The Critical Role of IoT in Proactive Maintenance

Understanding the Impact of IoT Proactive Maintenance Strategies

IoT proactive maintenance strategies are transforming the way businesses manage their assets, offering a significant shift from reactive to proactive maintenance approaches. In dynamic regions like Saudi Arabia and the UAE, where industries are rapidly evolving, the adoption of IoT technologies for proactive maintenance has become a cornerstone for minimizing unplanned downtime and reducing operational costs. By leveraging IoT sensors and analytics, companies can monitor the health of their equipment in real time, predict potential failures, and take corrective actions before issues escalate.

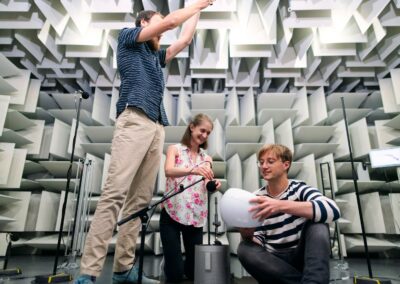

The implementation of IoT proactive maintenance strategies involves integrating smart sensors into machinery and equipment, which continuously collect data on various performance metrics such as temperature, vibration, and pressure. This data is then analyzed using advanced algorithms to detect patterns and anomalies that may indicate impending equipment failures. By identifying these issues early, maintenance teams can schedule repairs or replacements during planned downtime, thus avoiding unexpected breakdowns that could disrupt production and lead to costly delays.

Moreover, IoT-driven maintenance strategies enable businesses to optimize their maintenance schedules based on actual equipment conditions rather than relying on predetermined intervals. This approach not only extends the lifespan of assets but also ensures that maintenance resources are utilized efficiently, ultimately leading to significant cost savings. In regions like Riyadh and Dubai, where industries are looking to enhance their operational efficiency, IoT proactive maintenance is proving to be a game-changer.

Minimizing Unplanned Downtime with Predictive Maintenance

One of the most significant advantages of implementing is the ability to minimize unplanned downtime through predictive maintenance. Unplanned downtime can be incredibly costly, especially in industries such as manufacturing, oil and gas, and transportation, where even a few hours of inactivity can result in substantial financial losses. IoT-enabled predictive maintenance uses real-time data to forecast when equipment is likely to fail, allowing businesses to address potential issues before they cause disruptions.

In the context of large-scale industrial operations in the UAE and Saudi Arabia, predictive maintenance plays a vital role in ensuring continuous production and service delivery. By utilizing IoT sensors that monitor critical parameters, businesses can create a digital twin of their equipment—an exact virtual replica that mirrors the physical condition of the machinery. This digital twin provides valuable insights into the performance and wear of components, enabling maintenance teams to predict when failures might occur and plan maintenance activities accordingly.

For example, in the oil and gas sector, where equipment such as pumps and compressors operate under harsh conditions, IoT sensors can detect subtle changes in performance that might indicate wear and tear. By addressing these issues proactively, companies can prevent catastrophic failures that would otherwise result in prolonged downtime and costly repairs. Additionally, this approach allows for better inventory management, as maintenance teams can ensure that necessary spare parts are available when needed, reducing the time required for repairs.

Optimizing Costs and Resources through IoT-Driven Maintenance

Cost-Saving Benefits of IoT Proactive Maintenance

offer substantial cost-saving benefits by reducing the frequency and severity of equipment failures. Traditional maintenance approaches often involve either reactive maintenance—fixing equipment after it fails—or preventive maintenance, which is performed at regular intervals regardless of the equipment’s condition. While preventive maintenance can help avoid some failures, it often leads to unnecessary maintenance activities, wasting time and resources.

With IoT-driven proactive maintenance, businesses can shift to a condition-based maintenance approach, where maintenance activities are triggered only when specific performance thresholds are reached. This strategy not only prevents unnecessary maintenance but also reduces the risk of over-maintenance, which can sometimes do more harm than good. By focusing resources on equipment that truly needs attention, companies can optimize their maintenance budgets and reduce overall operational costs.

In sectors like manufacturing and logistics, where margins can be tight, the ability to cut maintenance costs without compromising reliability is a significant advantage. For instance, in a manufacturing plant, IoT sensors can monitor the performance of critical machinery such as conveyor belts, motors, and bearings. If a sensor detects that a component is nearing the end of its useful life, maintenance can be scheduled before a failure occurs, preventing costly disruptions and extending the life of the equipment.

Enhancing Resource Allocation and Efficiency

Another key benefit of is the enhancement of resource allocation and operational efficiency. By utilizing real-time data and analytics, businesses can better allocate their maintenance resources, ensuring that technicians and spare parts are available when and where they are needed most. This level of precision in resource management leads to more efficient operations, as maintenance teams can focus on tasks that will have the most significant impact on equipment performance and longevity.

In regions like Saudi Arabia and the UAE, where industries are rapidly expanding and the demand for skilled labor is high, efficient resource allocation is crucial for maintaining competitive advantage. IoT-enabled maintenance systems can help companies manage their workforce more effectively by providing detailed insights into the condition of their assets. This allows for more accurate planning of maintenance activities, reducing the likelihood of emergency repairs that require additional manpower and resources.

Furthermore, IoT-driven maintenance strategies can improve the overall efficiency of supply chains by reducing the risk of equipment failures that might delay production or transportation. In industries such as logistics, where timely delivery is critical, minimizing downtime through proactive maintenance can significantly enhance customer satisfaction and business reputation. By investing in IoT technology, companies can ensure that their operations run smoothly, even in the face of challenges such as equipment aging and increased demand.

Conclusion

In conclusion, are revolutionizing the way businesses manage their assets, offering significant benefits in terms of minimizing unplanned downtime, optimizing costs, and enhancing resource allocation. As industries in regions like Saudi Arabia and the UAE continue to grow, the adoption of IoT-driven maintenance approaches will be essential for maintaining operational efficiency and competitiveness. By leveraging the power of IoT technology, companies can proactively address potential issues, ensuring that their operations remain resilient, cost-effective, and reliable.

—

#IoTMaintenanceStrategies, #ProactiveMaintenance, #PredictiveMaintenance, #IoTInSaudiArabia, #IoTInUAE, #OperationalEfficiency, #CostSavingIoTSolutions