Real-Time Data and Enhanced Visibility

One of the most significant advantages of utilizing IoT in supply chain management is the ability to obtain real-time data. Traditional supply chain systems often rely on periodic updates and manual reporting, which can result in outdated or inaccurate information. IoT sensors, however, continuously gather data on various parameters, such as temperature, location, and inventory levels, and transmit this information instantly. This real-time data stream provides supply chain managers with a comprehensive view of their operations, enabling them to track shipments, monitor the status of goods, and respond promptly to any issues. For example, in the context of logistics, IoT-enabled tracking systems can provide precise locations of shipments, reducing the uncertainty and improving delivery accuracy.

Improved Coordination and Efficiency

With the implementation of IoT, coordination across the supply chain becomes significantly more streamlined. Traditional systems may have gaps in communication between different stakeholders, such as suppliers, manufacturers, and distributors, leading to delays and inefficiencies. IoT technology bridges these gaps by facilitating seamless data sharing and communication. For instance, automated alerts can be sent to relevant parties when inventory levels fall below a certain threshold, or when a shipment deviates from its planned route. This proactive approach not only reduces the risk of stockouts and delays but also enhances overall efficiency by optimizing inventory management and logistics operations.

Predictive Analytics and Risk Management

Another key benefit of IoT in supply chain management is its ability to support predictive analytics. By analyzing the vast amounts of data collected from IoT devices, businesses can identify patterns and trends that may indicate potential issues or opportunities. Predictive analytics allows companies to anticipate disruptions, such as supply chain bottlenecks or equipment failures, and take preemptive measures to mitigate risks. For example, if data from IoT sensors indicates that a piece of machinery is showing signs of wear, maintenance can be scheduled proactively, reducing the likelihood of unexpected breakdowns. This forward-looking approach enhances risk management and contributes to a more resilient and adaptable supply chain.

Transforming Supply Chain Operations with IoT Technology

Enhanced Inventory Management

The role of IoT in supply chain management extends significantly to inventory management. Traditional methods of tracking inventory can be labor-intensive and prone to errors, often relying on manual counts and periodic audits. IoT technology automates this process through smart shelves and RFID tags, providing real-time visibility into inventory levels and locations. This automation not only reduces the likelihood of stock discrepancies but also enables more accurate demand forecasting. With IoT, businesses can monitor inventory in real time, ensuring that stock levels are optimized and reducing the risk of overstocking or stockouts. This dynamic approach to inventory management enhances overall operational efficiency and supports better financial performance.

Streamlined Transportation and Logistics

Transportation and logistics are critical components of supply chain management that benefit greatly from IoT integration. Traditional logistics systems may struggle with route optimization and real-time tracking, leading to inefficiencies and increased costs. IoT-enabled solutions, such as GPS tracking and telematics, offer precise control over transportation operations. By analyzing data from IoT devices, companies can optimize delivery routes, monitor vehicle performance, and reduce fuel consumption. This real-time visibility allows for dynamic route adjustments based on traffic conditions or unforeseen delays, enhancing the efficiency of logistics operations and contributing to cost savings.

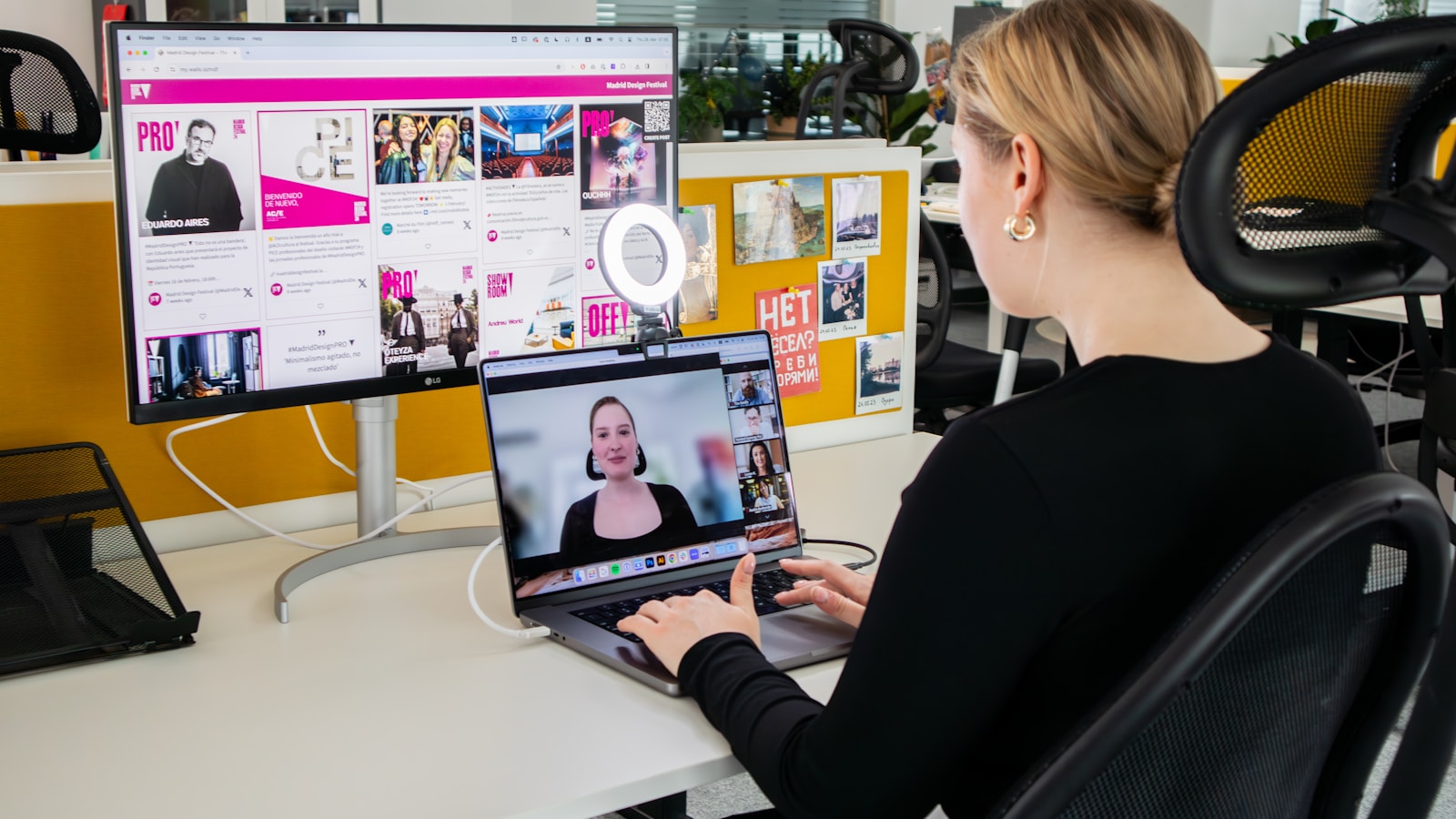

Enhanced Collaboration and Communication

Effective collaboration and communication among supply chain partners are crucial for operational success. IoT in supply chain management facilitates improved collaboration by providing a unified platform for data sharing and communication. Through IoT systems, all stakeholders can access the same real-time data, ensuring that everyone is aligned and informed. This shared visibility helps in coordinating activities, resolving issues more swiftly, and fostering a more collaborative environment. For instance, if a supplier encounters a delay, real-time data can immediately alert other partners, allowing them to adjust their plans and mitigate the impact on the overall supply chain.

Conclusion

The implementation of IoT in supply chain management marks a significant advancement from traditional systems, offering enhanced visibility, improved coordination, and greater efficiency. By leveraging real-time data, predictive analytics, and automated processes, businesses can transform their supply chain operations to be more agile, responsive, and cost-effective. As the global market continues to evolve, adopting IoT technology becomes increasingly essential for maintaining a competitive edge and achieving sustained business success. For organizations in Saudi Arabia, the UAE, Riyadh, and Dubai, embracing these modern technological solutions can drive significant improvements in supply chain performance and overall operational excellence.

#IoT #SupplyChainManagement #BusinessSuccess #TechnologyInBusiness #ModernSupplyChain #RealTimeData #LogisticsOptimization #InventoryManagement