Transforming Industries with IoT-Driven Automation

The Role of IoT in Industrial Automation

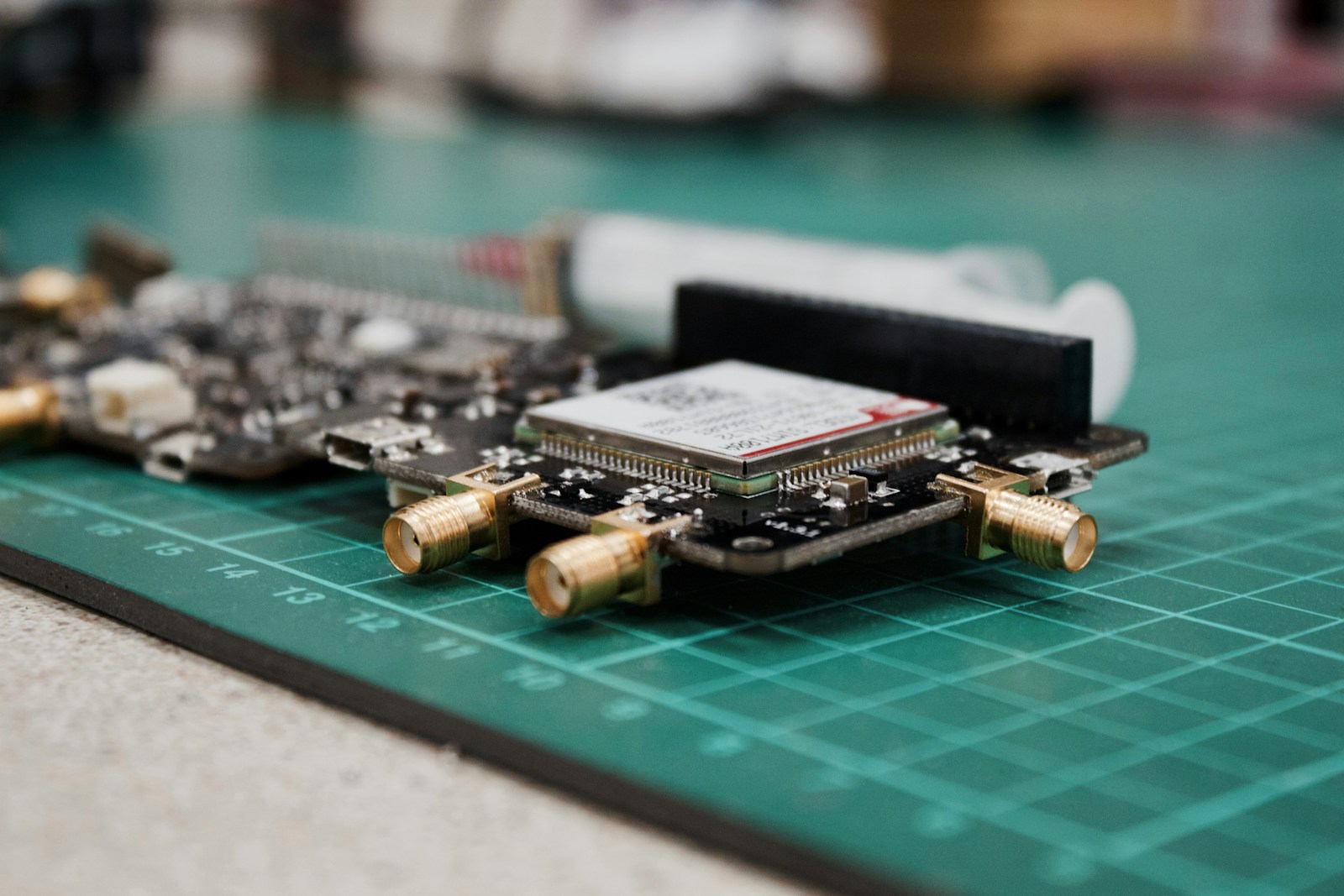

IoT in industrial automation is revolutionizing the way industries operate by enhancing efficiency and driving innovation. In Saudi Arabia and the UAE, the adoption of IoT technology is a key component of the broader digital transformation strategies aimed at boosting economic growth and competitiveness. By integrating IoT sensors and devices into industrial processes, businesses can achieve real-time monitoring, predictive maintenance, and automated decision-making. This results in improved operational efficiency, reduced downtime, and significant cost savings, making IoT in industrial automation a critical driver of success in modern manufacturing.

The impact of IoT in industrial automation extends beyond just operational efficiency; it fosters a culture of innovation. By providing access to real-time data and analytics, IoT enables industries to identify areas for improvement and implement innovative solutions that enhance productivity. For example, smart factories equipped with IoT devices can dynamically adjust production lines based on demand fluctuations, optimizing resource utilization and minimizing waste. This level of agility is particularly valuable in industries such as oil and gas, petrochemicals, and manufacturing, which are central to the economies of Riyadh and Dubai.

Leveraging Predictive Maintenance for Enhanced Efficiency

Predictive maintenance is one of the most promising applications of IoT in industrial automation. By using IoT sensors to monitor the condition of machinery and equipment, businesses can predict when maintenance is needed, preventing costly breakdowns and extending the lifespan of their assets. In Saudi Arabia and the UAE, where industries operate under harsh environmental conditions, the ability to anticipate equipment failures and perform maintenance proactively is a game-changer. This approach not only reduces downtime but also enhances the safety and reliability of industrial operations.

IoT-driven predictive maintenance relies on advanced analytics and machine learning algorithms to analyze data from sensors and predict potential issues. For instance, by monitoring temperature, vibration, and other key parameters, IoT systems can identify signs of wear and tear before they lead to failures. This predictive capability allows maintenance teams to address problems early, reducing repair costs and minimizing disruptions to production. As IoT technology continues to evolve, predictive maintenance will become even more precise, further enhancing the efficiency and reliability of industrial automation systems.

Smart Supply Chains and IoT Integration

The integration of IoT in industrial automation also extends to supply chain management, where it plays a crucial role in enhancing visibility and optimizing logistics. In smart factories, IoT sensors can track the movement of materials and products throughout the supply chain, providing real-time updates on inventory levels, shipment status, and delivery times. This level of transparency is essential for maintaining efficient supply chains, especially in dynamic markets like Riyadh and Dubai, where timely and accurate information is critical for decision-making.

IoT-enabled supply chains are not only more efficient but also more resilient. By providing real-time data on supply chain performance, IoT allows businesses to identify potential disruptions early and take corrective action. For example, if a shipment is delayed, IoT systems can automatically reroute resources to mitigate the impact on production schedules. This adaptability is key to maintaining competitiveness in an increasingly complex and fast-paced global market. As industries continue to embrace IoT technology, the integration of IoT in supply chain management will play an increasingly important role in driving industrial automation and innovation.

Emerging Trends and Challenges in IoT-Enabled Industrial Automation

AI and Machine Learning in Industrial Automation

Artificial intelligence (AI) and machine learning (ML) are powerful tools that complement IoT in industrial automation, enabling smarter decision-making and process optimization. By analyzing the vast amounts of data generated by IoT devices, AI and ML algorithms can identify patterns, optimize workflows, and predict outcomes with high accuracy. In the industrial sectors of Saudi Arabia and the UAE, where efficiency and innovation are top priorities, the combination of AI and IoT is driving significant advancements in automation.

For instance, AI can optimize energy consumption in smart factories by dynamically adjusting power usage based on production needs, reducing operational costs, and supporting sustainability goals. Machine learning models can also be used to enhance quality control processes, detecting defects in products with greater accuracy than traditional methods. This level of precision and efficiency is essential for industries looking to maintain a competitive edge in the global market. As AI and ML technologies continue to evolve, their integration with IoT in industrial automation will unlock new possibilities for innovation and efficiency.

Blockchain for Secure and Transparent Industrial Processes

Blockchain technology is another emerging trend that, when combined with IoT, enhances the security and transparency of industrial automation processes. Blockchain provides a secure, decentralized ledger for recording transactions and data, ensuring that all actions within the automation system are traceable and verifiable. In regions like Dubai, where blockchain adoption is rapidly advancing, integrating blockchain with IoT can address key challenges such as data security, integrity, and compliance.

For example, blockchain can be used to securely record the maintenance history of industrial equipment, providing a transparent and tamper-proof record that can be accessed by all relevant stakeholders. This is particularly valuable in industries with stringent regulatory requirements, such as pharmaceuticals and aerospace, where compliance with standards is critical. By leveraging blockchain technology, businesses can enhance the trustworthiness of their automation systems, build stronger relationships with partners, and ensure that their operations meet the highest standards of security and integrity.

Addressing Challenges in IoT-Enabled Industrial Automation

Despite the numerous benefits of IoT in industrial automation, there are challenges that businesses must address to fully realize its potential. One of the primary challenges is the complexity of integrating IoT solutions with existing industrial systems. Many industries rely on legacy equipment that may not be compatible with modern IoT devices, necessitating significant investments in upgrades and retrofits. In Riyadh and Dubai, where industrial modernization is a key focus, companies are exploring innovative solutions to bridge the gap between old and new technologies.

Additionally, data security and privacy remain major concerns in IoT-enabled industrial automation. As the number of connected devices increases, so does the risk of cyber-attacks. To mitigate these risks, businesses must implement robust cybersecurity measures, such as encryption, access controls, and continuous monitoring of IoT networks. By prioritizing security and investing in the necessary infrastructure, companies can protect their assets, maintain operational integrity, and build trust with customers and partners.

In conclusion, IoT in industrial automation is set to revolutionize industries by enhancing efficiency, driving innovation, and enabling smarter decision-making. As technologies like AI, machine learning, and blockchain continue to evolve, their integration with IoT will unlock new opportunities for industrial growth and transformation. For businesses in Saudi Arabia and the UAE, embracing IoT-enabled automation is not just a strategic choice but a necessity for achieving long-term success in a rapidly changing world.

—

#iot #industrialautomation #digitaltransformation #smartfactories #AI #blockchain #predictivemaintenance #SaudiArabia #UAE #smarttechnology