Transforming Efficiency through IoT and Robotics in Manufacturing

Enhancing Operational Efficiency with IoT and Robotics

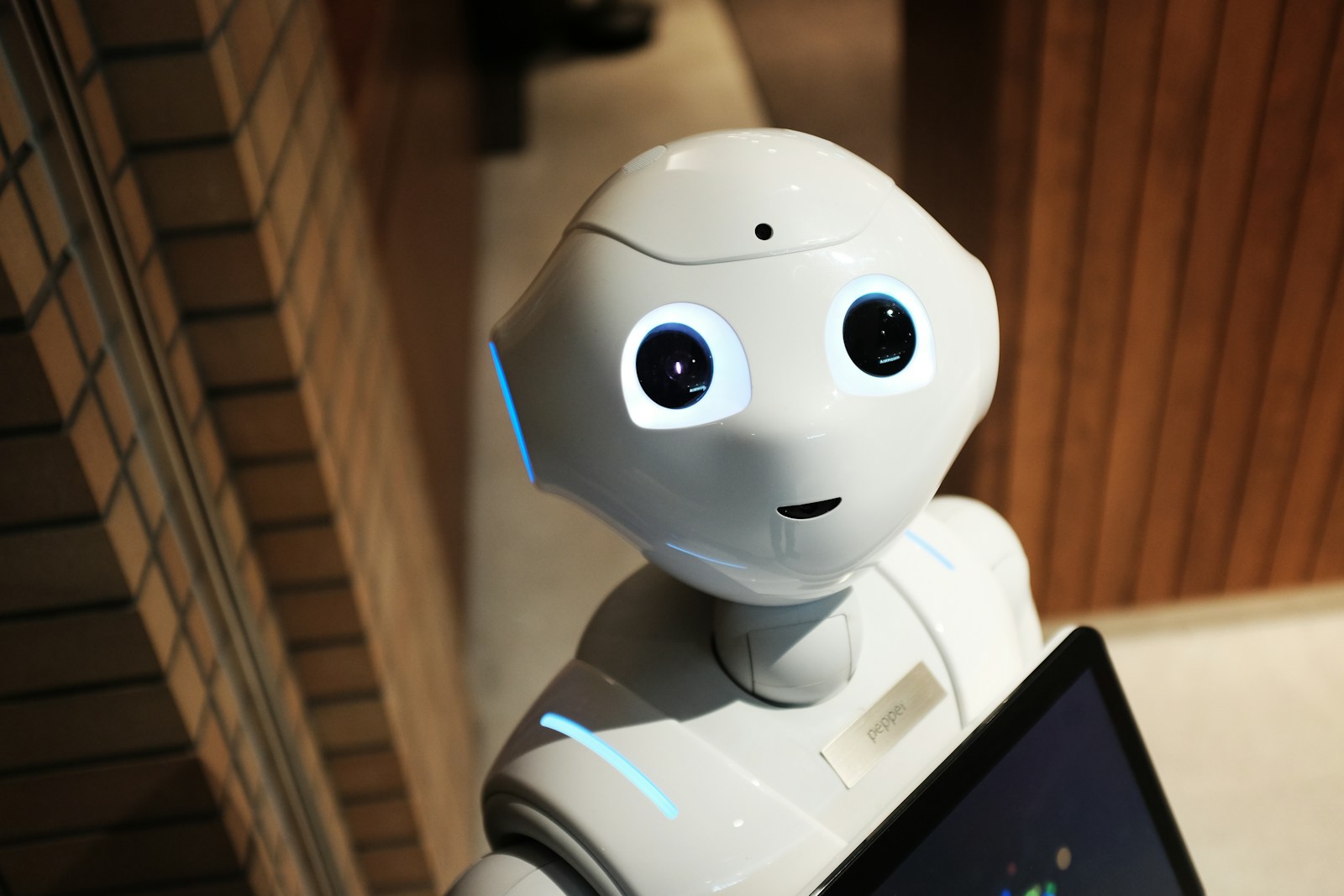

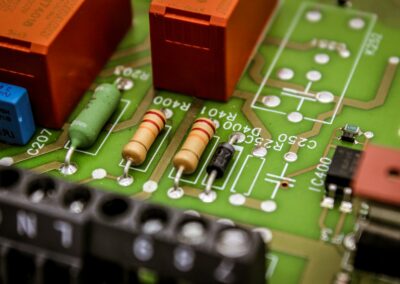

The integration of IoT and Robotics in Manufacturing has dramatically transformed operational efficiency across industries in regions such as Riyadh and Dubai. By combining advanced robotics with the Internet of Things (IoT), manufacturers have achieved unprecedented levels of automation and precision. IoT-enabled sensors embedded in robotic systems collect real-time data on machinery performance, enabling predictive maintenance and reducing downtime. This seamless integration allows for continuous monitoring and swift response to potential issues, thus optimizing production processes and enhancing overall efficiency. As a result, manufacturers in Saudi Arabia and the UAE have witnessed significant improvements in operational productivity and cost-effectiveness.

Boosting Automation and Reducing Human Error

One of the key benefits of integrating IoT with robotics is the substantial reduction in human error and increased automation. Robotics systems equipped with IoT capabilities can perform repetitive and complex tasks with high precision, minimizing the risk of errors associated with manual operations. This shift towards automation not only improves product quality but also accelerates production cycles. By leveraging advanced robotics and IoT technology, manufacturers in Dubai and Saudi Arabia are able to maintain consistent quality standards and meet increasing market demands more effectively. The enhanced automation capabilities have revolutionized the manufacturing sector, setting new benchmarks for operational excellence.

Optimizing Supply Chain and Production Processes

The synergy between IoT and robotics has also revolutionized supply chain and production processes. IoT devices provide real-time visibility into supply chain operations, allowing manufacturers to track inventory levels, manage logistics, and forecast demand with greater accuracy. When integrated with robotics, this real-time data facilitates more efficient production scheduling and inventory management. In Riyadh and Dubai, manufacturers are utilizing this integrated approach to streamline their supply chains, reduce lead times, and enhance the agility of their production processes. The result is a more responsive and resilient manufacturing ecosystem capable of adapting to dynamic market conditions.

Leadership and Strategic Implementation in IoT and Robotics

Strategic Leadership in IoT and Robotics Integration

Effective leadership is crucial for the successful integration of IoT and robotics in manufacturing. Business executives and project managers in Saudi Arabia and the UAE are embracing modern technologies to drive innovation and maintain a competitive edge. Strategic leadership involves not only the adoption of cutting-edge technologies but also the development of a clear vision and roadmap for implementation. Executive coaching services play a vital role in equipping leaders with the skills necessary to navigate the complexities of technological integration. By fostering a culture of innovation and encouraging cross-functional collaboration, leaders ensure that IoT and robotics initiatives align with broader business objectives and drive meaningful outcomes.

Project Management Best Practices for Technological Integration

Successful integration of IoT and robotics requires meticulous project management and adherence to best practices. Managers in Dubai and Riyadh are employing comprehensive planning, risk management, and execution strategies to ensure seamless deployment. Key aspects include setting clear objectives, allocating resources efficiently, and monitoring progress through regular evaluations. Utilizing modern project management tools and methodologies helps in addressing potential challenges and keeping projects on track. By implementing these best practices, manufacturers are able to achieve smooth integration of IoT and robotics, thereby enhancing operational efficiency and achieving their strategic goals.

Driving Business Success through Modern Technology

The integration of IoT and robotics in manufacturing not only improves operational efficiency but also contributes significantly to business success. Companies in Saudi Arabia and the UAE are leveraging these technologies to gain a competitive advantage and drive growth. The implementation of advanced robotics and IoT solutions results in enhanced product quality, reduced operational costs, and increased market responsiveness. Additionally, the insights gained from IoT data analytics enable continuous improvement and innovation. As businesses embrace modern technology, they position themselves for long-term success in an increasingly competitive global market. The strategic use of IoT and robotics is a testament to the potential of technological advancements to transform industries and drive sustainable growth.

—

#IoTAndRoboticsIntegration #AutomationInManufacturing #AdvancedRobotics #EfficiencyInManufacturing #SmartManufacturing #ArtificialIntelligence #Blockchain #GenerativeAI #ModernTechnology #LeadershipInTech #BusinessSuccess #ProjectManagement #SaudiArabia #UAE #Riyadh #Dubai