The Role of Predictive Maintenance in Enhancing Equipment Longevity

Understanding Predictive Maintenance in Factory Settings

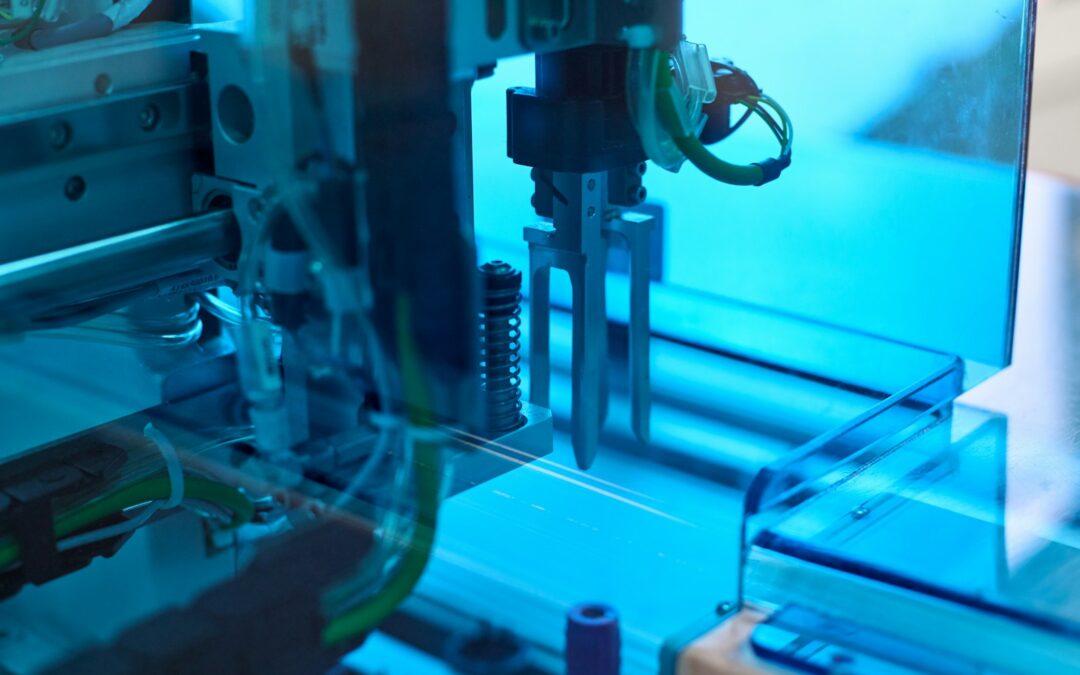

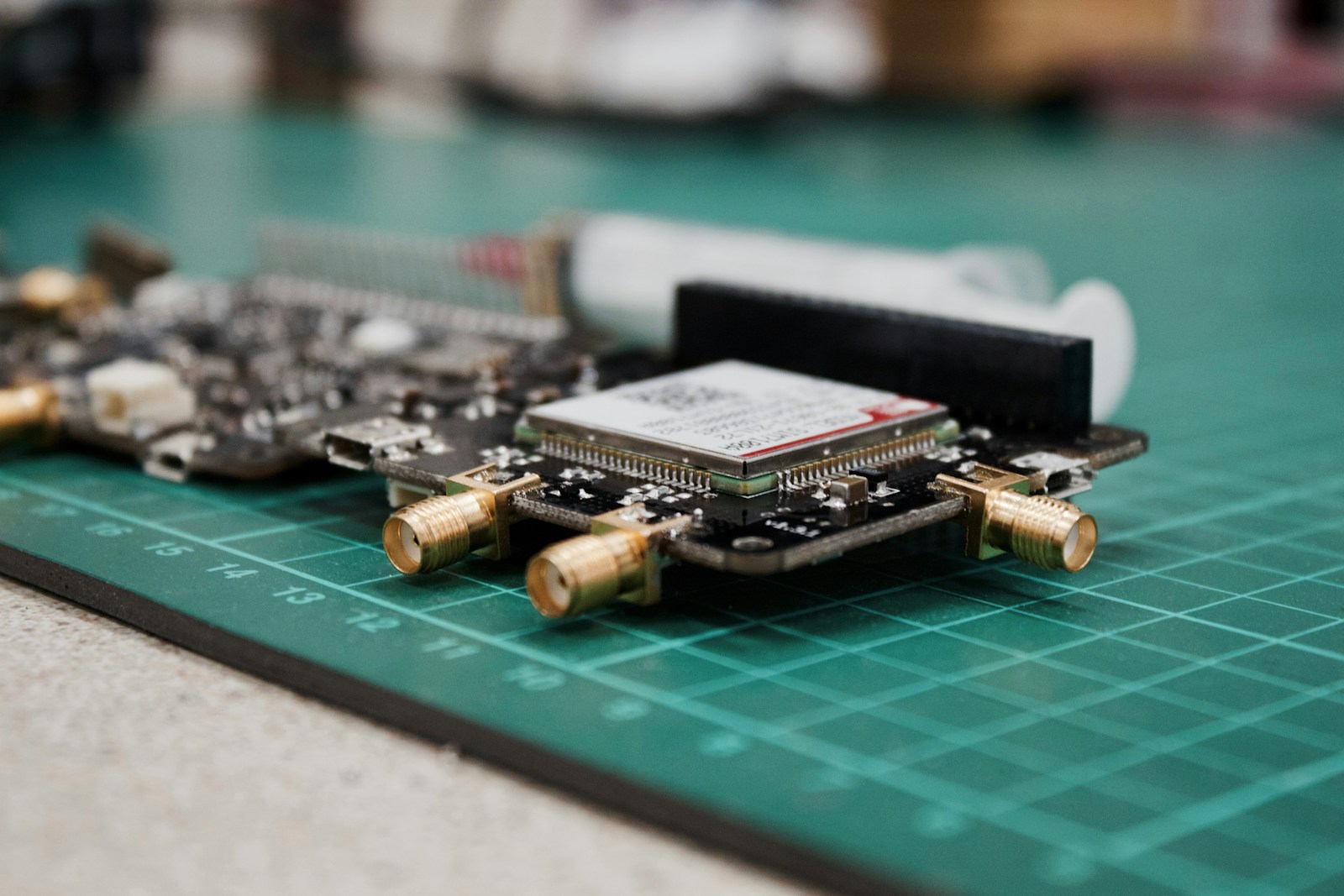

Predictive maintenance in extending machinery lifespan is a transformative approach that leverages data analytics and IoT technologies to monitor the health of equipment and predict potential failures before they occur. By implementing predictive maintenance strategies, factories can identify wear and tear, unusual vibrations, and other indicators of equipment degradation early, allowing for timely interventions that prevent costly breakdowns. This proactive maintenance model is especially relevant in high-demand industrial settings such as those in Riyadh and Dubai, where uninterrupted production is crucial for business success. By extending the lifespan of machinery, predictive maintenance not only reduces operational costs but also enhances the overall efficiency of manufacturing processes.

How Predictive Analytics Drives Maintenance Decisions

Predictive maintenance relies heavily on predictive analytics, utilizing data from sensors and IoT devices to forecast when maintenance should be performed. In factories across Saudi Arabia, this approach allows maintenance teams to move away from traditional reactive maintenance, which often results in unexpected downtime and increased costs. Instead, predictive maintenance provides a data-driven roadmap for servicing equipment only when needed, based on real-time insights into the machine’s condition. For instance, in Dubai’s manufacturing sector, predictive maintenance has been instrumental in optimizing maintenance schedules, reducing unnecessary inspections, and ensuring that machinery operates at peak efficiency. This not only extends the lifespan of the equipment but also boosts the factory’s productivity by minimizing unplanned interruptions.

Cost Savings Through Efficient Resource Utilization

One of the significant benefits of predictive maintenance is the cost savings achieved through efficient resource utilization. By accurately predicting when machinery components are likely to fail, factories can order replacement parts just in time, reducing inventory costs and storage requirements. In Riyadh, for example, manufacturers using predictive maintenance have reported a reduction in maintenance-related expenditures by up to 30%. This approach not only saves money but also optimizes labor by preventing the need for emergency repairs that can disrupt production schedules. As factories continue to seek ways to remain competitive in a global market, predictive maintenance offers a strategic advantage by ensuring that equipment is reliable, efficient, and long-lasting.

Enhancing Factory Operations with Predictive Maintenance

Reducing Downtime with Proactive Maintenance Strategies

Predictive maintenance plays a pivotal role in reducing downtime, a critical factor in maintaining productivity and profitability in factory operations. By continuously monitoring machinery conditions, predictive maintenance systems can alert operators to potential issues before they lead to a breakdown. This proactive approach allows for maintenance to be scheduled during non-peak hours or planned shutdowns, minimizing the impact on production. In Dubai, where factories operate on tight schedules to meet international demands, predictive maintenance ensures that operations run smoothly without the disruptions caused by unexpected machinery failures. This capability not only extends the lifespan of the machinery but also contributes to a more predictable and manageable production environment.

Improving Safety and Compliance in Manufacturing

Beyond extending machinery lifespan and reducing costs, predictive maintenance also enhances safety and compliance within factories. Faulty machinery can pose significant safety risks to workers, leading to accidents and injuries. By identifying potential equipment failures early, predictive maintenance helps factories maintain safe working conditions, protecting employees and reducing the likelihood of costly regulatory fines. In Saudi Arabia, where industrial safety standards are stringent, adopting predictive maintenance aligns with the country’s broader goals of improving workplace safety and operational excellence. Furthermore, by ensuring that machinery is always in optimal condition, factories can meet compliance requirements more easily, avoiding the penalties associated with equipment-related non-compliance.

The Future of Predictive Maintenance in Smart Manufacturing

As factories continue to adopt digital transformation strategies, the role of predictive maintenance in extending machinery lifespan is set to grow even more critical. The integration of advanced technologies such as AI and machine learning with predictive maintenance systems will enhance the accuracy of failure predictions and enable more sophisticated maintenance planning. In Riyadh and Dubai, where smart manufacturing is on the rise, predictive maintenance will be a cornerstone of the modern factory, supporting continuous improvement and operational efficiency. Additionally, as IoT devices become more advanced, the granularity and reliability of data collected will further refine predictive maintenance models, making them indispensable tools for maintaining the health and longevity of factory equipment.

Conclusion

In conclusion, predictive maintenance is a powerful tool for extending the lifespan of machinery in factories, offering numerous benefits, including cost savings, reduced downtime, enhanced safety, and improved operational efficiency. By leveraging predictive analytics and IoT technologies, factories in Riyadh, Dubai, and beyond can move from reactive to proactive maintenance strategies, ensuring that their equipment remains in optimal condition for longer periods. As the manufacturing industry continues to evolve, the adoption of predictive maintenance will be essential for factories aiming to maintain a competitive edge, enhance their production capabilities, and contribute to a safer and more efficient industrial environment.

—

#PredictiveMaintenance #MachineryLifespan #SmartManufacturing #FactoryEfficiency #IoT #DigitalTransformation #Riyadh #Dubai