Transforming Manufacturing with IoT Device Integration on the Shop Floor: How to Integrate Shop Floor Devices Using IoT Connectors

In the realm of modern manufacturing, the focus on integrating shop floor devices using it connectors is pivotal for businesses looking to enhance operational efficiency and embrace the digital transformation. This article aims to provide an in-depth understanding for business executives, mid-level managers, and entrepreneurs about the significance and benefits of leveraging the Internet of Things (IoT) connectors in manufacturing processes.

The Growing Importance of IoT in Manufacturing

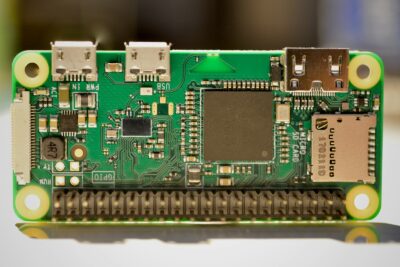

In the transformative era of Industry 4.0, the Internet of Things (IoT) has emerged as a revolutionary force, revolutionizing the manufacturing landscape by seamlessly integrating physical devices embedded with sensors, software, and other technologies into a vast interconnected network. This network of intelligent devices, capable of collecting, analyzing, and exchanging data over the Internet, has unlocked a plethora of transformative benefits for the manufacturing industry, paving the way for real-time monitoring, enhanced data accuracy, and unprecedented levels of production efficiency.

The seamless integration of IoT devices into the manufacturing shop floor has transformed the way manufacturers monitor and control their operations. By embedding sensors and other data-gathering devices into machinery, equipment, and even raw materials, manufacturers can continuously gather real-time insights into the status of their production processes. This real-time data stream provides a comprehensive view of the entire manufacturing process, enabling proactive identification and resolution of potential issues before they escalate into major disruptions.

The ability to collect and analyze real-time data from IoT devices has also led to significant improvements in data accuracy. Traditional data collection methods, often relying on manual data entry and periodic measurements, were prone to human error and inconsistencies. IoT devices, with their continuous data streams and automated data collection capabilities, eliminate the risk of human error and provide a consistent, high-quality data source. This enhanced data accuracy empowers manufacturers to make data-driven decisions with greater confidence, optimizing processes, improving product quality, and reducing costs.

Furthermore, the integration of IoT devices has revolutionized production efficiency by enabling the automation of tasks, optimization of resource utilization, and predictive maintenance. By connecting machines and devices to a central network, manufacturers can automate repetitive tasks, such as machine monitoring and data collection, freeing up human workers to focus on higher-value activities. Additionally, IoT-powered analytics can optimize resource utilization by identifying and eliminating inefficiencies in production processes, such as energy consumption or material waste.

Moreover, IoT devices play a pivotal role in predictive maintenance, enabling manufacturers to anticipate equipment failures and proactively address potential issues before they cause costly downtime. By analyzing data from sensors and monitoring equipment performance, manufacturers can identify early signs of wear and tear, scheduling maintenance activities before equipment breakdowns occur. This proactive approach to maintenance minimizes unplanned downtime, enhances operational efficiency, and extends the lifespan of critical equipment.

In essence, the integration of IoT devices into the manufacturing landscape has ushered in an era of unprecedented connectivity, data-driven decision-making, and enhanced production efficiency. By harnessing the power of IoT, manufacturers can gain real-time insights into their operations, improve data accuracy, optimize resource utilization, and implement predictive maintenance strategies, ultimately propelling their businesses towards sustainable growth and success in the transformative era of Industry 4.0.

Advantages of IoT Device Integration in Manufacturing

IoT device integration facilitates more efficient and error-free manufacturing processes. It enables real-time data collection and analysis, leading to better decision-making, predictive maintenance, and ultimately, increased productivity. Moreover, it enhances quality control and streamlines inventory management.

Change Management for IoT Integration

Adopting IoT technology on the shop floor requires a robust change management approach. This transition involves not only technological upgrades but also a shift in the organizational culture and processes. Effective change management ensures smooth integration of IoT connectors and aligns the workforce with new digital practices.

Executive Coaching for IoT Implementation Leadership

Executive coaching is crucial in preparing leaders for the challenges of IoT integration. It equips them with the necessary skills and knowledge to manage the technological and human aspects of this transition effectively, fostering a culture of innovation and continuous improvement.

Leveraging Generative AI in IoT-Driven Manufacturing

Generative Artificial Intelligence (AI) can play a significant role in enhancing IoT-based manufacturing systems. AI algorithms can analyze the vast amount of data generated by IoT devices to optimize production processes, predict equipment failures, and improve product design and quality.

Effective Communication in IoT Implementation

Effective communication is vital for successful IoT integration on the shop floor. It involves educating the workforce about the benefits and workings of IoT technology, addressing concerns, and fostering an environment of collaboration and openness to change.

Project Management in IoT Initiatives

Effective project management is critical for the successful implementation of IoT connectors in manufacturing. It requires strategic planning, resource allocation, and continuous monitoring to ensure that IoT integration aligns with business objectives and delivers the desired outcomes.

Conclusion: Embracing IoT for Future-Ready Manufacturing

In conclusion, integrating shop floor devices using IoT connectors is a strategic move for manufacturers aiming to optimize their operations and stay competitive in the digital age. By embracing effective change management, executive coaching, generative AI, and robust project management, businesses can successfully navigate the complexities of IoT integration and harness its full potential for operational excellence.

#IoTManufacturing #DigitalTransformation #SmartFactory #ExecutiveCoaching #GenerativeAI #ProjectManagement