Understanding the Integration of Machine Learning in Predictive Maintenance

Strategic Planning for Machine Learning Integration

Implementing machine learning for predictive maintenance in manufacturing requires careful strategic planning to ensure successful integration and deployment. For businesses in Saudi Arabia and the UAE, embracing this technology involves assessing the current maintenance practices and identifying areas where machine learning can add significant value. The initial step is to conduct a thorough evaluation of existing maintenance data and systems. This includes reviewing historical maintenance records, equipment performance data, and operational workflows. By understanding these elements, organizations can determine the most relevant machine learning models and algorithms to apply, thus aligning their predictive maintenance strategies with their specific needs and objectives.

Additionally, it is crucial to establish clear goals and success metrics for the machine learning implementation. Defining these objectives will guide the selection of appropriate tools and technologies, as well as help in measuring the impact of the new system. For instance, businesses in Riyadh and Dubai should set targets related to reduced downtime, increased equipment lifespan, and improved operational efficiency. By setting precise, measurable goals, companies can track progress and make necessary adjustments to enhance the effectiveness of their predictive maintenance programs.

Data Quality and Management for Effective Predictive Maintenance

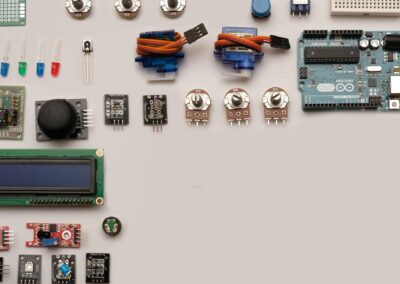

A key consideration for implementing machine learning for predictive maintenance is ensuring high-quality data management. Accurate and comprehensive data is the foundation of any successful machine learning model. In manufacturing settings, this involves collecting data from various sources, such as IoT sensors, machinery logs, and environmental conditions. Businesses in Saudi Arabia and the UAE must invest in robust data collection infrastructure to capture relevant information. This includes deploying advanced sensors and integrating data collection systems that provide real-time insights into equipment performance and condition.

Moreover, data quality must be maintained through regular validation and cleaning processes. This ensures that the information fed into machine learning algorithms is accurate and free from anomalies that could skew results. Effective data management practices are essential for building reliable predictive models that can accurately forecast equipment failures and maintenance needs. By focusing on data quality and management, companies can enhance the precision of their predictive maintenance efforts and achieve more reliable outcomes.

Choosing the Right Machine Learning Models and Tools

Selecting the appropriate machine learning models and tools is another critical aspect of implementing predictive maintenance solutions. Different models may be suited to various types of equipment and maintenance scenarios. For businesses in Dubai and Riyadh, it is important to collaborate with experts who can recommend and tailor machine learning models to their specific operational requirements. This might involve choosing between supervised learning models, which require labeled data, or unsupervised learning models, which can identify patterns in unlabeled data.

In addition to selecting the right models, businesses must also consider the integration of machine learning tools with existing maintenance management systems. This ensures that predictive maintenance insights can be seamlessly incorporated into daily operations. Companies should prioritize tools that offer user-friendly interfaces and robust support for data integration. By choosing the right models and tools, businesses can optimize their predictive maintenance strategies and enhance their overall operational efficiency.

Addressing Integration Challenges and Change Management

Implementing machine learning for predictive maintenance involves navigating various integration challenges and managing organizational change. Integrating advanced technologies into existing systems can be complex, requiring careful coordination and planning. Businesses in Saudi Arabia and the UAE should develop a detailed implementation plan that includes technical considerations, resource allocation, and timeline management. Effective change management practices are essential to ensure a smooth transition and to address any resistance from staff. Training programs and clear communication about the benefits of machine learning can help in gaining buy-in from employees and fostering a culture of innovation.

Furthermore, it is important to establish a dedicated team to oversee the implementation process. This team should include experts in machine learning, data analysis, and maintenance management. By assembling a knowledgeable team and providing them with the necessary resources and support, businesses can effectively manage the integration of machine learning solutions and ensure their successful deployment.

#MachineLearningForPredictiveMaintenance #PredictiveMaintenanceInManufacturing #AIInMaintenance #SaudiArabiaTechnology #UAEInnovations #RiyadhManufacturing #DubaiBusinessSolutions #ManagementConsulting #ExecutiveCoaching #EffectiveCommunication #BusinessSuccess