Continuous Improvement Through IoT-Enabled Safety Practices

The Role of IoT in Enhancing Industrial Safety Standards

IoT technology for safety practices in industry is revolutionizing the way safety standards are maintained and continuously improved. By integrating IoT devices into industrial operations, companies can monitor equipment, environments, and even personnel in real-time, ensuring that potential hazards are identified and addressed before they lead to incidents. This proactive approach not only enhances safety but also supports compliance with stringent regulatory requirements in regions like Saudi Arabia, the UAE, Riyadh, and Dubai, where industrial innovation is a priority. The data collected through IoT sensors provides invaluable insights that can be analyzed to optimize safety protocols, reducing the likelihood of accidents and improving overall operational efficiency.

Real-Time Monitoring and Predictive Maintenance

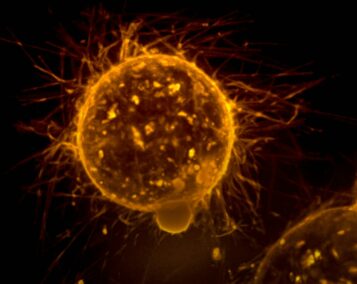

The implementation of IoT technology in industrial settings allows for real-time monitoring of equipment and infrastructure, which is crucial for maintaining high safety standards. Sensors can detect anomalies, such as temperature fluctuations, pressure changes, or unusual vibrations, that might indicate potential failures or hazards. By using predictive analytics, these IoT systems can forecast when maintenance is required, preventing unexpected breakdowns that could lead to dangerous situations. In bustling industrial hubs like Dubai and Riyadh, where uninterrupted operations are critical, this capability not only ensures safety but also minimizes downtime, thereby enhancing productivity and profitability.

Data-Driven Decision-Making for Safety Improvements

One of the most significant advantages of using IoT technology for safety practices in industry is the ability to make data-driven decisions. The continuous stream of data from IoT devices provides a comprehensive view of safety performance across all levels of operation. This data can be analyzed to identify trends, pinpoint areas of concern, and implement targeted improvements. For example, in industries where hazardous materials are handled, IoT technology can monitor environmental conditions and trigger alarms if thresholds are exceeded, allowing for immediate action. The ability to leverage real-time data empowers business executives and safety managers in places like Saudi Arabia and the UAE to enhance their safety protocols, ensuring a safer working environment for all employees.

Innovation in Safety Practices through IoT Integration

Automation and Control Systems for Enhanced Safety

The integration of IoT technology into industrial automation and control systems is a game-changer for safety practices. Automated systems powered by IoT can take over tasks that are hazardous for humans, such as handling dangerous chemicals or operating heavy machinery. In advanced industrial sectors across the Middle East, particularly in Saudi Arabia and Dubai, where the push for modernization and technological adoption is strong, IoT-enabled automation ensures that safety is not compromised as industries evolve. These systems can be programmed to respond to emergencies by shutting down operations, activating safety protocols, or alerting emergency services, all without human intervention, thereby significantly reducing the risk of accidents.

Training and Simulation Using IoT Data

IoT technology also plays a crucial role in the training and development of safety practices within the industry. By analyzing data collected from IoT devices, companies can create realistic simulations that replicate potential hazards in a controlled environment. This allows employees to practice their responses to various emergency scenarios, enhancing their preparedness for real-world situations. In regions like Riyadh and Dubai, where industrial growth is rapid, ensuring that the workforce is well-trained and capable of handling emergencies is essential. IoT-driven simulations provide a practical, data-informed approach to training, ensuring that safety protocols are not just theoretical but grounded in actual operational data.

Collaborative Innovation for Future Safety Standards

The adoption of IoT technology for safety practices is not just about improving current standards but also about fostering innovation for future safety protocols. As industries in the UAE and Saudi Arabia continue to expand and evolve, collaboration between IoT developers, industry experts, and regulatory bodies will be essential in setting new benchmarks for safety. The data generated by IoT devices offers a wealth of information that can be used to develop more sophisticated safety systems, tailored to the specific needs of different industries. This collaborative approach will ensure that as new technologies emerge, they are integrated into safety practices in a way that enhances protection for all stakeholders, from workers on the ground to executives in the boardroom.

In conclusion, IoT technology for safety practices in industry offers significant advantages, from real-time monitoring and predictive maintenance to automation and data-driven decision-making. As industries in Saudi Arabia, the UAE, Riyadh, and Dubai continue to embrace technological innovation, the integration of IoT into safety protocols will play a crucial role in ensuring that these advancements are accompanied by enhanced safety measures. The continuous improvement and innovation driven by IoT will not only protect workers and assets but also contribute to the overall success and sustainability of industrial operations.

—

#IoT #IndustrialSafety #Innovation #SafetyTech #IoTInIndustry #SmartIndustry #Automation #DataDrivenSafety #MiddleEastTech #IndustrialInnovation