Implementing Predictive Maintenance with IoT in Saudi Arabia and UAE Factories

Enhancing Factory Operations with Predictive Maintenance Using IoT

Predictive maintenance with IoT in factories is revolutionizing industrial operations, offering significant cost savings and efficiency improvements in regions like Saudi Arabia and the UAE. By leveraging IoT sensors and advanced analytics, factories can anticipate equipment failures before they occur, reducing downtime and maintenance costs. This proactive approach to maintenance ensures that machinery operates at optimal efficiency, minimizing disruptions and extending the lifespan of assets. In Riyadh and Dubai, where manufacturing and industrial sectors are key contributors to economic growth, implementing predictive maintenance with IoT has become a strategic priority for enhancing competitiveness and operational excellence.

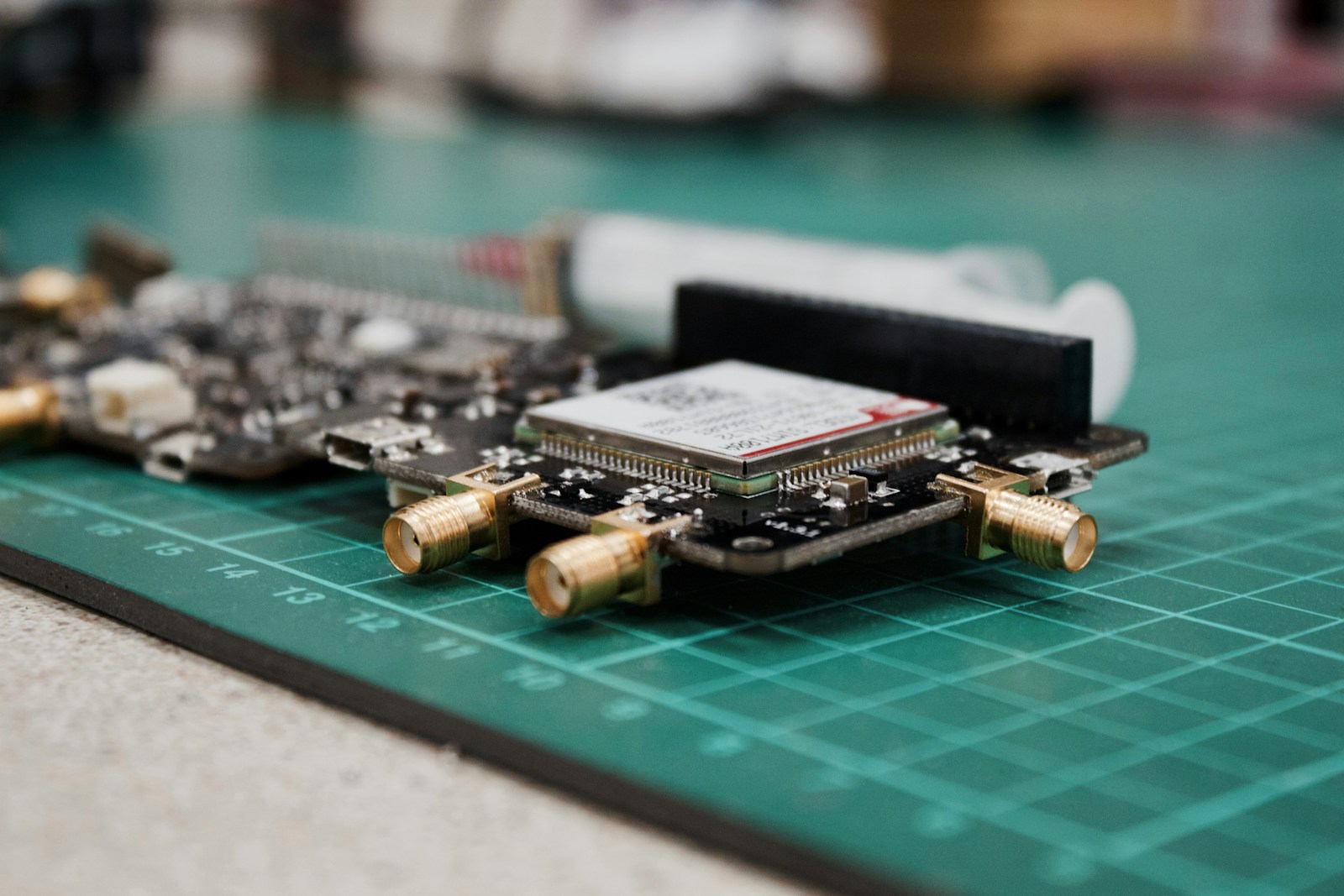

One of the primary benefits of predictive maintenance using IoT solutions is the ability to monitor equipment health in real time. IoT sensors installed on critical machinery collect data on various parameters such as vibration, temperature, and pressure, which are then analyzed to identify potential issues. For instance, in a manufacturing plant in Riyadh, IoT-enabled predictive maintenance allowed the factory to detect early signs of motor wear in its production line. By addressing the issue before it led to a complete breakdown, the factory avoided costly repairs and production delays, resulting in substantial cost savings. This approach not only enhances operational reliability but also optimizes maintenance schedules, ensuring that resources are allocated efficiently.

In Dubai, predictive maintenance with IoT solutions has been instrumental in optimizing energy consumption in factories. IoT sensors monitor the energy usage of equipment, identifying patterns and anomalies that indicate inefficiencies. By analyzing this data, factories can implement energy-saving measures, such as adjusting machine settings or scheduling maintenance during off-peak hours. This not only reduces energy costs but also aligns with Dubai’s broader sustainability goals of reducing carbon emissions and promoting eco-friendly industrial practices. The integration of predictive maintenance with IoT into factory operations thus provides a dual benefit of cost reduction and environmental stewardship, making it a valuable strategy for businesses in the region.

Optimizing Factory Efficiency and Reducing Operational Costs with IoT

Predictive maintenance with IoT solutions also plays a critical role in optimizing overall factory efficiency by reducing unplanned downtime and improving asset utilization. In Saudi Arabia, where industrial sectors are rapidly modernizing under the Vision 2030 initiative, the adoption of IoT-enabled predictive maintenance is helping factories achieve higher levels of productivity and cost-effectiveness. For example, in a Riyadh-based factory specializing in automotive parts, predictive maintenance systems use IoT data to forecast when machinery is likely to fail based on historical performance and current operating conditions. This foresight allows maintenance teams to schedule repairs during planned downtime, minimizing the impact on production schedules and avoiding the high costs associated with emergency repairs.

Furthermore, predictive maintenance with IoT solutions facilitates better inventory management by ensuring that spare parts are only ordered when needed. In Dubai’s manufacturing sector, factories that employ IoT-enabled predictive maintenance can accurately predict which components are likely to wear out soon, allowing them to maintain lean inventories. This reduces the capital tied up in spare parts and lowers storage costs, contributing to overall cost savings. Additionally, by preventing unnecessary replacements, factories can reduce waste and support more sustainable manufacturing practices, aligning with Dubai’s vision of becoming a hub for green and innovative industries.

Another significant advantage of predictive maintenance with IoT in factories is the enhancement of worker safety. By predicting and preventing equipment failures, IoT solutions reduce the likelihood of accidents caused by malfunctioning machinery. In industrial environments, where safety is paramount, this proactive approach not only protects workers but also reduces the costs associated with workplace injuries, such as medical expenses, compensation claims, and lost productivity. In Riyadh, factories that have implemented IoT-enabled predictive maintenance report not only improved operational performance but also a safer working environment, which is crucial for maintaining employee morale and compliance with safety regulations.

Conclusion: The Impact of Predictive Maintenance with IoT on Factory Cost Savings

In conclusion, predictive maintenance with IoT in factories is a game-changer for industrial operations in Saudi Arabia and the UAE, offering a powerful tool for achieving cost savings and operational excellence. By leveraging real-time data and predictive analytics, factories can anticipate equipment failures, optimize maintenance schedules, and reduce unplanned downtime, all of which contribute to significant cost reductions. In cities like Riyadh and Dubai, where the drive towards digital transformation is reshaping industries, the implementation of predictive maintenance with IoT is not just a technological upgrade but a strategic imperative for staying competitive in the global market.

As more factories in Saudi Arabia and the UAE adopt IoT-enabled predictive maintenance, the benefits are expected to extend beyond cost savings to include enhanced efficiency, improved safety, and greater sustainability. By embracing this innovative approach, factories can not only meet the immediate challenges of maintenance and downtime but also position themselves for long-term success in an increasingly digital and connected industrial landscape. The future of manufacturing in Saudi Arabia and the UAE is bright, and with predictive maintenance powered by IoT, factories are well-equipped to navigate the path towards greater efficiency, resilience, and profitability.

—

#PredictiveMaintenance, #IoTSolutions, #FactoryEfficiency, #SaudiArabiaInnovation, #UAEManufacturing, #DigitalTransformation, #SmartManufacturing, #CostSavings, #ModernTechnology, #IndustrialAutomation