Revolutionizing Construction, Healthcare, and Manufacturing with 3D Printing

The Transformative Impact of 3D Printing in Construction

The construction industry has witnessed significant advancements with the introduction of 3D printing technologies. In regions like Saudi Arabia, UAE, Riyadh, and Dubai, where rapid urban development is a priority, 3D printing offers innovative solutions to traditional construction challenges. By enabling the creation of complex structures with precision and efficiency, 3D printing has the potential to revolutionize the construction landscape.

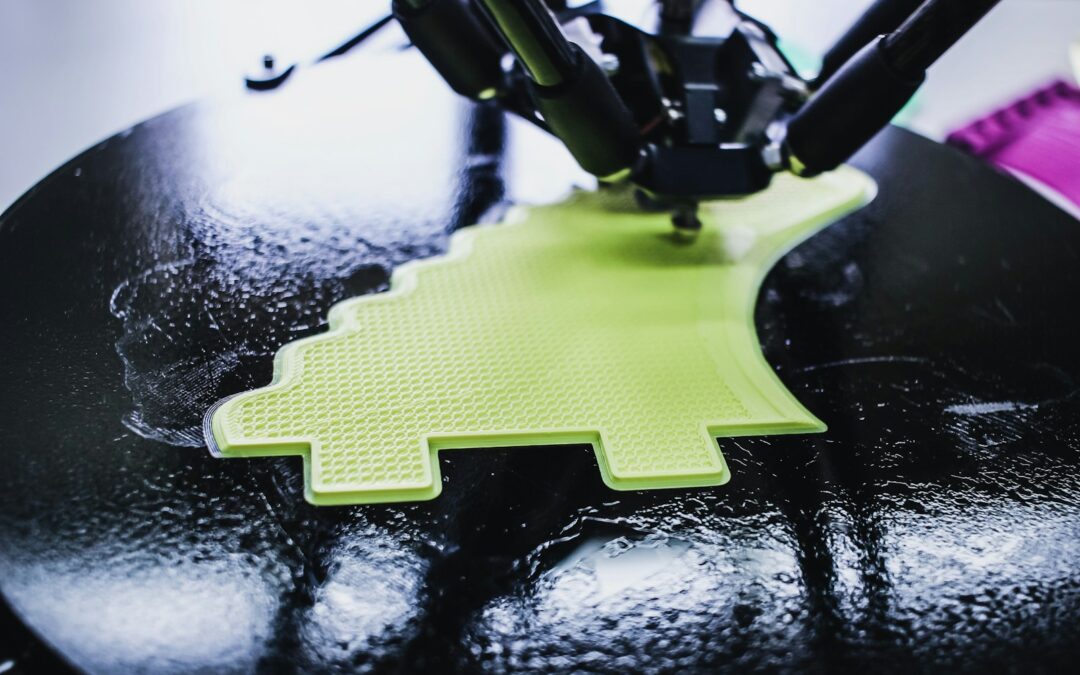

One of the key benefits of 3D printing in construction is the reduction of material waste. Traditional construction methods often result in significant waste due to the cutting and shaping of materials. However, 3D printing allows for the precise layering of materials, ensuring that only the necessary amount is used. This not only reduces costs but also aligns with sustainable building practices, a crucial consideration in modern construction.

Furthermore, 3D printing can significantly speed up the construction process. By automating the creation of building components, structures can be completed in a fraction of the time compared to traditional methods. This rapid construction capability is particularly beneficial in regions with ambitious development goals, such as Saudi Arabia’s Vision 2030, which aims to diversify the economy and reduce dependence on oil through large-scale infrastructure projects.

Enhancing Healthcare with 3D Printing Technologies

The healthcare industry stands to gain immensely from the adoption of 3D printing technologies. In advanced medical hubs like Riyadh and Dubai, 3D printing is being used to create customized medical devices, prosthetics, and even bioprinted tissues. This technology enables the production of patient-specific solutions, enhancing the effectiveness and comfort of medical treatments.

Custom prosthetics and implants are one of the most significant applications of 3D printing in healthcare. Traditional prosthetics often require extensive customization and adjustments to fit the patient properly. With 3D printing, prosthetics can be tailored to the exact specifications of the patient, improving comfort and functionality. This is particularly important in regions with growing healthcare demands, where efficient and effective medical solutions are essential.

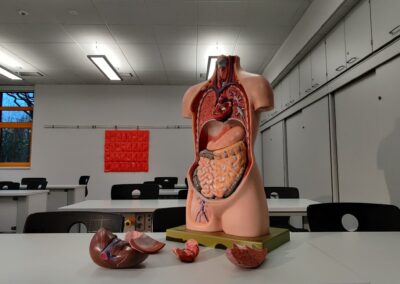

Moreover, 3D printing is revolutionizing surgical procedures through the creation of patient-specific anatomical models. Surgeons can use these models to plan and practice complex surgeries, reducing the risk of complications and improving patient outcomes. In medical centers across the UAE and Saudi Arabia, such innovations are enhancing the quality of care and positioning these regions as leaders in medical technology.

Transforming Manufacturing with 3D Printing

Manufacturing is another industry that is experiencing a profound transformation due to 3D printing technologies. The ability to produce complex and customized components with precision and efficiency is redefining manufacturing processes in Riyadh, Dubai, and beyond. This shift is not only improving production capabilities but also driving innovation and competitiveness.

One of the most significant advantages of 3D printing in manufacturing is its ability to facilitate rapid prototyping. Traditional prototyping methods can be time-consuming and costly, often requiring the creation of molds and tooling. 3D printing eliminates these steps, allowing manufacturers to quickly produce and test prototypes. This accelerates the development process and enables companies to bring products to market faster.

Additionally, 3D printing supports the concept of decentralized manufacturing. Instead of relying on centralized factories, components can be printed on-demand at various locations, reducing logistics costs and lead times. This flexibility is particularly valuable in the dynamic business environments of Saudi Arabia and the UAE, where agility and responsiveness are critical to success.

Integrating 3D Printing into Business Strategy

Adopting 3D Printing for Competitive Advantage

For business executives and entrepreneurs, integrating 3D printing into their strategic plans can offer a significant competitive advantage. The ability to innovate and adapt quickly is crucial in today’s fast-paced markets, and 3D printing provides the tools to do just that. By leveraging this technology, businesses in Riyadh, Dubai, and other major hubs can enhance their product offerings and streamline their operations.

Executive coaching services can play a pivotal role in guiding leaders through the adoption of 3D printing technologies. Coaches can help executives understand the potential applications and benefits of 3D printing, as well as the challenges involved in its implementation. By providing strategic insights and fostering a culture of innovation, executive coaches can support leaders in making informed decisions that drive business success.

Furthermore, integrating 3D printing into business strategies aligns with the broader goals of economic diversification and technological advancement in regions like Saudi Arabia and the UAE. By embracing cutting-edge technologies, businesses can contribute to the development of a knowledge-based economy, positioning these regions as global leaders in innovation and technology.

Overcoming Challenges in 3D Printing Adoption

While the benefits of 3D printing are clear, businesses must also navigate several challenges to fully realize its potential. One of the primary obstacles is the initial investment required for 3D printing equipment and training. For mid-level managers and entrepreneurs, understanding the long-term ROI and developing a clear implementation plan is essential to justify this investment.

Another challenge is the integration of 3D printing with existing manufacturing and operational processes. Businesses need to assess how 3D printing will fit into their current workflows and identify any adjustments needed to optimize efficiency. This may involve rethinking supply chains, retraining staff, and updating quality control measures to accommodate the new technology.

Intellectual property (IP) considerations also play a critical role in 3D printing adoption. The ability to easily replicate designs raises concerns about IP protection and the potential for counterfeit products. Businesses must develop robust IP strategies to safeguard their innovations while leveraging the benefits of 3D printing. This includes understanding the legal landscape and implementing measures to protect proprietary designs and processes.

Conclusion: Embracing the Future with 3D Printing Technologies

The potential applications of 3D printing technologies in industries such as construction, healthcare, and manufacturing are vast and transformative. For business executives, mid-level managers, and entrepreneurs in Saudi Arabia, UAE, Riyadh, and Dubai, embracing these technologies offers significant opportunities for innovation, efficiency, and competitiveness.

By adopting 3D printing, businesses can enhance their capabilities, streamline operations, and contribute to the broader goals of technological advancement and economic diversification in their regions. Executive coaching services can support leaders in navigating the complexities of 3D printing adoption, ensuring that they make informed decisions that drive long-term success.

As 3D printing continues to evolve, its impact on industries will only grow, reshaping how we build, heal, and manufacture. By staying at the forefront of this technological revolution, businesses can position themselves as leaders in innovation, driving progress and success in the modern economy.

—

#3DPrintingTechnologies #Construction3DPrinting #Healthcare3DPrinting #Manufacturing3DPrinting #SaudiArabiaTechnology #UAETechnology #RiyadhInnovation #Dubai3DPrinting #ArtificialIntelligence #ExecutiveCoaching #GenerativeAI #ModernTechnology #BusinessSuccess #LeadershipSkills #ProjectManagement