Revolutionizing Manufacturing with Digital Twin Technology

Enhancing Supply Chain Transparency through Digital Twins

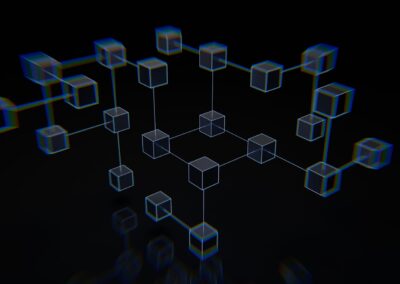

The application of digital twin technology in manufacturing is a transformative development that significantly enhances supply chain transparency. A digital twin is a virtual model of a physical object or system, created by integrating data from various sources. This technology provides an accurate and dynamic representation of manufacturing processes, enabling real-time monitoring and analysis. For business executives, mid-level managers, and entrepreneurs, particularly in regions like Saudi Arabia, the UAE, Riyadh, and Dubai, the benefits of implementing digital twins are profound.

By using digital twins, manufacturers can gain comprehensive visibility into their supply chain operations. This includes tracking the production status of goods, monitoring equipment performance, and analyzing the flow of materials. The real-time data provided by digital twins helps companies identify inefficiencies, detect anomalies, and address issues before they escalate. For instance, if a machine in a production line malfunctions, the digital twin can instantly alert managers, allowing them to take corrective actions promptly. This heightened level of transparency is crucial for maintaining operational efficiency and meeting customer expectations in fast-paced markets.

Furthermore, digital twins enhance transparency by offering a unified view of the entire supply chain. This integration allows companies to see how changes in one part of the supply chain impact other areas. For example, a delay in raw material delivery can affect production schedules and customer delivery times. By visualizing these interdependencies, manufacturers can make more informed decisions, optimize their operations, and improve overall supply chain performance. In dynamic environments like Riyadh and Dubai, where quick and accurate decision-making is essential, digital twins offer a significant competitive advantage.

Improving Supply Chain Agility with Real-Time Insights

In addition to transparency, digital twin technology in manufacturing plays a crucial role in enhancing supply chain agility. Agility refers to a company’s ability to adapt quickly to changes in the market and respond to unforeseen challenges. Digital twins provide manufacturers with real-time insights into their operations, enabling them to make swift adjustments and remain agile in a constantly evolving landscape.

One of the key advantages of digital twins is their ability to simulate various scenarios and predict potential outcomes. This capability allows manufacturers to evaluate different strategies and assess their impact on the supply chain. For instance, if there is a sudden surge in demand for a product, digital twins can model the effects on production capacity, inventory levels, and delivery schedules. By testing different scenarios, companies can identify the most effective response strategies and implement them proactively. This level of agility is particularly valuable in regions like Saudi Arabia and the UAE, where market conditions can change rapidly and unpredictably.

Moreover, digital twins facilitate agile decision-making by providing real-time data on supply chain performance. This data includes information on production rates, equipment utilization, and inventory levels. With access to this information, managers can quickly identify and address issues, such as bottlenecks or supply shortages. By enabling faster and more accurate decision-making, digital twins help manufacturers respond to market changes and operational challenges with greater agility. In cities like Dubai and Riyadh, where efficiency and responsiveness are critical, this agility can be a key differentiator for business success.

Implementing Digital Twin Technology: Challenges and Considerations

While the benefits of digital twin technology in manufacturing are substantial, implementing this technology comes with its own set of challenges. One of the primary considerations is the integration of digital twins with existing manufacturing systems and processes. Companies need to ensure that their infrastructure can support the continuous flow of data required for digital twin operations. This may involve upgrading IoT devices, enhancing data storage capabilities, and investing in advanced analytics platforms.

Additionally, successful implementation of digital twins requires a clear understanding of the specific needs and goals of the manufacturing process. Business executives and managers must work closely with technology providers to tailor digital twin solutions to their unique requirements. This collaborative approach ensures that the technology delivers maximum value and aligns with the overall strategic objectives of the company. In regions like Saudi Arabia and the UAE, where technological innovation is a driving force, businesses that effectively leverage digital twins can position themselves as industry leaders.

Training and development are also essential for the successful adoption of digital twins. Employees at all levels need to be equipped with the necessary skills to operate and interpret digital twin data effectively. This includes understanding how to use real-time insights, perform scenario simulations, and make data-driven decisions. By investing in training programs, companies can ensure that their workforce is prepared to harness the full potential of digital twins and drive continuous improvement in supply chain performance.

Conclusion: Embracing the Future of Manufacturing

In conclusion, digital twin technology in manufacturing represents a powerful tool for enhancing supply chain transparency and agility. By providing real-time visibility and predictive insights, digital twins enable manufacturers to optimize their operations, respond to market changes, and achieve greater efficiency. For business leaders and entrepreneurs in Saudi Arabia, the UAE, Riyadh, and Dubai, adopting digital twins offers a pathway to staying competitive in a rapidly evolving market.

As technology continues to advance, the applications of digital twins will expand, offering even greater opportunities for innovation and improvement. For businesses that prioritize technological adoption and continuous enhancement, digital twins can serve as a critical asset in navigating the complexities of modern manufacturing and achieving long-term success.

—

#DigitalTwinTechnology, #Manufacturing, #SupplyChainTransparency, #SupplyChainAgility, #SaudiArabia, #UAE, #Riyadh, #Dubai, #ArtificialIntelligence, #ModernTechnology, #BusinessSuccess, #Leadership, #ProjectManagement