Driving Efficiency and Innovation in Industrial Automation

In today’s competitive landscape, industries across Saudi Arabia and the UAE are increasingly turning to IoT solutions for industrial automation to streamline operations, enhance productivity, and gain a competitive edge in the global market. By leveraging IoT-enabled sensors, actuators, and data analytics platforms, businesses can optimize production processes, minimize downtime, and maximize output efficiency. From manufacturing plants in Riyadh to logistics facilities in Dubai, IoT technologies enable real-time monitoring and control of equipment, allowing for predictive maintenance, proactive interventions, and continuous process optimization. By harnessing the power of IoT-driven automation, businesses can achieve higher levels of operational efficiency, reduce production costs, and deliver superior products and services to customers.

Improving Quality Control

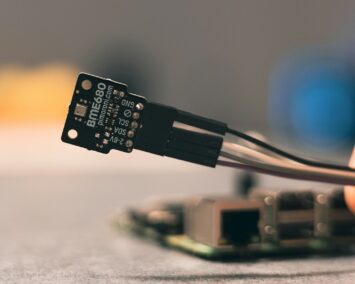

Moreover, IoT solutions play a crucial role in quality control processes, enabling businesses to monitor product quality, detect defects, and ensure compliance with industry standards and regulations. By integrating IoT sensors into production lines and supply chain networks, businesses can track key performance indicators, collect real-time data on product characteristics, and identify potential issues before they escalate. Whether it’s monitoring temperature, humidity, or pressure levels in manufacturing environments, IoT-driven quality control systems provide unprecedented visibility and insights into production processes, enabling businesses to identify areas for improvement, reduce defects, and deliver consistently high-quality products to customers. With IoT solutions for quality control, businesses can enhance brand reputation, increase customer satisfaction, and gain a competitive advantage in the marketplace.

Reducing Costs Through Real-Time Monitoring

Furthermore, IoT solutions enable businesses to reduce costs and improve resource utilization through real-time monitoring and optimization of equipment and assets. By deploying IoT sensors and connected devices throughout industrial facilities, businesses can gather data on equipment performance, energy consumption, and resource utilization, allowing for data-driven decision-making and proactive maintenance strategies. From predictive analytics algorithms that forecast equipment failures to automated control systems that optimize energy usage, IoT-driven cost reduction initiatives help businesses minimize waste, lower operational expenses, and improve overall profitability. With IoT solutions for industrial automation, businesses can unlock new opportunities for growth, innovation, and sustainability, positioning themselves for long-term success in the ever-evolving global marketplace.

Enhancing Operational Visibility

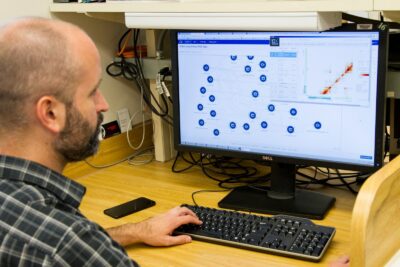

In addition to optimizing production processes and improving quality control, IoT solutions provide businesses with enhanced operational visibility and insights that drive strategic decision-making and innovation. By connecting disparate systems, devices, and processes across the supply chain, businesses can gain real-time visibility into inventory levels, demand patterns, and customer preferences, enabling more accurate forecasting, inventory management, and order fulfillment. With IoT-enabled asset tracking and monitoring capabilities, businesses can track the movement of goods, optimize routing and scheduling, and improve delivery performance, resulting in faster order fulfillment, reduced lead times, and increased customer satisfaction. By harnessing the power of IoT-driven operational insights, businesses can identify opportunities for process improvement, innovation, and differentiation, positioning themselves as industry leaders in the rapidly evolving marketplace.

Driving Sustainable Growth and Resilience

Furthermore, IoT solutions enable businesses to drive sustainable growth and resilience by optimizing resource utilization, minimizing environmental impact, and promoting operational efficiency. By leveraging IoT-enabled energy management systems, businesses can monitor and optimize energy consumption, reduce carbon emissions, and achieve sustainability goals, while also lowering operating costs and improving profitability. Additionally, IoT-driven predictive maintenance systems help businesses minimize equipment downtime, extend asset lifecycles, and reduce maintenance costs, ensuring continuity of operations and enhancing business resilience in the face of unforeseen disruptions. With IoT solutions for sustainability and resilience, businesses can build more agile, adaptive, and sustainable operations that thrive in today’s dynamic business environment.

Empowering Digital Transformation and Innovation

Moreover, IoT solutions empower businesses to embark on digital transformation journeys and drive innovation across all aspects of their operations. By integrating IoT technologies with other emerging technologies such as Artificial Intelligence and Blockchain, businesses can unlock new opportunities for automation, optimization, and value creation. Whether it’s leveraging AI-powered predictive analytics to optimize production schedules or using Blockchain-enabled smart contracts to streamline supply chain transactions, IoT-driven digital transformation initiatives enable businesses to reimagine processes, reinvent business models, and create new sources of competitive advantage.

#IoT #IndustrialAutomation #QualityControl #CostReduction #OperationalVisibility #Sustainability #DigitalTransformation #Innovation #SaudiArabia #UAE #Riyadh #Dubai #BusinessSuccess #ManagementConsulting