Optimizing Product Inspection Through Machine Vision Technology

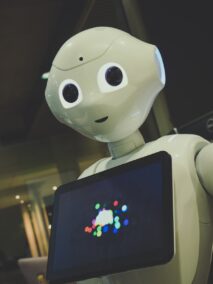

Introduction to Machine Vision Inspection

Machine vision inspection is revolutionizing quality control processes by enabling robots to identify and address product defects with precision and efficiency. In Saudi Arabia and the UAE, where industries are striving to maintain high standards of quality and compliance, machine vision offers a reliable solution for inspecting products across various sectors, including manufacturing, automotive, and electronics. By leveraging advanced imaging technologies and Artificial Intelligence algorithms, machine vision systems can detect defects, anomalies, and deviations from specifications, ensuring that only products of the highest quality reach the market.

The integration of machine vision inspection systems in Riyadh and Dubai reflects a commitment to excellence and continuous improvement in manufacturing practices. By automating the inspection process, companies can minimize human error, increase throughput, and reduce the risk of defects escaping detection. Moreover, machine vision enables real-time monitoring and analysis of production lines, allowing for proactive intervention and adjustment to prevent quality issues before they occur. This proactive approach not only enhances product quality but also reduces waste and rework, leading to cost savings and improved efficiency.

Furthermore, machine vision inspection systems offer valuable data insights that can drive process optimization and innovation. By analyzing images and performance metrics, manufacturers can identify trends, patterns, and areas for improvement in their production processes. This data-driven approach enables companies to optimize parameters, refine workflows, and enhance overall quality control strategies. Additionally, machine vision technology facilitates compliance with regulatory requirements and industry standards, ensuring that products meet customer expectations and regulatory mandates.

The Role of Artificial Intelligence in Machine Vision

Artificial Intelligence (AI) plays a crucial role in enhancing the capabilities and performance of machine vision inspection systems. In Saudi Arabia and the UAE, where industries are embracing digital transformation, AI-driven algorithms enable machines to interpret complex visual data and make decisions in real-time. By training machine learning models on vast datasets of images, AI can identify subtle defects and variations that may be imperceptible to the human eye, ensuring thorough and accurate inspection results.

Moreover, AI-powered machine vision systems offer adaptive learning capabilities, allowing them to continuously improve and adapt to changing production environments and product specifications. Through feedback loops and iterative learning processes, AI algorithms can refine their performance over time, enhancing accuracy and reducing false positives. This adaptive approach not only improves the reliability of inspection results but also minimizes the need for manual intervention and reprogramming, saving time and resources for manufacturers.

Additionally, AI-driven machine vision inspection systems enable predictive maintenance and quality forecasting, helping manufacturers anticipate potential issues and take proactive measures to prevent downtime and defects. By analyzing historical data and performance trends, AI algorithms can identify early warning signs of equipment failure or process deviations, enabling timely interventions to maintain production uptime and product quality. This predictive capability not only enhances operational efficiency but also reduces costs associated with unplanned maintenance and product recalls.

Driving Business Success Through Machine Vision

Machine vision inspection technology offers numerous benefits for businesses in Saudi Arabia, the UAE, and beyond, including improved product quality, operational efficiency, and customer satisfaction. By investing in machine vision systems, companies can enhance their competitive advantage, differentiate their products in the market, and build trust with customers by delivering consistently high-quality products. Moreover, machine vision enables manufacturers to meet stringent quality standards and regulatory requirements, opening up opportunities for market expansion and growth.

Furthermore, machine vision inspection systems contribute to sustainability and resource efficiency by minimizing waste, reducing rework, and optimizing production processes. By identifying defects early in the manufacturing process, companies can minimize scrap, conserve raw materials, and reduce their environmental footprint. This commitment to sustainability not only aligns with corporate social responsibility initiatives but also resonates with environmentally conscious consumers who prioritize ethical and sustainable products.

In conclusion, machine vision inspection technology is transforming quality control processes in Saudi Arabia and the UAE, offering advanced capabilities for detecting defects and ensuring product integrity. By leveraging machine vision systems equipped with Artificial Intelligence, businesses can enhance their competitiveness, streamline operations, and drive business success in a rapidly evolving marketplace. Through strategic investment in machine vision technology and a commitment to continuous improvement, companies can achieve new levels of quality, efficiency, and innovation in their manufacturing operations.

#machinevision #inspection #qualitycontrol #technology #manufacturing #SaudiArabia #UAE #Riyadh #Dubai #changemanagement #executivecoaching #effectivecommunication #businesssuccess #managementconsulting #ArtificialIntelligence #Blockchain #TheMetaverse #GenerativeArtificialIntelligence #leadership #projectmanagement