Connecting IoT Solutions with Production Line Systems

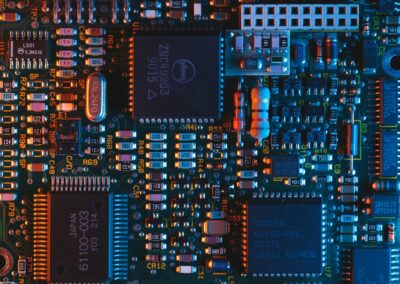

Understanding the Integration Challenges

Automotive Manufacturing embarks on integrating IoT solutions with its production line systems, several complex challenges often arise. These challenges stem from the need to ensure seamless communication between legacy systems and new IoT technologies. In regions like Saudi Arabia and the UAE, where automotive industries are rapidly advancing, manufacturers must address issues related to data compatibility, real-time data processing, and system interoperability. The integration process requires careful planning and execution to avoid disruptions in the production line and to ensure that all systems work harmoniously.

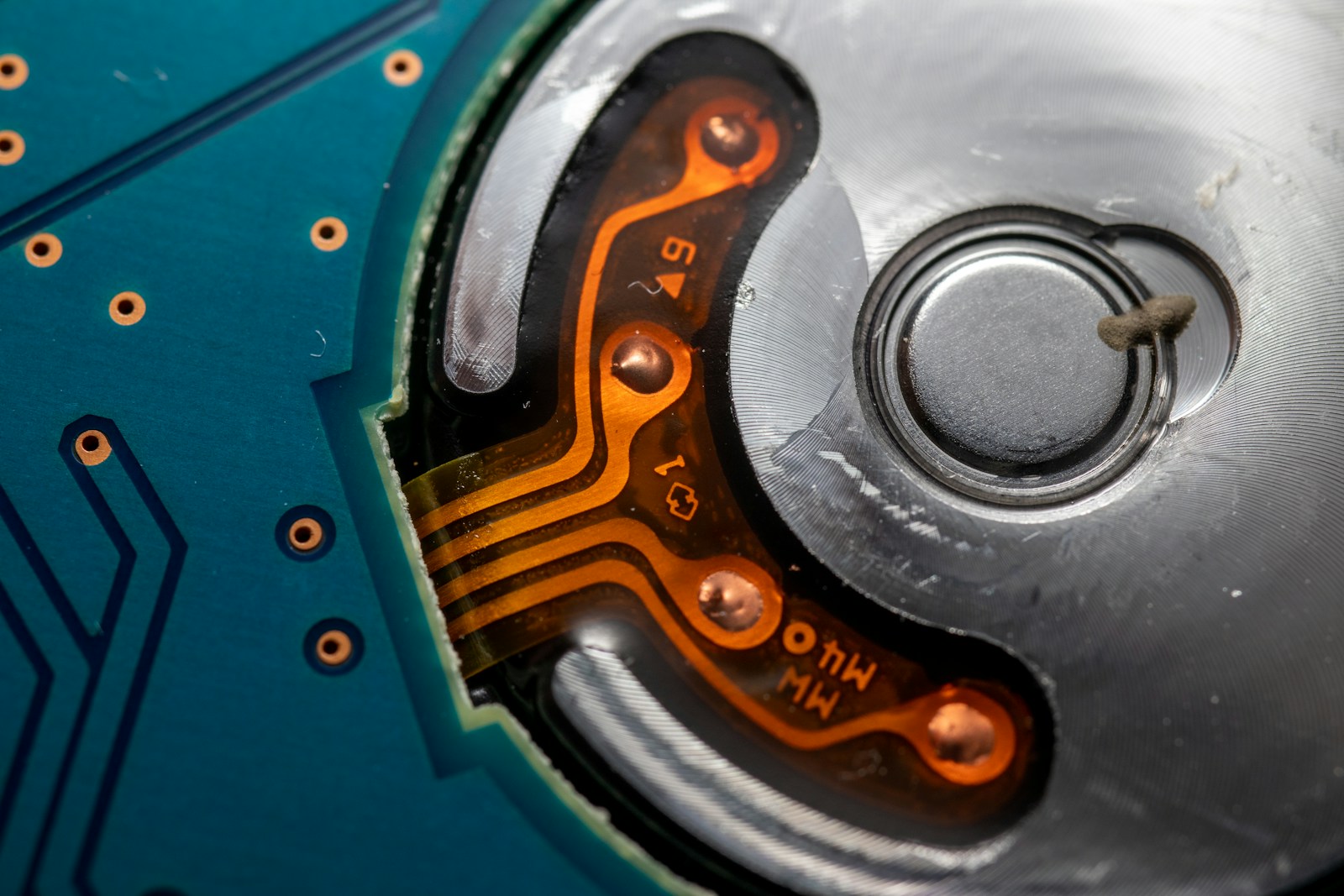

Implementing Advanced IoT Technologies

The successful integration of IoT solutions in automotive manufacturing involves leveraging advanced technologies to streamline operations. For instance, IoT sensors can be deployed across the production line to monitor equipment performance and predict maintenance needs. This real-time data collection and analysis enable manufacturers in Riyadh and Dubai to minimize downtime and optimize production efficiency. Additionally, integrating IoT with existing systems allows for better inventory management and quality control, ensuring that vehicles meet high standards before reaching the market.

Case Study: Overcoming Integration Challenges

One notable case study involves a leading automotive manufacturer that successfully integrated IoT solutions with its production line. The company faced significant challenges related to data integration and system compatibility. By partnering with technology experts and utilizing middleware platforms, the manufacturer was able to bridge the gap between legacy systems and new IoT technologies. The implementation of a robust data transformation process ensured that data from IoT sensors could be seamlessly integrated into the company’s ERP systems, providing valuable insights into production performance and enabling more informed decision-making.

Strategic Approaches to IoT Integration

Leveraging AI and Machine Learning

Artificial intelligence and machine learning play a crucial role in enhancing IoT integration in the automotive industry. By analyzing large volumes of data generated by IoT sensors, AI algorithms can identify patterns and anomalies, providing manufacturers with predictive insights. This capability is particularly valuable in regions like Saudi Arabia and the UAE, where maintaining high production standards is essential. AI-driven analytics enable manufacturers to optimize production processes, improve quality control, and reduce operational costs by predicting and preventing potential issues before they occur.

Ensuring Data Security and Compliance

Data security and compliance are paramount when integrating IoT solutions in automotive manufacturing. As IoT devices collect sensitive data, manufacturers must implement stringent security measures to protect this information from cyber threats. Ensuring compliance with local and international data protection regulations is also critical. For businesses in Riyadh and Dubai, adhering to these regulations not only mitigates legal risks but also builds trust with customers and stakeholders. By implementing robust encryption protocols and access controls, manufacturers can safeguard their IoT data and maintain compliance with relevant standards.

Driving Innovation and Business Success

The successful integration of IoT solutions in automotive manufacturing can drive significant innovation and business success. By leveraging real-time data and advanced analytics, manufacturers can enhance operational efficiency, reduce costs, and improve product quality. This is particularly important in competitive markets like Saudi Arabia and the UAE, where staying ahead of the curve is crucial. IoT integration enables manufacturers to respond quickly to market demands, streamline supply chain operations, and deliver high-quality vehicles that meet customer expectations. Ultimately, embracing IoT technologies positions automotive manufacturers for long-term success and growth in the digital age.

Conclusion: The Future of IoT Integration in Automotive Manufacturing

Overcoming the challenges of IoT integration in automotive manufacturing requires a strategic approach and a commitment to leveraging advanced technologies. By addressing data compatibility issues, ensuring data security, and utilizing AI-driven insights, manufacturers can achieve seamless integration of IoT solutions with their production line systems. This integration not only enhances operational efficiency but also drives innovation and business success. As automotive industries in Saudi Arabia, the UAE, Riyadh, and Dubai continue to evolve, the role of IoT integration will become increasingly critical in maintaining competitive advantage and achieving sustainable growth. By investing in robust IoT integration strategies, manufacturers can unlock new opportunities for innovation and excellence in the automotive sector.

—

#IoTIntegration #AutomotiveManufacturing #IntegrationChallenges #SaudiArabia #UAE #Riyadh #Dubai #ArtificialIntelligence #Blockchain #GenerativeAI #BusinessSuccess #LeadershipSkills #ProjectManagement