The Impact of Advanced Robotics and Automation in Manufacturing

The development of advanced robotics and automation has the potential to revolutionize manufacturing and other labor-intensive industries. In cities like Riyadh and Dubai, where innovation drives economic growth, integrating these technologies can significantly enhance productivity and efficiency. Advanced robotics and automation are reshaping the manufacturing landscape, offering unprecedented opportunities for business success and industrial transformation.

The integration of advanced robotics into manufacturing processes brings numerous benefits, including increased precision, speed, and cost-effectiveness. Robots can perform repetitive tasks with consistent accuracy, reducing the likelihood of human error. This results in higher quality products and fewer defects, which is crucial for maintaining competitive advantage in the global market. Automation also enables continuous production, minimizing downtime and maximizing output, which is essential for meeting the growing demands of industries in Saudi Arabia and the UAE.

Furthermore, automation and robotics can address the challenges of labor shortages in labor-intensive industries. By automating routine and physically demanding tasks, companies can allocate human resources to more strategic and creative roles. This not only enhances operational efficiency but also improves employee satisfaction and retention. As a result, businesses can attract and retain top talent, fostering a culture of innovation and growth.

Enhancing Business Success with Robotics and AI Integration

The integration of robotics and artificial intelligence (AI) in manufacturing is a game-changer for business success. AI-powered robots can analyze vast amounts of data in real-time, making informed decisions and optimizing production processes. This capability is particularly valuable in dynamic markets like those in Saudi Arabia and the UAE, where agility and responsiveness are key to staying ahead of the competition.

AI-driven robotics can also facilitate predictive maintenance, reducing equipment downtime and maintenance costs. By continuously monitoring the condition of machinery, AI systems can predict when maintenance is required and schedule it proactively, preventing unexpected breakdowns. This not only extends the lifespan of equipment but also ensures uninterrupted production, leading to significant cost savings and increased profitability.

Moreover, the use of advanced robotics and automation can support sustainability initiatives. AI-powered systems can optimize energy consumption, reduce waste, and minimize the environmental impact of manufacturing processes. This aligns with the sustainability goals of many businesses in the region, contributing to a greener and more sustainable future. As consumers and stakeholders increasingly prioritize sustainability, companies that leverage robotics and AI to enhance their environmental performance can gain a competitive edge.

Leadership and Management Skills for the Robotics Era

As advanced robotics and automation transform manufacturing, leadership and management skills must also evolve to keep pace with technological advancements. Business leaders in Riyadh, Dubai, and other innovation hubs need to develop a deep understanding of robotics and AI to effectively lead their organizations through this transformative era. This involves not only technical knowledge but also strategic vision and the ability to drive cultural change.

Executive coaching services can play a crucial role in helping leaders navigate the complexities of integrating robotics and automation into their businesses. Coaching programs can provide personalized guidance on leveraging technology to achieve strategic objectives, fostering a culture of innovation, and managing the human impact of automation. By developing these skills, leaders can ensure their organizations remain competitive and resilient in the face of technological disruption.

Additionally, project management skills are essential for successful robotics and automation initiatives. Implementing these technologies requires careful planning, coordination, and execution. Project managers need to manage cross-functional teams, oversee the integration of new systems, and ensure seamless collaboration between human workers and robots. Effective project management can mitigate risks, optimize resource allocation, and deliver successful outcomes, driving business success in the era of advanced robotics.

The Future of Manufacturing with Advanced Robotics and Automation

The future of manufacturing with advanced robotics and automation is promising, with transformative potential for industries in Saudi Arabia, the UAE, and beyond. As these technologies continue to evolve, they will drive significant advancements in productivity, efficiency, and innovation. Businesses that embrace robotics and automation can position themselves at the forefront of this industrial revolution, unlocking new opportunities for growth and success.

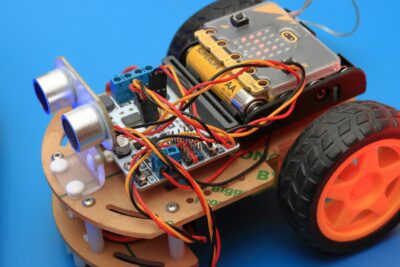

One of the key trends in the future of manufacturing is the rise of collaborative robots, or cobots. Unlike traditional industrial robots, which are designed to operate in isolation from human workers, cobots are engineered to work alongside humans, enhancing their capabilities and productivity. Cobots can assist with tasks that require precision and strength, such as assembly, packaging, and quality control. By working collaboratively with human workers, cobots can create a more flexible and adaptive manufacturing environment.

Another significant development is the use of digital twins in manufacturing. Digital twins are virtual replicas of physical assets, processes, or systems that use real-time data to simulate and optimize performance. In manufacturing, digital twins can model production lines, predict equipment failures, and optimize workflows. This technology enables businesses to experiment with different scenarios, identify potential improvements, and implement changes with minimal risk. The use of digital twins can lead to more efficient and resilient manufacturing operations.

Navigating the Ethical and Societal Implications

While the benefits of advanced robotics and automation are substantial, it is important to address the ethical and societal implications of these technologies. Automation has the potential to displace certain jobs, particularly those involving routine and manual tasks. Business leaders must consider the impact on their workforce and develop strategies to support employees through this transition. This may involve reskilling and upskilling programs to prepare workers for new roles in the automated workplace.

Ensuring the ethical use of robotics and AI is also critical. Businesses must adhere to ethical standards and regulations to protect worker safety, privacy, and data security. Transparent communication with employees and stakeholders about the benefits and risks of automation can build trust and support for these initiatives. By addressing ethical considerations proactively, businesses can navigate the complexities of automation responsibly and sustainably.

Conclusion: Embracing the Future of Manufacturing

In conclusion, the development of advanced robotics and automation is revolutionizing manufacturing and other labor-intensive industries. In regions like Saudi Arabia and the UAE, where innovation and technology are driving economic growth, embracing these advancements can lead to significant business success. By integrating robotics and AI, businesses can enhance productivity, improve sustainability, and gain a competitive edge.

However, navigating the ethical and societal implications of automation is crucial for responsible and sustainable implementation. Business leaders must develop the necessary skills, foster a culture of innovation, and address the human impact of automation. Through strategic leadership and effective project management, organizations can embrace the future of manufacturing with advanced robotics and automation, unlocking new opportunities for growth and innovation.

—

#AdvancedRobotics #Automation #Manufacturing #LaborIntensiveIndustries #AITechnology #UAE #SaudiArabia #Riyadh #Dubai #BusinessInnovation #LeadershipSkills #ProjectManagement #IndustrialRevolution #TechnologyAdvancement