The Integration of IoT in Industrial Robotics

IoT-enhanced industrial robots for precision and efficiency are revolutionizing the manufacturing sector, particularly in forward-looking regions like Saudi Arabia and the UAE. By integrating IoT technology into robotic systems, companies are achieving unprecedented levels of accuracy and operational effectiveness. This evolution is crucial for businesses aiming to stay competitive in an increasingly automated global market, where precision and efficiency are key drivers of success.

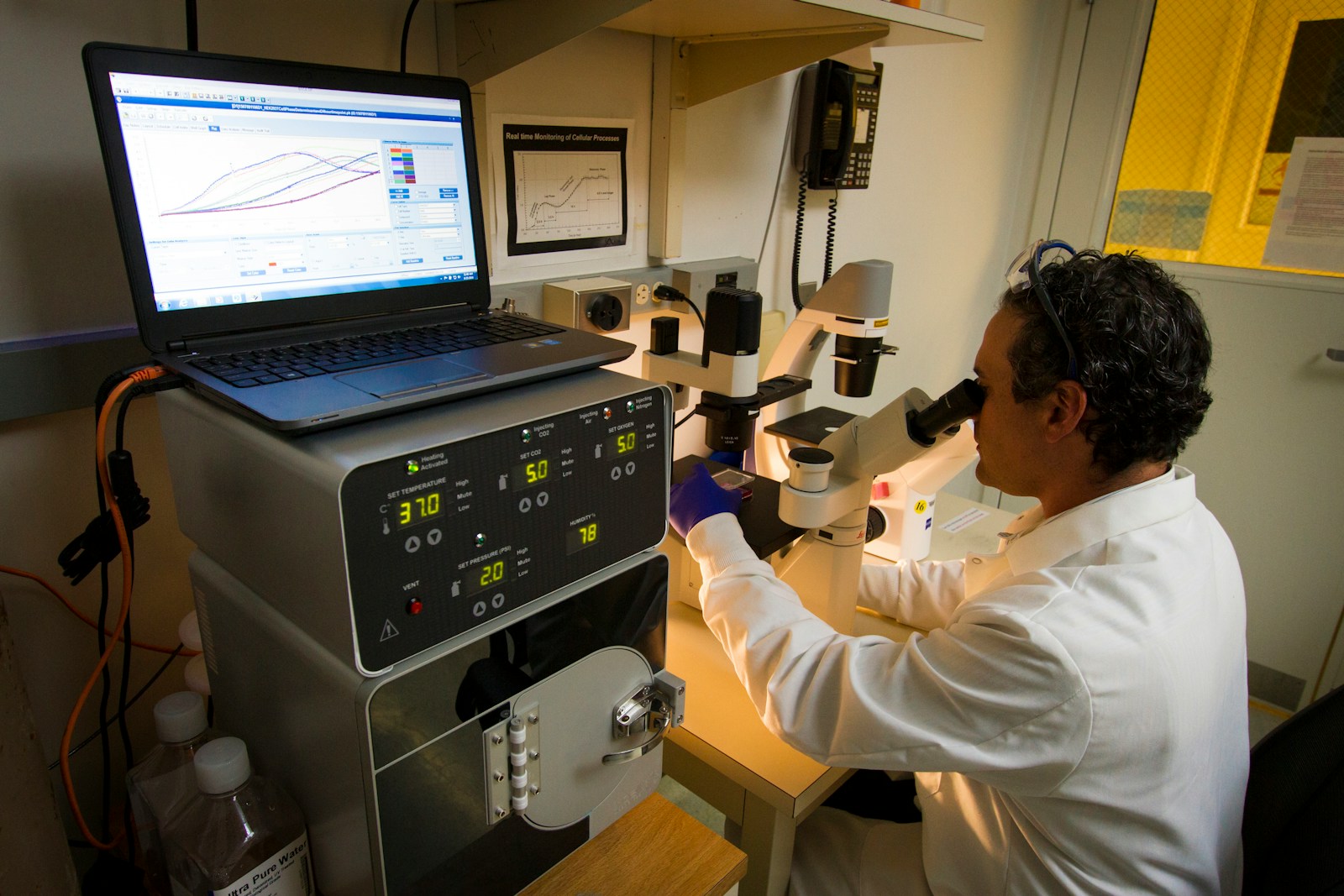

Industrial robots have long been a cornerstone of modern manufacturing, performing tasks with a level of speed and consistency that far surpasses human capabilities. However, the advent of IoT technology is taking these capabilities to new heights. Through IoT, robots can now connect to a vast network of sensors, devices, and systems, allowing for real-time data exchange and collaboration. This connectivity enables robots to make informed decisions based on real-time data, thereby enhancing their precision and efficiency. For instance, in a Riyadh-based automotive manufacturing plant, IoT-enabled robots can adjust their operations dynamically, responding instantly to changes in the production line, such as variations in material quality or unexpected equipment malfunctions.

Furthermore, IoT technology allows for the continuous monitoring and optimization of robotic systems. By collecting and analyzing data from various sensors, IoT platforms can provide insights into robot performance, identifying areas where improvements can be made. This capability is particularly valuable in the UAE’s rapidly growing manufacturing sector, where maintaining high standards of precision and efficiency is essential for meeting global quality benchmarks. With IoT-enhanced industrial robots, manufacturers can ensure that their operations run smoothly and efficiently, minimizing downtime and reducing waste.

Precision and Efficiency: The Twin Pillars of IoT-Enhanced Robotics

The integration of IoT technology into industrial robotics is significantly boosting both precision and efficiency, two critical factors in modern manufacturing. Precision is achieved through the robot’s ability to access real-time data from IoT-connected devices and sensors, allowing it to adjust its movements and operations with exacting accuracy. For example, in electronics manufacturing, where components are often minuscule and require precise placement, IoT-enabled robots can achieve tolerances that were previously unattainable.

In addition to enhancing precision, IoT technology greatly improves the efficiency of industrial robots. By enabling robots to communicate with other machines and systems within a smart factory, IoT facilitates seamless coordination across the production line. This interconnectedness reduces the likelihood of bottlenecks and ensures that every stage of the manufacturing process operates at peak efficiency. For instance, in a Dubai-based textile factory, IoT-enabled robots can synchronize with other machinery to optimize fabric cutting and sewing processes, thereby maximizing output while minimizing material waste.

Moreover, the real-time data provided by IoT allows manufacturers to implement predictive maintenance strategies, further enhancing efficiency. By monitoring the condition of robotic components, IoT systems can predict when maintenance is needed, preventing unexpected breakdowns and costly downtime. This proactive approach to maintenance is particularly important in high-volume production environments, where even a brief interruption can lead to significant financial losses. In Saudi Arabia’s burgeoning industrial sector, the adoption of IoT-enhanced robotics is proving to be a game-changer, enabling companies to achieve higher levels of productivity and profitability.

The Future of Manufacturing with IoT-Enabled Robotics

Scalability and Customization: The Next Frontier

As the integration of IoT technology in industrial robotics continues to evolve, the future of manufacturing is poised to be more scalable and customizable than ever before. IoT-enhanced robots offer the flexibility to adapt to a wide range of manufacturing environments, from small-scale production facilities to large, complex factories. This scalability is particularly important for companies in Saudi Arabia and the UAE, where rapid industrial growth demands adaptable solutions that can scale in response to increasing production demands.

Customization is another key advantage of IoT-enhanced robotics. By leveraging IoT data, manufacturers can tailor robotic operations to meet specific production requirements, whether it’s adjusting the speed and precision of a robotic arm or modifying its programming to accommodate new product lines. This level of customization is invaluable in industries where product variation is high, such as consumer electronics or automotive manufacturing. In Dubai, where the market demands a high degree of product differentiation, IoT-enabled robots are enabling manufacturers to meet customer expectations with greater speed and flexibility.

Moreover, the ability to remotely monitor and control IoT-enabled robots through cloud-based platforms is opening new possibilities for global manufacturing operations. Companies can now manage and optimize their robotic systems from anywhere in the world, ensuring consistent performance across multiple facilities. This capability is particularly beneficial for multinational corporations with operations in both Saudi Arabia and the UAE, as it allows for centralized management of production processes, reducing operational costs and enhancing overall efficiency.

Conclusion: Embracing IoT for a Competitive Edge in Manufacturing

In conclusion, the integration of IoT technology into industrial robotics is a transformative development that is enhancing precision and efficiency in manufacturing. For businesses in Saudi Arabia, the UAE, and beyond, adopting IoT-enhanced industrial robots is not just a trend but a strategic necessity. By leveraging the power of IoT, manufacturers can optimize their operations, reduce costs, and maintain a competitive edge in the global market. As the technology continues to advance, the potential for IoT-enabled robotics to revolutionize the manufacturing sector will only grow, offering new opportunities for innovation and growth.

—

#IoTRobotics #PrecisionManufacturing #SmartFactories #IndustrialEfficiency #AdvancedRobotics #SaudiArabia #UAE #IoTIntegration #ManufacturingTechnology #GlobalIndustry