Maximizing Productivity with IoT-Enabled Automation Solutions in Industrial Firms

Introduction to IoT-Enabled Automation in Industry

IoT-enabled automation solutions for higher productivity in industrial firms are transforming the way businesses operate, particularly in competitive markets like Saudi Arabia and the UAE. By integrating IoT devices, sensors, and AI-driven analytics, industrial firms can automate complex processes, reduce manual interventions, and achieve unprecedented levels of efficiency. This technological evolution not only enhances productivity but also enables firms to respond more dynamically to market demands, ensuring sustained growth and competitiveness.

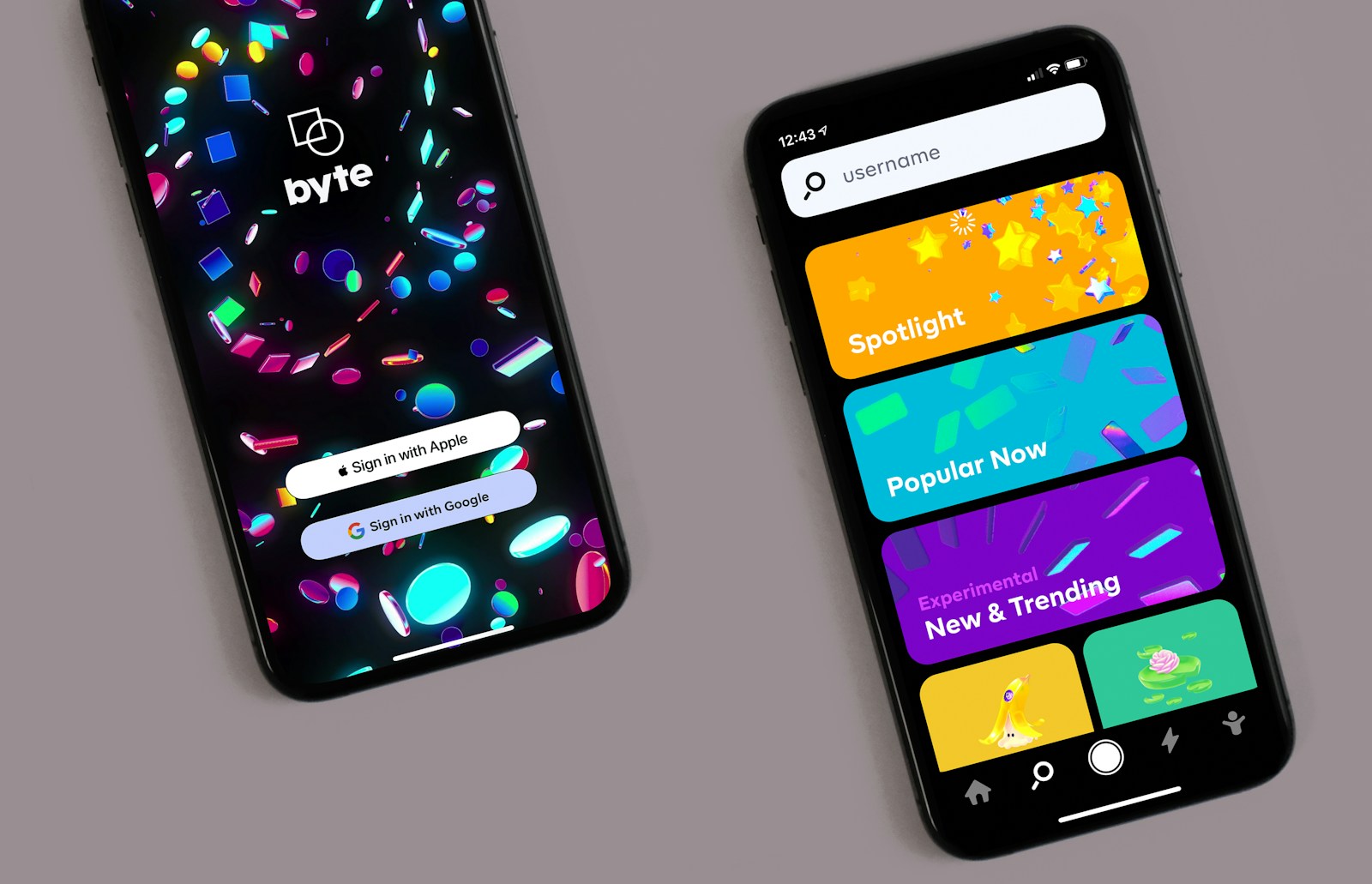

In Dubai, leading industrial firms have successfully implemented IoT-enabled automation solutions for higher productivity. These solutions involve the deployment of smart sensors and connected devices that continuously monitor machinery performance, production processes, and environmental conditions. By collecting and analyzing data in real time, these systems can automatically adjust operations to optimize efficiency, reduce waste, and prevent equipment downtime. For example, automated control systems in manufacturing plants can regulate temperature, pressure, and other critical parameters without human intervention, ensuring consistent product quality and operational stability.

Riyadh’s industrial sector, as part of Saudi Arabia’s Vision 2030, is also embracing IoT-enabled automation to enhance productivity and competitiveness. By leveraging IoT technology, firms in Riyadh are optimizing their production lines, improving asset utilization, and minimizing downtime through predictive maintenance. The success of these initiatives demonstrates the strategic value of IoT-enabled automation in driving industrial growth and achieving national economic goals.

Enhancing Operational Efficiency Through Real-Time Data Analytics

A significant advantage of IoT-enabled automation solutions in industrial firms is the ability to enhance operational efficiency through real-time data analytics. Traditional industrial operations often suffer from inefficiencies due to manual monitoring, delayed responses to equipment issues, and reliance on scheduled maintenance. IoT technology addresses these challenges by providing continuous, real-time insights into every aspect of the production process, allowing firms to make informed decisions that optimize performance and reduce costs.

For example, in Dubai, industrial firms use IoT sensors to monitor equipment conditions such as vibration, temperature, and energy consumption. These sensors provide data that is analyzed using AI algorithms to predict potential equipment failures before they occur. By adopting a proactive maintenance approach, firms can schedule repairs during planned downtimes, thereby avoiding unexpected disruptions and maximizing equipment availability. This not only enhances productivity but also extends the lifespan of critical assets, resulting in significant cost savings.

Moreover, IoT-enabled automation solutions for higher productivity in industrial firms extend beyond equipment monitoring to include process optimization. In Riyadh, manufacturers utilize IoT technology to optimize production workflows, reduce bottlenecks, and improve throughput. By analyzing data from connected devices across the production line, firms can identify inefficiencies and implement changes that streamline operations. This data-driven approach ensures that resources are used effectively, reducing waste and improving overall productivity.

Reducing Downtime and Enhancing Asset Utilization

Another key takeaway from implementing IoT-enabled automation solutions in industrial firms is the reduction of downtime and enhancement of asset utilization. Downtime, whether planned or unplanned, can significantly impact productivity and profitability. IoT-enabled automation addresses this challenge by providing predictive maintenance capabilities and real-time monitoring of asset performance, allowing firms to minimize downtime and maximize the utilization of their resources.

In Saudi Arabia, industrial firms are leveraging IoT technology to monitor the health and performance of critical assets such as machinery, conveyors, and robotic systems. IoT sensors provide continuous data on equipment conditions, enabling maintenance teams to detect issues early and perform maintenance before failures occur. This predictive maintenance approach not only reduces the frequency of breakdowns but also optimizes maintenance schedules, ensuring that assets are available when needed and not sitting idle due to unexpected repairs.

Furthermore, IoT-enabled automation solutions for higher productivity in industrial firms support better decision-making regarding asset management and investment. By providing real-time insights into asset performance and utilization rates, IoT technology enables firms to make data-driven decisions about asset purchases, retirements, and upgrades. In Dubai, industrial firms use IoT analytics to assess the return on investment for their equipment, ensuring that their capital is allocated efficiently and aligned with their strategic goals.

Strategic Approaches to Implementing IoT-Enabled Automation Solutions

Developing a Comprehensive IoT Automation Strategy

To fully harness the potential of IoT-enabled automation solutions, industrial firms must develop comprehensive strategies that align with their broader operational and business objectives. For leaders in Saudi Arabia and the UAE, this involves investing in cutting-edge IoT technologies, fostering collaboration between IT and operational teams, and creating a culture that supports digital transformation. A successful IoT automation strategy should begin with a clear assessment of the firm’s operational challenges and the identification of key areas where IoT can deliver the most impact.

One critical aspect of developing an effective IoT automation strategy is ensuring data integration and interoperability. With a diverse range of IoT devices generating vast amounts of data, achieving seamless communication and integration across different platforms is essential for optimizing operations. By adopting standardized protocols and investing in robust data analytics capabilities, industrial firms can ensure that their IoT systems are capable of providing accurate and actionable insights. In Riyadh, efforts to implement interoperable IoT networks have been instrumental in advancing the city’s industrial automation initiatives, allowing for improved decision-making and operational efficiency.

Additionally, engaging with technology partners and industry experts is crucial for the successful implementation of IoT-enabled automation solutions. By collaborating with IoT solution providers and leveraging their expertise, firms can customize their automation systems to suit their specific operational needs. In Dubai, partnerships with leading IoT companies have enabled industrial firms to deploy state-of-the-art automation solutions that address the unique challenges of their industry, enhancing both productivity and competitiveness.

The Role of Executive Coaching in Advancing IoT Automation Initiatives

Executive coaching can play a pivotal role in helping business leaders and operations managers navigate the complexities of implementing IoT-enabled automation solutions. As digital transformation accelerates across Saudi Arabia and the UAE, executives must stay informed about the latest advancements in IoT technology and their potential impact on industrial operations. Coaching services tailored to the specific needs of regional leaders can provide valuable insights and strategies for driving successful IoT automation initiatives.

Through executive coaching, leaders can develop a deeper understanding of how IoT-enabled automation solutions can be leveraged to achieve the firm’s strategic objectives. This knowledge allows them to make more informed decisions about technology investments, resource allocation, and organizational change, ensuring that their initiatives are aligned with the broader goals of operational excellence. By fostering a culture of innovation and continuous improvement, executive coaching can empower leaders to lead their organizations through the transformative journey of adopting IoT automation solutions.

Moreover, executive coaching can support leaders in building the necessary skills to manage cross-functional teams responsible for automation projects. Effective leadership is essential for navigating the challenges of integrating new technologies into existing systems while maintaining a strong focus on performance and efficiency. With the right coaching and support, executives in Dubai, Riyadh, and other key industrial hubs can confidently lead their organizations through the complexities of IoT-enabled automation management and digital transformation.

Conclusion: The Future of IoT-Enabled Automation in Industrial Firms

In conclusion, IoT-enabled automation solutions for higher productivity in industrial firms offer a powerful tool for enhancing operational efficiency, reducing costs, and improving competitiveness in Saudi Arabia, the UAE, and beyond. By leveraging the power of IoT technology, industrial firms can automate complex processes, reduce manual interventions, and achieve unprecedented levels of efficiency. As digital transformation continues to unfold, the adoption of IoT-enabled automation solutions will play a crucial role in shaping the future of industrial operations.

For business executives, mid-level managers, and operations leaders, understanding the potential of IoT-enabled automation solutions is essential for driving innovation and achieving long-term success. By investing in comprehensive automation strategies, fostering a culture of collaboration and data-driven decision-making, and leveraging executive coaching services, industrial firms can navigate the complexities of this emerging field and build a future-ready operation that leads in the era of smart manufacturing.

—

#IndustrialAutomation, #IoTSolutions, #ProductivityBoost, #DigitalTransformation, #SaudiArabiaIndustry, #UAEInnovation, #SmartManufacturing, #LeadershipDevelopment, #TechIntegration, #OperationalExcellence