The Role of Nano-enhanced Lubricants in Machinery Performance

Introduction to Nano-enhanced Lubricants

Nano-enhanced lubricants have emerged as a game-changer in machinery maintenance, offering unparalleled benefits in reducing friction and wear. This revolutionary technology is reshaping the way industries approach equipment maintenance, with significant implications for businesses in Saudi Arabia and the UAE. The focus keyword, Nano-enhanced Lubricants, underscores the transformative impact of this innovation.

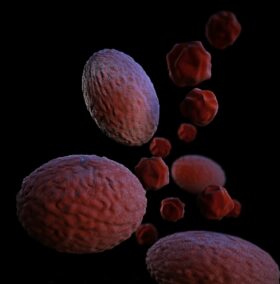

Traditional lubricants often struggle to provide adequate protection against friction and wear, especially in high-stress environments. Nano-enhanced lubricants address this challenge by incorporating nanomaterials that form a protective layer on machinery surfaces. This layer reduces friction and minimizes wear, resulting in extended equipment lifespan and improved performance. In regions like Saudi Arabia and the UAE, where machinery is subjected to extreme conditions, nano-enhanced lubricants offer a cost-effective solution for enhancing reliability and efficiency.

The adoption of nano-enhanced lubricants represents a paradigm shift in machinery maintenance practices. Businesses are increasingly recognizing the value of proactive maintenance strategies that prioritize longevity and performance. By investing in advanced lubrication technologies, companies can minimize downtime, reduce maintenance costs, and maximize the return on their equipment investments.

Executive Coaching and Effective Communication in Technology Adoption

The successful implementation of nano-enhanced lubricants requires effective leadership and communication within organizations. Executive coaching services play a crucial role in preparing leaders to navigate technological change and drive adoption initiatives. In Saudi Arabia and the UAE, executive coaching programs focused on technology adoption help leaders develop the skills and mindset needed to embrace innovation and manage change effectively.

Effective communication is also essential for ensuring buy-in and cooperation from stakeholders across the organization. Clear and transparent communication about the benefits of nano-enhanced lubricants fosters acceptance and enthusiasm for the new technology. Management consulting firms specializing in technology integration provide valuable support in developing communication strategies that resonate with employees at all levels.

By prioritizing executive coaching and effective communication, businesses can overcome resistance to change and facilitate a smooth transition to nano-enhanced lubricants. Strong leadership and clear communication create a conducive environment for innovation, empowering employees to embrace new technologies and drive organizational success.

The Future of Machinery Maintenance: AI, Blockchain, and The Metaverse

Looking ahead, the future of machinery maintenance will be shaped by advancements in Artificial Intelligence (AI), Blockchain, and The Metaverse. AI-powered predictive maintenance systems can anticipate equipment failures before they occur, optimizing maintenance schedules and reducing downtime. Blockchain technology ensures transparency and traceability in maintenance processes, while The Metaverse offers new opportunities for remote monitoring and maintenance.

The integration of these technologies with nano-enhanced lubricants holds the promise of even greater efficiency and reliability in machinery maintenance. Saudi Arabia and the UAE are at the forefront of exploring these possibilities, leveraging their technological expertise and strategic partnerships to drive innovation in the maintenance sector. By embracing emerging technologies and investing in research and development, businesses can stay ahead of the curve and maintain a competitive edge in the global market.

Maximizing the Benefits of Nano-enhanced Lubricants

To maximize the benefits of nano-enhanced lubricants, businesses should prioritize regular maintenance schedules and monitor equipment performance closely. Proactive maintenance practices, combined with advanced lubrication technologies, can significantly extend the lifespan of machinery and reduce overall operating costs.

Furthermore, ongoing research and development in nanotechnology are likely to yield even more advanced lubrication solutions in the future. By staying abreast of technological advancements and embracing innovation, businesses can stay competitive and resilient in an increasingly dynamic market.

In summary, nano-enhanced lubricants offer a promising solution for improving machinery performance and reducing maintenance costs. By embracing this technology and investing in the necessary support and infrastructure, businesses can achieve sustainable success in the long run.

Conclusion: Embracing Innovation for Sustainable Machinery Performance

In conclusion, nano-enhanced lubricants represent a breakthrough in machinery maintenance, offering superior protection against friction and wear. In Saudi Arabia and the UAE, where industries rely heavily on machinery, this technology is driving efficiency and sustainability. With the support of executive coaching, effective communication, and strategic investments in technology, businesses can unlock the full potential of nano-enhanced lubricants and ensure the long-term performance of their equipment.

As we look towards the future, the integration of AI, Blockchain, and The Metaverse will further enhance the capabilities of machinery maintenance. By embracing these advancements and fostering a culture of innovation, businesses can stay ahead in an ever-evolving landscape. The journey towards sustainable machinery performance begins with the adoption of nano-enhanced lubricants—a journey that promises to revolutionize maintenance practices and drive business success.

#NanoEnhancedLubricants #MachineryMaintenance #SaudiArabia #UAE #TechnologyInnovation #ExecutiveCoaching #EffectiveCommunication #AI #Blockchain #TheMetaverse #LeadershipSkills #ProjectManagement