Enhancing Efficiency and Productivity in Manufacturing

Optimizing Manufacturing Processes with IIoT Solutions

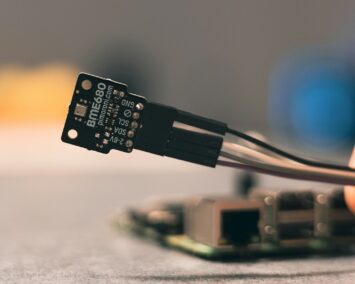

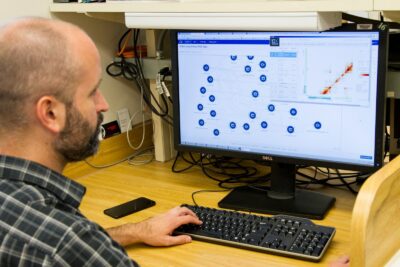

Industrial IoT (IIoT) solutions are revolutionizing manufacturing processes by providing real-time insights into equipment performance and predicting maintenance needs. In Saudi Arabia and the UAE, where manufacturing industries are thriving, IIoT technologies offer significant advantages in terms of efficiency, productivity, and cost-effectiveness. By leveraging sensors, data analytics, and connectivity, manufacturers can monitor critical equipment parameters, identify potential issues before they escalate, and proactively schedule maintenance activities. This proactive approach not only minimizes downtime but also extends the lifespan of machinery, resulting in substantial cost savings and improved operational efficiency.

Driving Business Success with IIoT Implementation

The successful implementation of IIoT solutions requires effective change management and strategic planning. Business executives and mid-level managers in Riyadh and Dubai must recognize the transformative potential of IIoT technologies and invest in the necessary infrastructure and training programs. Executive coaching services tailored to IIoT adoption can empower leadership teams to navigate the complexities of digital transformation and maximize the benefits of IIoT implementation. Additionally, management consulting firms specializing in IIoT can provide valuable insights and expertise to streamline the integration process and ensure alignment with organizational goals. By embracing IIoT solutions, businesses can position themselves for long-term success in the competitive manufacturing landscape.

Unlocking the Potential of Artificial Intelligence in Manufacturing

Artificial Intelligence (AI) plays a crucial role in enhancing the capabilities of IIoT solutions in manufacturing. AI-powered algorithms analyze vast amounts of sensor data to identify patterns, detect anomalies, and predict equipment failures with high accuracy. In Saudi Arabia and the UAE, manufacturers are increasingly incorporating AI into their IIoT systems to optimize production schedules, reduce waste, and improve product quality. By harnessing the power of AI-driven predictive maintenance, businesses can transition from reactive to proactive maintenance strategies, minimizing unplanned downtime and maximizing asset utilization. This proactive approach not only improves operational efficiency but also enhances overall business performance and competitiveness in the global market.

Embracing Sustainability in Manufacturing Processes

Industrial IoT solutions not only optimize manufacturing processes but also contribute to sustainability initiatives in Saudi Arabia and the UAE. By monitoring energy consumption, emissions, and resource utilization in real time, IIoT technologies enable manufacturers to identify areas for improvement and implement eco-friendly practices. Smart energy management systems, powered by IIoT sensors and AI algorithms, help reduce carbon footprints and minimize environmental impact. Additionally, blockchain technology can be integrated into IIoT networks to ensure transparency, traceability, and compliance with sustainability standards. By adopting sustainable manufacturing practices enabled by IIoT solutions, businesses can achieve economic growth while minimizing their environmental footprint.

Fostering Innovation through Collaboration and Integration

Collaboration and integration are key drivers of innovation in the realm of Industrial IoT solutions. In Riyadh and Dubai, manufacturers are partnering with technology providers, research institutions, and government agencies to develop cutting-edge IIoT applications tailored to their specific needs. Cross-industry collaborations facilitate the exchange of best practices, ideas, and resources, accelerating the pace of innovation and digital transformation. Furthermore, integrating IIoT with other emerging technologies such as blockchain and The Metaverse opens up new possibilities for data management, supply chain optimization, and immersive manufacturing experiences. By embracing a culture of innovation and collaboration, businesses can stay ahead of the curve and capitalize on the full potential of Industrial IoT solutions.

Maximizing Operational Efficiency with Predictive Maintenance

Predictive maintenance, enabled by Industrial IoT solutions, is revolutionizing maintenance practices in manufacturing facilities across Saudi Arabia and the UAE. By analyzing historical data, monitoring equipment conditions in real time, and leveraging machine learning algorithms, manufacturers can accurately predict when machinery is likely to fail and proactively schedule maintenance tasks. This approach minimizes the risk of unexpected breakdowns, reduces downtime, and extends the lifespan of critical assets. As a result, businesses can optimize their operational efficiency, increase productivity, and enhance overall profitability.

#IndustrialIoT #IIoTSolutions #Manufacturing #PredictiveMaintenance #BusinessSuccess #ChangeManagement #ExecutiveCoaching #ManagementConsulting #ArtificialIntelligence #Blockchain #Sustainability #Innovation #SaudiArabia #UAE #Riyadh #Dubai