Maximizing Efficiency with IoT Solutions for Predictive Maintenance

In the competitive business landscapes of Saudi Arabia and the UAE, the adoption of IoT solutions for predictive maintenance is revolutionizing maintenance practices, ensuring operational efficiency and cost savings. These advanced technologies utilize sensor data and analytics to predict equipment failures before they occur, thereby reducing downtime and maintenance costs. In cities like Riyadh and Dubai, where businesses strive for continuous improvement, IoT-enabled predictive maintenance provides a strategic advantage by allowing proactive maintenance interventions. By leveraging real-time data insights, organizations can optimize equipment performance, minimize disruptions, and enhance overall productivity, thus maintaining a competitive edge in the market.

Executive Coaching and Change Management for Successful Implementation

Implementing IoT solutions for predictive maintenance requires effective change management and executive coaching to ensure successful integration and utilization. Business executives and mid-level managers in Riyadh and Dubai can benefit from tailored coaching programs that enhance their understanding of IoT technologies and their applications in maintenance operations. Executive coaching helps leaders develop the skills necessary to oversee technological transitions and drive organizational change. Change management strategies are essential for aligning stakeholders with new technological advancements, fostering a culture of innovation and adaptability within the organization. This approach ensures smooth implementation and maximizes the benefits of predictive maintenance solutions.

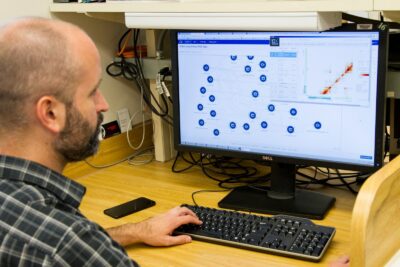

Effective Communication and Management Consulting for Maintenance Success

Effective communication and strategic management consulting play a crucial role in the successful deployment of IoT solutions for predictive maintenance. Clear communication channels help in educating maintenance teams about the functionalities and benefits of IoT-enabled predictive maintenance technologies. In regions like Riyadh and Dubai, management consulting firms offer expertise in integrating these systems into existing maintenance practices. Consultants provide insights on optimizing maintenance schedules, improving equipment reliability, and reducing operational costs through IoT solutions. Professional guidance ensures that businesses not only adopt predictive maintenance effectively but also achieve long-term improvements in asset performance and maintenance efficiency.

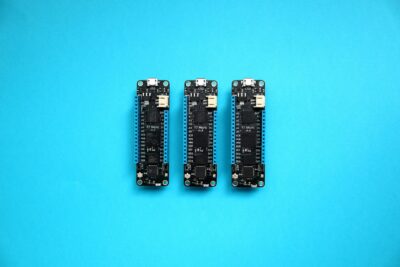

Technological Innovations Driving Predictive Maintenance

The integration of Artificial Intelligence (AI) with IoT solutions is driving significant advancements in predictive maintenance. AI enhances the capabilities of IoT devices by providing predictive analytics, anomaly detection, and automated decision-making. In the dynamic business environments of Riyadh and Dubai, AI-driven IoT solutions enable organizations to anticipate equipment failures, prioritize maintenance tasks, and optimize resource allocation. This synergy between AI and IoT empowers businesses to transition from reactive to proactive maintenance strategies, reducing downtime and improving asset reliability. The use of AI in predictive maintenance not only enhances operational efficiency but also supports business growth and sustainability.

Blockchain and the Metaverse: Future Prospects

Emerging technologies like Blockchain and the Metaverse offer new possibilities for enhancing predictive maintenance practices. Blockchain technology can enhance the security and transparency of maintenance data, ensuring the integrity of equipment maintenance records and service history. In forward-thinking business sectors like those in Riyadh and Dubai, the adoption of Blockchain can streamline maintenance processes and increase trust among stakeholders. The Metaverse, on the other hand, offers innovative opportunities for immersive maintenance experiences. By integrating IoT solutions within virtual maintenance environments, businesses can visualize equipment performance data, simulate maintenance scenarios, and train maintenance personnel more effectively, thus driving continuous improvement in maintenance operations.

Generative AI and Leadership Skills Development

Generative AI is poised to transform leadership development and strategic planning in predictive maintenance. This technology can generate advanced models and simulations for optimizing maintenance operations and predicting equipment failures. In the evolving business landscapes of Riyadh and Dubai, leaders can leverage Generative AI to develop more effective strategies for implementing and managing IoT technologies in maintenance operations. Additionally, Generative AI supports leadership skills development by offering personalized coaching experiences and data-driven insights, ensuring that executives and managers are well-equipped to lead in the era of predictive maintenance and digital transformation. As businesses continue to evolve, the integration of Generative AI in IoT solutions will be crucial for maintaining a competitive edge and achieving long-term success in predictive maintenance.

#IoT #PredictiveMaintenance #SensorData #Analytics #EquipmentFailures #SaudiArabia #UAE #Riyadh #Dubai #ChangeManagement #ExecutiveCoaching #EffectiveCommunication #BusinessSuccess #ManagementConsulting #ArtificialIntelligence #Blockchain #Metaverse #GenerativeAI #LeadershipSkills #ProjectManagement