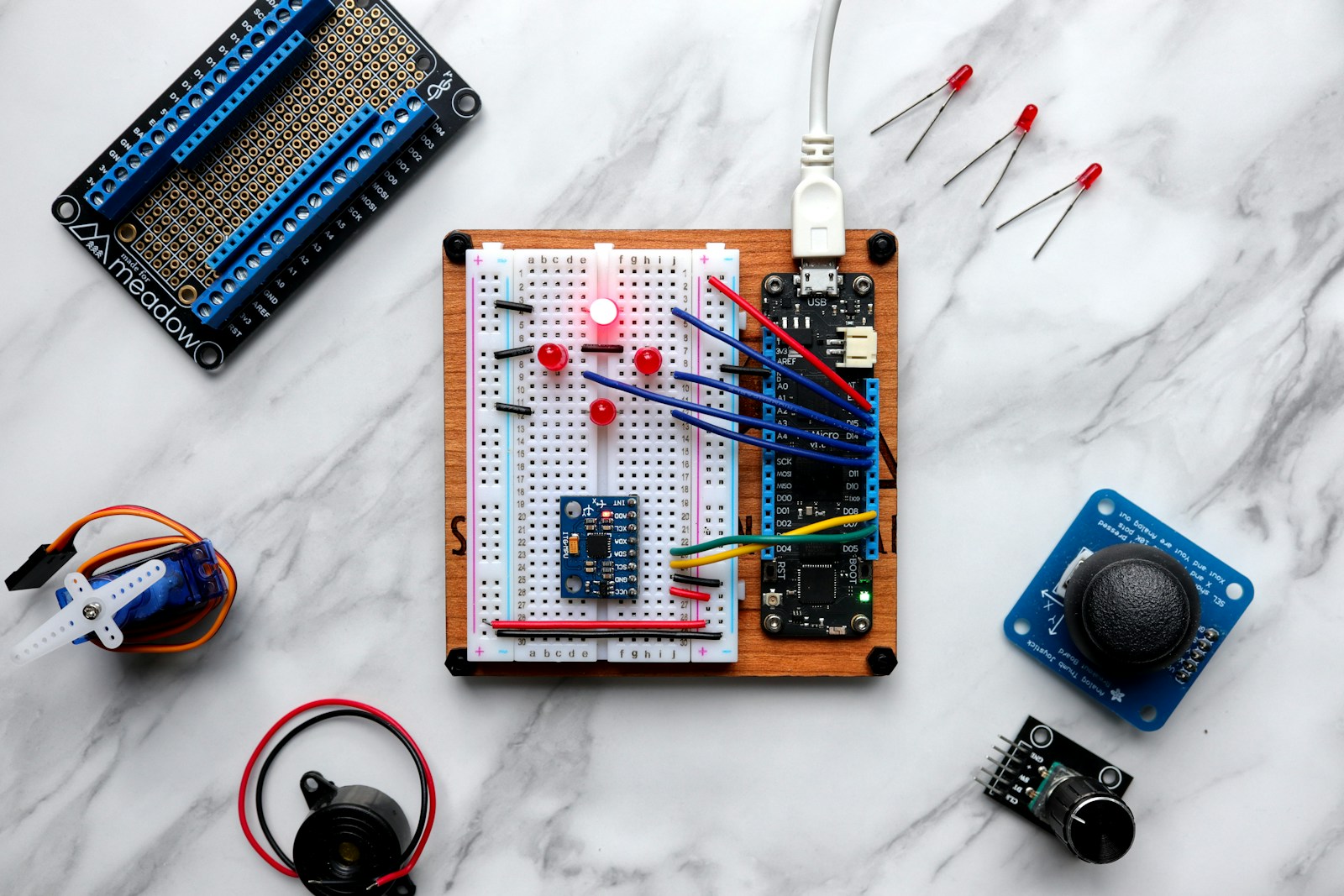

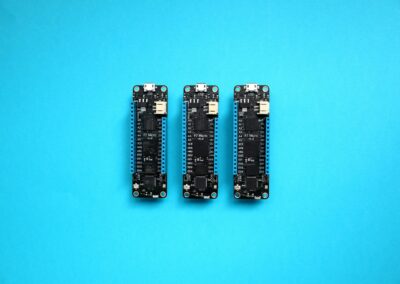

One of the primary benefits of employing real-time analytics in IoT-based predictive maintenance is the ability to continuously enhance predictive models. As IoT devices collect vast amounts of data from machinery and equipment, real-time analytics enable the continuous refinement of predictive algorithms. This iterative process ensures that the models remain accurate and effective in predicting equipment failures and maintenance needs. In regions like Riyadh and Dubai, where industrial operations and infrastructure projects are expanding rapidly, the ability to rely on accurate predictive models is crucial for maintaining efficiency and minimizing operational risks. Real-time analytics provide the necessary feedback loop to keep these models up-to-date, allowing businesses to stay ahead of potential maintenance challenges.

Reducing Maintenance Costs and Downtime

The deployment of real-time analytics in IoT-based predictive maintenance also plays a significant role in reducing maintenance costs and downtime. By accurately predicting when and where maintenance is needed, companies can schedule maintenance activities during planned downtimes, avoiding costly unplanned outages. This level of precision not only reduces the overall maintenance costs but also enhances the productivity of the workforce by ensuring that resources are allocated efficiently. For businesses in Saudi Arabia and the UAE, where operational efficiency is paramount, the ability to minimize downtime through predictive maintenance is a key factor in sustaining growth and profitability. Real-time analytics empower companies to optimize their maintenance strategies, leading to more efficient and cost-effective operations.

Strategic Benefits of Real-Time Analytics in IoT-Driven Maintenance

Optimizing Asset Utilization with Predictive Insights

The strategic benefits of integrating real-time analytics in IoT-based predictive maintenance extend beyond cost savings and downtime reduction; they also include optimizing asset utilization. By providing insights into the actual performance and condition of equipment, real-time analytics enable businesses to maximize the utilization of their assets. This means that machinery can be used more efficiently, with maintenance scheduled at optimal times to avoid unnecessary wear and tear. For companies operating in the competitive markets of Riyadh and Dubai, where asset utilization directly impacts profitability, the ability to optimize the use of critical assets is a significant advantage. Real-time analytics provide the necessary data to make informed decisions about asset management, ensuring that equipment is used to its fullest potential while minimizing the risk of failure.

Enhancing Customer Satisfaction through Reliable Operations

Another critical advantage of using real-time analytics in IoT-based predictive maintenance is the enhancement of customer satisfaction. Reliable operations are essential for maintaining customer trust and delivering consistent service. By preventing unexpected equipment failures and ensuring that maintenance is performed when needed, businesses can maintain a high level of operational reliability. This reliability translates into better customer experiences, as services and products are delivered on time and without disruption. In the highly competitive markets of Saudi Arabia and the UAE, where customer expectations are high, the ability to maintain reliable operations through predictive maintenance is crucial for business success. Real-time analytics play a pivotal role in achieving this reliability, helping companies build and maintain strong customer relationships.

Supporting Long-Term Business Growth with Predictive Maintenance

Finally, the adoption of real-time analytics in IoT-based predictive maintenance supports long-term business growth by ensuring that operations are efficient, reliable, and cost-effective. As businesses in Riyadh, Dubai, and across the GCC region continue to expand, the need for scalable and sustainable maintenance solutions becomes increasingly important. Real-time analytics provide the tools necessary to scale predictive maintenance strategies in line with business growth, ensuring that operations remain efficient as they expand. This scalability is essential for companies looking to maintain their competitive edge in a rapidly evolving market. By investing in real-time analytics and IoT-based predictive maintenance, businesses can position themselves for long-term success, driving growth and innovation in their industries.

—

#PredictiveMaintenance, #RealTimeAnalytics, #IoTTechnology, #BusinessTechnology, #ModernTechnology, #ProjectManagement, #SaudiArabia, #UAE, #Riyadh, #Dubai