Optimizing Workflow Efficiency through Object Detection Integration

Understanding the Impact of Object Detection on Workflow Optimization

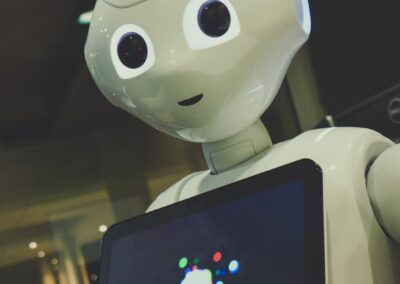

Integrating object detection systems into existing workflows is a strategic move that can significantly enhance operational efficiency and accuracy. In rapidly developing regions like Saudi Arabia and the UAE, where technological innovation is driving business success, the adoption of AI-driven solutions such as object detection is becoming increasingly critical. Object detection technology, powered by artificial intelligence, enables businesses to automate the identification and analysis of visual data, leading to faster decision-making and reduced manual intervention. However, to fully realize the benefits of this technology, it is essential to carefully consider how it will impact existing workflows and processes.

One of the primary considerations when integrating object detection systems into workflows is understanding the specific needs and objectives of the business. For instance, in sectors like retail, manufacturing, or logistics, the implementation of object detection can streamline inventory management, quality control, and security operations. However, to achieve these outcomes, businesses must ensure that the technology is tailored to their unique requirements. This involves selecting the right tools and algorithms that can accurately detect and classify objects relevant to their operations, whether it’s identifying products on shelves, monitoring assembly lines, or tracking shipments.

Ensuring Seamless Integration and Long-Term Success

While the benefits of integrating object detection systems into existing workflows are clear, achieving seamless integration requires careful planning and execution. One of the key challenges is ensuring that the new technology is compatible with existing systems and applications. This is particularly important in industries where legacy systems are prevalent, and where disruptions to workflows can have significant operational and financial implications. To address this, businesses must invest in robust integration solutions that allow object detection systems to interface seamlessly with their current infrastructure. This may involve updating software, reconfiguring hardware, or even redesigning workflows to accommodate the new technology.

Another critical consideration is the training and support required to ensure that employees can effectively use and manage object detection systems. In regions like Saudi Arabia and the UAE, where there is a strong emphasis on workforce development and leadership skills, providing comprehensive training programs is essential. These programs should not only cover the technical aspects of operating object detection systems but also focus on change management and effective communication strategies. By equipping employees with the knowledge and skills they need to leverage this technology, businesses can ensure a smooth transition and minimize resistance to change.

Maximizing ROI through Strategic Object Detection Integration

Integrating object detection systems into existing workflows is not just about enhancing operational efficiency; it is also about driving business success through strategic innovation. In competitive markets like those in Saudi Arabia and the UAE, businesses that can effectively leverage AI-driven technologies like object detection are better positioned to achieve their strategic goals and maintain a competitive edge. By optimizing workflows, improving accuracy, and reducing costs, object detection systems can significantly contribute to business success.

To maximize the return on investment (ROI) from object detection integration, businesses must take a strategic approach that aligns technology with their broader business objectives. This involves not only selecting the right tools and solutions but also ensuring that they are implemented in a way that delivers measurable results. For example, in retail, object detection can enhance customer experiences by providing personalized recommendations and streamlining checkout processes. In manufacturing, it can improve product quality by automating defect detection and reducing waste. By focusing on outcomes that directly impact the bottom line, businesses can ensure that their investment in object detection delivers tangible benefits.

#ObjectDetectionIntegration #AIinSaudiArabia #AIinUAE #WorkflowOptimization #BusinessSuccess #ManagementConsulting #AIinRiyadh #AIinDubai #ChangeManagement #DigitalTransformation #ArtificialIntelligence #LeadershipSkills