The Next Generation of Autonomous Manufacturing: AI and Robotics in Saudi Arabia and the UAE

Future Trends in AI and Robotics for Autonomous Manufacturing

In the rapidly evolving landscape of industrial automation, future trends in AI and robotics for autonomous manufacturing are poised to revolutionize the way factories operate, particularly in dynamic regions like Saudi Arabia and the UAE. As businesses in these countries continue to invest in cutting-edge technologies, the integration of AI and robotics into manufacturing processes is set to enhance efficiency, precision, and overall business success. The next generation of autonomous manufacturing systems will be characterized by the ability to operate with minimal human intervention, driven by advances in Artificial Intelligence, machine learning, and robotics. These technologies will enable factories to adapt quickly to changing market demands, optimize production workflows, and reduce operational costs.

One of the most significant trends shaping the future of autonomous manufacturing is the development of smart factories, where AI-powered robots and machines communicate and collaborate in real-time. These smart factories leverage advanced sensors, IoT devices, and AI algorithms to monitor and analyze production processes, making real-time adjustments to optimize efficiency. In markets like Riyadh and Dubai, where industries are rapidly modernizing, the adoption of smart factory technology is expected to drive significant improvements in productivity and competitiveness. For instance, AI-driven predictive maintenance systems can anticipate equipment failures before they occur, reducing downtime and extending the lifespan of machinery, which is particularly valuable in regions where operational efficiency is paramount.

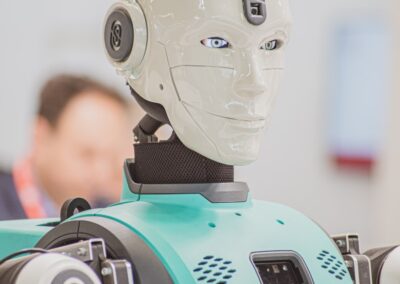

Another key trend is the increasing use of collaborative robots, or cobots, which work alongside human operators to enhance productivity and safety. Unlike traditional industrial robots, cobots are designed to be more flexible and easier to program, making them ideal for small and medium-sized enterprises (SMEs) in Saudi Arabia and the UAE. These robots can perform repetitive tasks with high precision, allowing human workers to focus on more complex and value-added activities. The integration of AI into cobots enables them to learn from their interactions and improve their performance over time, leading to more efficient and adaptive manufacturing processes. As businesses in these regions continue to adopt cobot technology, they can expect to see significant gains in both productivity and workforce satisfaction.

The Impact of AI and Robotics on Business Success in Manufacturing

The implementation of AI and robotics in autonomous manufacturing is expected to have a profound impact on business success, particularly in the highly competitive markets of Saudi Arabia and the UAE. As industries in these regions continue to embrace digital transformation, the ability to leverage AI and robotics will be a key differentiator in achieving operational excellence and maintaining a competitive edge. One of the most notable benefits of AI-driven manufacturing systems is their ability to process and analyze vast amounts of data in real-time, enabling businesses to make more informed decisions and optimize their operations. This level of data-driven decision-making is essential for companies aiming to remain agile and responsive to market changes.

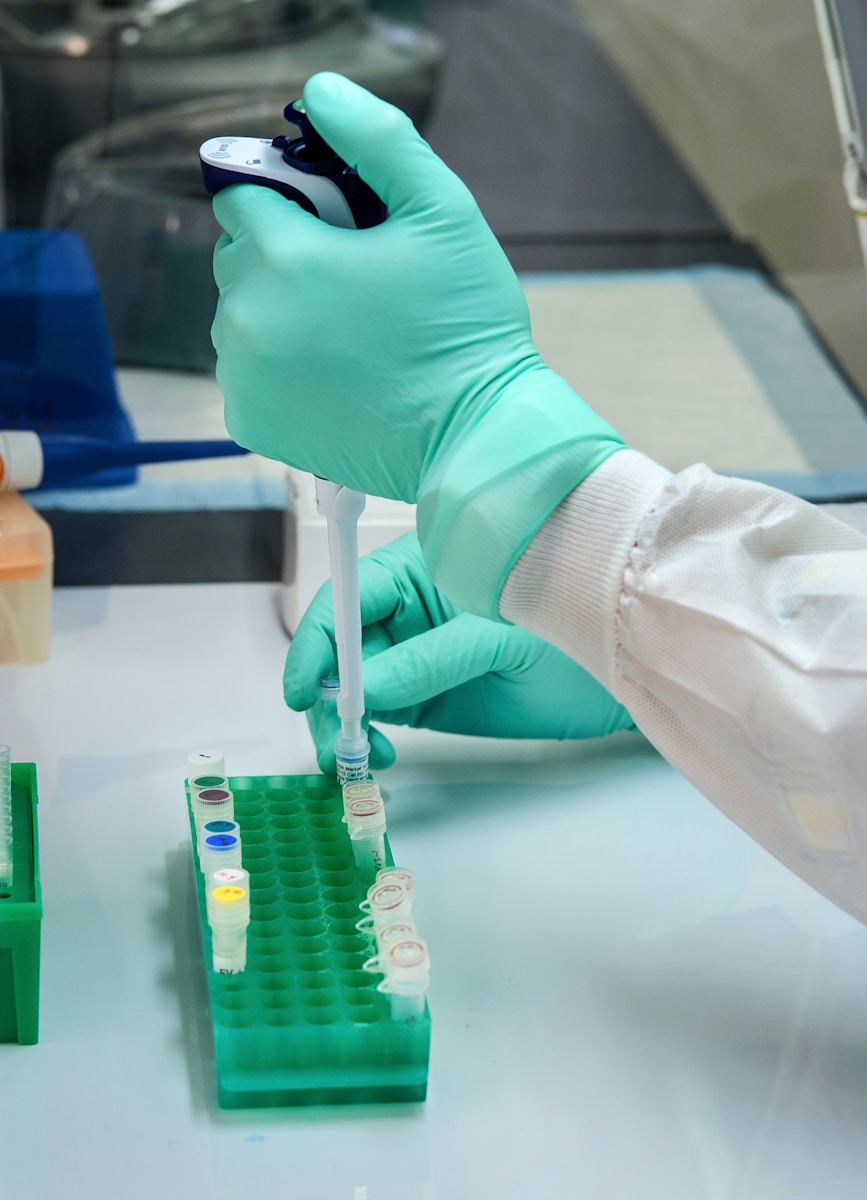

In addition to enhancing operational efficiency, AI and robotics also play a crucial role in improving product quality and consistency. By automating complex and precise manufacturing processes, businesses can reduce the risk of human error and ensure that products meet the highest standards of quality. This is particularly important in industries such as automotive, aerospace, and electronics, where even minor defects can have significant consequences. In the context of management consulting and executive coaching, understanding the impact of AI and robotics on product quality is essential for guiding businesses through the complexities of technology adoption and helping them achieve their strategic goals.

Furthermore, the integration of AI and robotics into manufacturing processes also has implications for workforce management and development. As autonomous systems take on more routine tasks, there is a growing need for skilled workers who can manage and maintain these advanced technologies. In Saudi Arabia and the UAE, where there is a strong emphasis on developing local talent, businesses must invest in training and development programs to equip their workforce with the necessary skills to thrive in an AI-driven manufacturing environment. This includes providing opportunities for upskilling and reskilling, as well as fostering a culture of continuous learning and innovation. By prioritizing leadership and management skills, businesses can ensure that their teams are prepared to navigate the challenges and opportunities presented by the future of autonomous manufacturing.

#FutureTrends #AIinManufacturing #Robotics #AutonomousSystems #BusinessSuccess #SaudiArabia #UAE #ChangeManagement #ExecutiveCoaching #LeadershipSkills