Driving Efficiency and Innovation in Aviation

Introduction to Additive Manufacturing and Novel Materials

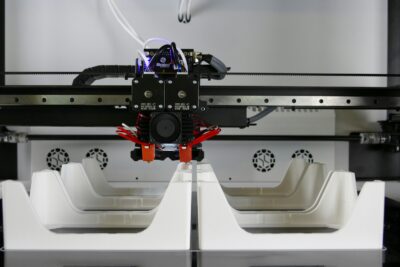

The aerospace industry is undergoing a transformation with the adoption of additive manufacturing and novel materials, allowing for the fabrication of complex aerodynamic shapes with reduced weight and production costs. In Saudi Arabia and the UAE, where the aviation sector is thriving, the integration of these technologies is revolutionizing aircraft design and manufacturing processes. This article explores the role of additive manufacturing and novel materials in driving efficiency and innovation in aviation, propelling the industry towards a more sustainable and competitive future.

Enhancing Aerodynamic Performance

Additive manufacturing enables engineers to create intricate geometries and complex structures that were previously impossible with traditional manufacturing methods. By layering materials and building up components layer by layer, additive manufacturing allows for the fabrication of aerodynamic shapes that optimize airflow and reduce drag. Moreover, novel materials such as carbon fiber composites and advanced polymers offer superior strength-to-weight ratios, further enhancing aerodynamic performance. In Riyadh and Dubai, where aerospace engineering is at the forefront of technological innovation, the adoption of these advanced manufacturing techniques is driving significant advancements in aircraft design and efficiency.

Reducing Weight and Production Costs

One of the primary advantages of additive manufacturing and novel materials is the ability to reduce the weight of aircraft components while maintaining structural integrity. Lighter aircraft consume less fuel, resulting in lower operating costs and reduced environmental impact. Additionally, additive manufacturing processes are inherently more efficient than traditional subtractive methods, leading to reduced material waste and lower production costs. By leveraging these technologies, aerospace manufacturers in Saudi Arabia and the UAE can produce aircraft more quickly and affordably, enhancing their competitiveness in the global market. This shift towards lightweight, cost-effective manufacturing is essential for driving business success and sustaining long-term growth in the aviation industry.

Conclusion: The Future of Aerospace Innovation

The adoption of additive manufacturing and novel materials marks a significant milestone in the evolution of aerospace technology. By enabling the fabrication of complex aerodynamic shapes with reduced weight and production costs, these technologies are reshaping the future of aviation. In Saudi Arabia and the UAE, where ambitious aerospace initiatives are driving economic diversification and technological advancement, additive manufacturing and novel materials play a central role in achieving these goals. As the industry continues to embrace innovation and efficiency, the possibilities for aerospace engineering are limitless. By investing in research, talent development, and infrastructure, these nations can position themselves as leaders in the global aerospace market, driving business success and contributing to the advancement of aviation technology.

The future of aerospace lies in the continuous advancement of additive manufacturing and novel materials, unlocking new possibilities for efficiency, performance, and sustainability. With a commitment to innovation and collaboration, Saudi Arabia and the UAE are poised to lead the way towards a brighter future in aviation.

As additive manufacturing and novel materials continue to evolve, their impact on the aerospace industry will only grow. By embracing these technologies and fostering a culture of innovation, businesses can stay ahead of the curve and thrive in the rapidly changing aerospace landscape.

—

#AdditiveManufacturing #NovelMaterials #AerodynamicShapes #AviationTechnology #AerospaceEngineering #SaudiArabia #UAE #Riyadh #Dubai #MaterialsInnovation #ModernTechnology