Nanotechnology: Transforming Adhesive and Sealant Performance

Introduction to Nanotechnology in Adhesives

In the realm of materials science, nanotechnology is driving significant advancements in the formulation and performance of adhesives and sealants. By leveraging the unique properties of nanomaterials, manufacturers can develop adhesives and sealants that offer enhanced bonding strength, durability, and versatility. This innovative approach to adhesive technology is revolutionizing industrial applications across diverse sectors, from construction and automotive to electronics and aerospace. In regions like Saudi Arabia and the UAE, where industries demand high-performance solutions, the integration of nanotechnology into adhesives and sealants is reshaping the landscape of materials engineering.

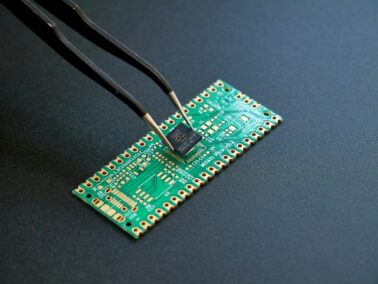

Nanotechnology has opened up new possibilities for enhancing the properties of adhesives and sealants, thanks to the exceptional characteristics of nanoparticles. These microscopic particles, typically ranging from 1 to 100 nanometers in size, exhibit unique mechanical, electrical, and chemical properties that differ from their bulk counterparts. When incorporated into adhesive formulations, nanoparticles can improve key attributes such as adhesion strength, thermal stability, and resistance to environmental factors. As a result, nanotechnology-enabled adhesives and sealants offer superior performance and reliability compared to conventional products, making them indispensable for critical applications in demanding environments.

The Advantages of Nanotechnology in Adhesives

The adoption of nanotechnology in adhesive manufacturing brings several advantages that address the evolving needs of industries and end-users. One of the primary benefits is the exceptional bonding strength provided by nanomaterials, which enable adhesives to form robust and durable bonds between various substrates. Whether bonding metals, plastics, ceramics, or composites, nanotechnology-enhanced adhesives ensure reliable adhesion under challenging conditions, including high temperatures, moisture, and mechanical stress. This level of performance is essential for applications where traditional adhesives may fail to meet the stringent requirements of modern manufacturing processes.

Furthermore, nanotechnology enables the development of adhesive formulations with tailored properties to suit specific applications and performance criteria. Manufacturers can precisely control the size, shape, and composition of nanoparticles to achieve desired outcomes, such as improved flexibility, chemical resistance, or conductivity. This customization capability empowers industries to optimize adhesive solutions for diverse applications, ranging from structural bonding and assembly to electronic packaging and medical device manufacturing. By leveraging nanotechnology, businesses can stay ahead of the competition and meet the evolving demands of their customers with innovative adhesive solutions that deliver unmatched performance and reliability.

Challenges and Future Prospects

Despite the significant advancements enabled by nanotechnology in adhesives, there are challenges that must be addressed to realize its full potential. One such challenge is the scalability and cost-effectiveness of nanoparticle production, especially for large-scale manufacturing applications. Manufacturers need to invest in research and development to optimize production processes and reduce the cost of nanomaterials, making them more accessible to industries across different sectors. Additionally, there is a need for standardization and regulation to ensure the safety and environmental sustainability of nanotechnology-enabled adhesives throughout their lifecycle.

Looking ahead, the future of nanotechnology in adhesives is promising, with ongoing research and innovation driving continuous improvements and new applications. As industries continue to demand high-performance adhesive solutions that meet stringent performance requirements, nanotechnology will play a crucial role in shaping the next generation of materials and manufacturing processes. In Saudi Arabia, the UAE, and beyond, businesses are embracing nanotechnology-enabled adhesives and sealants to enhance productivity, efficiency, and product quality across diverse sectors. With a focus on innovation and collaboration, nanotechnology is poised to redefine the boundaries of adhesive technology and drive progress towards a more sustainable and resilient future.

Conclusion: Pioneering Nanotechnology in Adhesives and Sealants

In conclusion, nanotechnology is revolutionizing the field of adhesives and sealants, offering unparalleled opportunities for enhancing performance, durability, and versatility. Through the precise manipulation of nanomaterials, manufacturers can develop adhesive formulations that meet the evolving needs of industries and applications. From improving bonding strength to enhancing resistance to environmental factors, nanotechnology-enabled adhesives and sealants are reshaping the landscape of materials engineering and industrial solutions. As businesses in Saudi Arabia, the UAE, and around the world embrace the potential of nanotechnology, the future holds exciting possibilities for innovation, collaboration, and sustainable development in the realm of adhesive technology.

—

#nanotechnology #adhesives #sealants #materialsscience #innovation #SaudiArabia #UAE #Riyadh #Dubai #industrialapplications