Revolutionizing Supply Chain Management with IoT Technology

The Role of IoT-Based Supply Chain Optimization in Addressing Bottlenecks

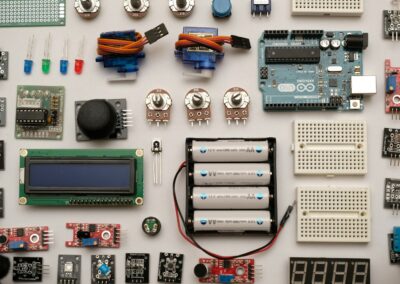

The implementation of IoT-Based Supply Chain Optimization is becoming a critical strategy for businesses seeking to identify and address bottlenecks within their supply chains. In fast-paced markets such as Saudi Arabia and the UAE, where cities like Riyadh and Dubai serve as major commercial hubs, supply chain efficiency is paramount. IoT technology enables real-time data collection from various points in the supply chain, providing businesses with actionable insights into areas of inefficiency. By continuously monitoring the movement of goods, inventory levels, and production timelines, IoT-based systems can detect disruptions and delays that may cause bottlenecks, allowing companies to address these issues proactively.

This continuous flow of data offers a dynamic view of the supply chain, making it easier to identify recurring patterns that could indicate underlying inefficiencies. For instance, if a particular segment of the supply chain consistently experiences delays, IoT sensors can provide data that reveals the root causes, whether it be equipment malfunctions, logistical errors, or supplier inconsistencies. Addressing these bottlenecks not only streamlines operations but also improves overall supply chain resilience, enabling companies to better meet customer demands and maintain a competitive edge in the market.

Enhancing Supply Chain Visibility with Real-Time Data

One of the most significant benefits of IoT-based supply chain optimization is the enhanced visibility it provides. Traditional supply chain management often relies on periodic reports and manual tracking, which can lead to outdated or incomplete information. In contrast, IoT technology offers real-time visibility into every aspect of the supply chain, from the sourcing of raw materials to the delivery of finished products. This level of transparency is particularly valuable in regions like Dubai and Riyadh, where supply chains are complex and involve multiple stakeholders.

Real-time data from IoT-enabled devices allows supply chain managers to monitor the status of shipments, track inventory levels, and ensure that production processes are running smoothly. This information can be used to make informed decisions that prevent bottlenecks before they occur. For example, if IoT sensors detect that a particular supplier is consistently late in delivering materials, a company can take steps to either address the issue with the supplier or find an alternative source. This proactive approach to supply chain management reduces the risk of delays and ensures that operations remain on schedule.

Supporting Continuous Improvement with IoT Analytics

IoT-based supply chain optimization also supports continuous improvement by providing detailed analytics that can be used to refine processes over time. By analyzing the data collected through IoT devices, companies can identify trends and patterns that may not be immediately apparent. These insights can then be used to implement targeted improvements that enhance the efficiency and reliability of the supply chain.

In competitive markets like the UAE and Saudi Arabia, where companies are constantly seeking ways to improve their operations, the ability to leverage IoT analytics for continuous improvement is a significant advantage. For instance, if data analysis reveals that certain transportation routes are consistently slower than others, a company can explore alternative routes or transportation methods to optimize delivery times. Similarly, if IoT data shows that certain equipment is prone to frequent breakdowns, maintenance schedules can be adjusted to prevent unplanned downtime. By continuously refining their supply chain processes, companies can achieve higher levels of efficiency, reduce costs, and improve customer satisfaction.

Strategic Benefits of IoT-Driven Supply Chain Optimization

Reducing Operational Costs and Enhancing Efficiency

The strategic implementation of IoT-driven supply chain optimization offers numerous benefits, particularly in reducing operational costs and enhancing efficiency. By enabling real-time monitoring and data-driven decision-making, IoT technology allows companies to identify inefficiencies and address them before they escalate into major issues. In regions like Saudi Arabia, where operational efficiency is a key differentiator, the cost savings achieved through optimized supply chain management can significantly impact a company’s profitability.

Moreover, IoT technology facilitates more accurate forecasting and demand planning. By analyzing data on consumer behavior, market trends, and inventory levels, companies can better predict demand and adjust their supply chain operations accordingly. This not only reduces the risk of overproduction or stockouts but also minimizes waste and maximizes resource utilization.

Enhancing Customer Satisfaction and Competitive Advantage

IoT-based supply chain optimization also plays a crucial role in enhancing customer satisfaction and maintaining a competitive advantage. In today’s fast-paced market, customers expect timely deliveries and high-quality products. By optimizing their supply chains, companies can ensure that they meet these expectations consistently. IoT technology allows for greater precision in managing inventory levels, reducing the likelihood of stockouts or delays that could negatively impact customer satisfaction.

In highly competitive markets like Dubai, where customer loyalty is often determined by the ability to meet delivery promises, the reliability provided by IoT-driven supply chain optimization is invaluable. Companies that can consistently deliver on time and meet customer expectations are more likely to retain their customers and attract new ones, thereby strengthening their position in the market.

Conclusion: The Future of Supply Chain Management with IoT

In conclusion, the adoption of IoT-Based Supply Chain Optimization is transforming the way companies manage their supply chains, offering enhanced visibility, efficiency, and reliability. By leveraging real-time data and advanced analytics, businesses in Saudi Arabia, the UAE, and beyond can identify and address bottlenecks, reduce operational costs, and continuously improve their processes. As IoT technology continues to evolve, its role in supply chain management will become increasingly central to achieving operational excellence and maintaining a competitive advantage in a rapidly changing global market. Companies that invest in IoT-driven supply chain optimization will be well-positioned to thrive in the future of smart manufacturing and logistics.

—

#IoTSupplyChain #SupplyChainManagement #ContinuousImprovement #SmartTechnology #BusinessInnovation #OperationalEfficiency #IoTAnalytics