How Companies Overcome Challenges in Deploying IoT-Based Predictive Maintenance Solutions

Identifying and Addressing Key Challenges in IoT-Based Predictive Maintenance

The journey of overcoming challenges in IoT-based predictive maintenance solutions is a crucial step for companies aiming to enhance operational efficiency and reduce maintenance costs. As industries in Saudi Arabia and the UAE increasingly adopt IoT technologies to predict equipment failures before they occur, they often face a set of challenges that require strategic planning and robust solutions. These challenges can range from data integration issues to cybersecurity concerns, but overcoming them is essential for the successful deployment of predictive maintenance systems.

In Dubai, a company specializing in manufacturing faced significant hurdles when implementing IoT-based predictive maintenance. The primary challenge was integrating diverse data sources from various machines that had been in operation for decades. These legacy systems were not initially designed to communicate with modern IoT sensors, creating a significant barrier to data collection and analysis. To address this, the company invested in IoT gateways that acted as intermediaries, converting the data from older equipment into formats compatible with newer analytical tools. This approach allowed the company to create a unified platform where data from all machines could be analyzed, providing valuable insights into equipment health and performance.

Another critical challenge encountered was ensuring the accuracy and reliability of the predictive algorithms. With vast amounts of data generated by IoT sensors, the quality of the input data directly impacts the effectiveness of the predictive models. In Riyadh, a logistics company addressed this by implementing stringent data validation processes, filtering out anomalies and ensuring that only high-quality data was used for analysis. By continuously refining their algorithms and incorporating feedback loops, they managed to enhance the precision of their predictive maintenance system, leading to more accurate forecasts of equipment failures and optimized maintenance schedules.

Building a Robust IoT Infrastructure for Predictive Maintenance

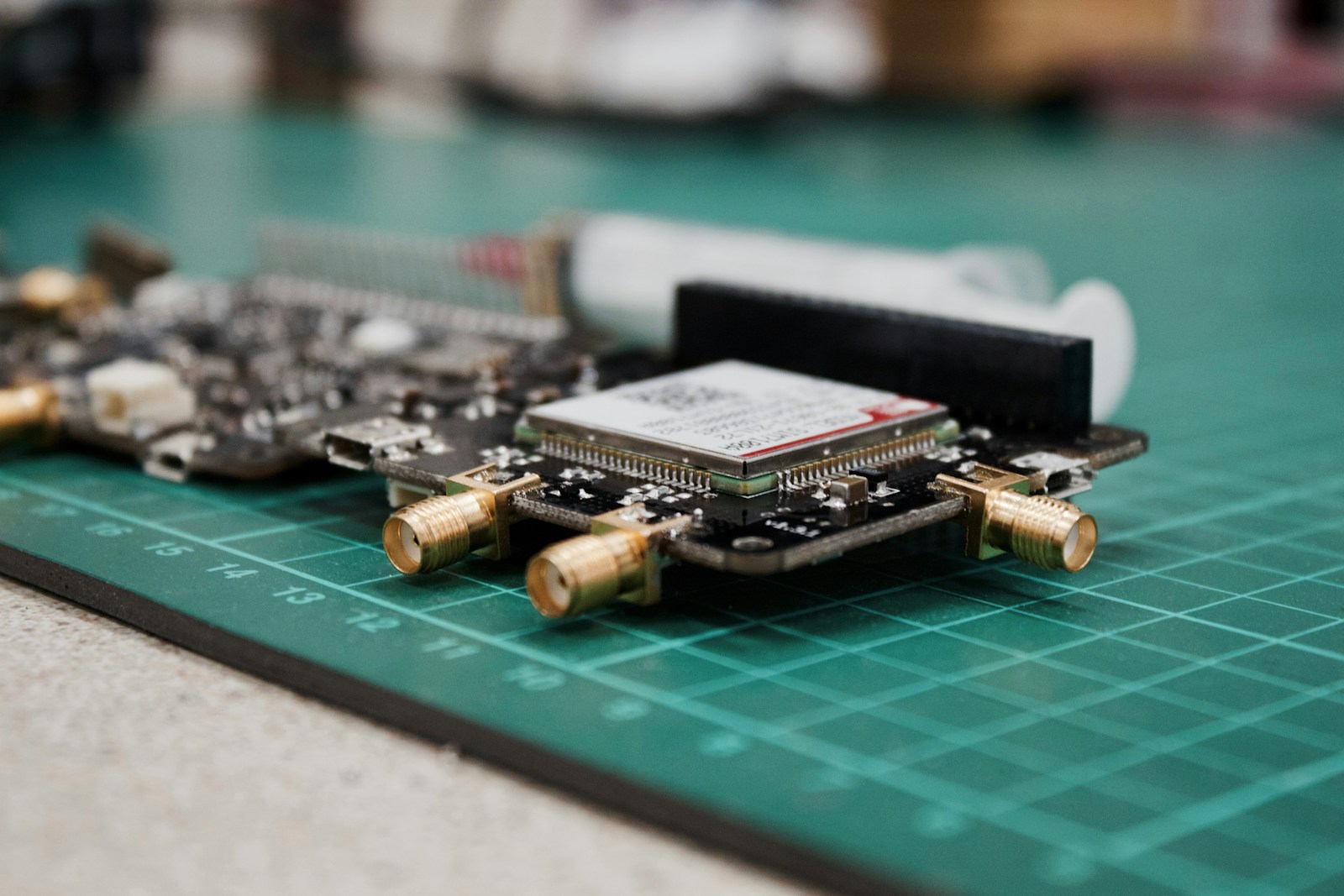

A key aspect of overcoming challenges in IoT-based predictive maintenance solutions lies in building a robust and scalable IoT infrastructure. For many companies, the deployment of predictive maintenance solutions requires significant investment in hardware, software, and human resources. In Saudi Arabia, a major oil and gas company embarked on this journey by first assessing its existing infrastructure and identifying areas that needed upgrading. They found that their legacy network was not equipped to handle the high volume of data generated by IoT sensors, leading to connectivity issues and data loss.

To overcome this, the company implemented a dedicated IoT network with enhanced bandwidth and low latency, ensuring that data from remote locations could be transmitted to central servers without interruptions. Additionally, they deployed edge computing devices to process data locally at the equipment level, reducing the reliance on centralized cloud servers and improving response times. This approach not only enhanced the reliability of their predictive maintenance system but also provided real-time insights that allowed maintenance teams to act swiftly and prevent equipment failures.

Cybersecurity is another critical component of a robust IoT infrastructure. As predictive maintenance solutions rely on vast networks of connected devices, protecting these systems from cyber threats is paramount. In Dubai, a manufacturing company strengthened its cybersecurity posture by implementing multi-layered security measures, including encryption, access controls, and continuous monitoring. They also conducted regular security audits and employee training sessions to ensure that all stakeholders understood the importance of cybersecurity in IoT deployments. By taking a proactive approach to security, the company was able to mitigate risks and protect its predictive maintenance system from potential cyberattacks.

Leveraging Data Analytics and AI for Enhanced Predictive Maintenance

Another significant aspect of overcoming challenges in IoT-based predictive maintenance solutions is leveraging advanced data analytics and artificial intelligence. While the initial implementation of IoT sensors and data collection infrastructure is critical, the true value of predictive maintenance lies in the ability to analyze data effectively and generate actionable insights. In Riyadh, a telecommunications company faced challenges with the sheer volume of data generated by its predictive maintenance system. The data, although valuable, was often unstructured and overwhelming, making it difficult to extract meaningful insights.

To address this, the company turned to AI-driven analytics platforms that could process large datasets and identify patterns indicative of potential equipment failures. By using machine learning algorithms, the company’s predictive maintenance system was able to learn from historical data and continuously improve its accuracy. This approach not only enhanced the predictive capabilities of the system but also allowed the company to transition from a reactive to a proactive maintenance strategy, significantly reducing downtime and maintenance costs.

Furthermore, collaboration with external partners and stakeholders proved to be a valuable strategy for enhancing predictive maintenance outcomes. In Dubai, a logistics company partnered with a technology provider specializing in IoT analytics to co-develop customized solutions tailored to their specific needs. This collaboration allowed the company to access cutting-edge technologies and expertise that would have been difficult to develop internally. By leveraging the strengths of external partners, the company was able to overcome technical challenges more effectively and accelerate the deployment of its predictive maintenance system.

Developing a Sustainable Predictive Maintenance Strategy

To ensure long-term success in overcoming challenges in IoT-based predictive maintenance solutions, companies must develop a sustainable strategy that includes continuous improvement and scalability. A key consideration is the alignment of predictive maintenance initiatives with broader organizational goals, such as sustainability, efficiency, and digital transformation. In Saudi Arabia, a large manufacturing company recognized the need to align its predictive maintenance efforts with its sustainability objectives, particularly in reducing energy consumption and minimizing waste.

The company implemented a feedback loop mechanism where the results of the predictive maintenance system were regularly reviewed and adjusted based on performance metrics. This continuous improvement approach allowed the company to refine its maintenance processes over time, ensuring that they remained effective and aligned with changing operational needs. Additionally, the company explored opportunities to scale its predictive maintenance solutions across multiple facilities, leveraging a standardized approach that could be replicated and adapted to different environments.

Training and stakeholder engagement also play a critical role in sustaining predictive maintenance initiatives. In Dubai, a construction firm invested in training programs for its maintenance teams to ensure they were well-versed in the new IoT technologies and could effectively use the predictive maintenance tools at their disposal. By fostering a culture of innovation and continuous learning, the company was able to build a resilient workforce capable of adapting to the evolving demands of predictive maintenance. This approach not only improved the efficacy of the system but also empowered employees to contribute to the company’s broader digital transformation goals.

Conclusion: The Path Forward for IoT-Based Predictive Maintenance

The journey of overcoming challenges in IoT-based predictive maintenance solutions is complex but rewarding, offering companies the opportunity to enhance their operational efficiency, reduce costs, and improve overall equipment reliability. By addressing key challenges such as data integration, infrastructure development, cybersecurity, and analytics, companies in Saudi Arabia, the UAE, and beyond can unlock the full potential of predictive maintenance and position themselves as leaders in their respective industries.

As IoT technology continues to evolve, the potential for predictive maintenance solutions will only expand, offering new opportunities for innovation and growth. For business executives, mid-level managers, and entrepreneurs, understanding the strategies for overcoming challenges in IoT-based predictive maintenance is essential for driving success in today’s competitive landscape. By investing in the right technologies, building robust infrastructures, and fostering a culture of continuous improvement, companies can turn challenges into opportunities and achieve long-term success in their predictive maintenance initiatives.

—

#IoTBasedPredictiveMaintenance #OvercomingChallenges #SmartMaintenance #DigitalTransformation #SaudiArabiaTech #UAETechnology #PredictiveMaintenanceSolutions #DubaiTech #RiyadhInnovation #IoTSolutions