Ensuring a Smooth Transition from IoT Prototyping to Full-Scale Production

Understanding the Challenges of Moving from Prototype to Production

Strategies for transitioning IoT prototyping to production are crucial for ensuring the success of IoT projects in dynamic markets like Saudi Arabia and the UAE. The journey from an initial concept to a fully functional product is fraught with challenges that can hinder progress if not properly managed. In the prototyping phase, developers often focus on functionality, testing various aspects of the IoT device to ensure it meets the required specifications. However, when moving to production, the emphasis shifts to scalability, cost-effectiveness, and reliability. This transition is not always seamless, as the prototype, designed for small-scale testing, might not be ready to meet the demands of large-scale manufacturing. For example, components used in prototypes might not be available in large quantities, or they might not meet the cost or durability requirements for mass production. Addressing these challenges early in the development process is essential to avoid delays and additional costs during the production phase.

Implementing Scalable Design for IoT Devices

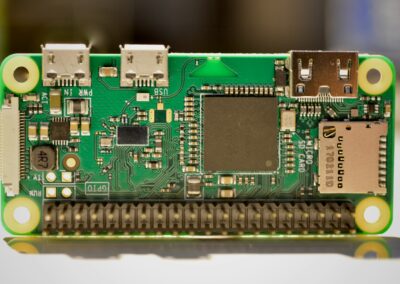

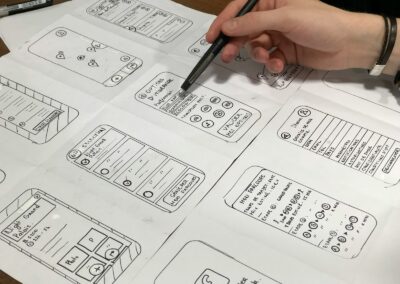

One of the most effective strategies for transitioning IoT prototyping to production involves implementing a scalable design from the outset. In markets such as Riyadh and Dubai, where innovation is rapidly advancing, designing IoT devices with scalability in mind can save significant time and resources. A scalable design ensures that the components used in the prototype can be easily adapted or replaced with alternatives that are suitable for mass production. This involves selecting components that are not only functional but also available in large quantities and at a reasonable cost. Additionally, modular design principles can be employed to allow for easier modifications as the project moves from prototyping to production. For example, using standardized components and interfaces can make it easier to scale up production and integrate new features without redesigning the entire system. This approach not only facilitates a smoother transition but also enhances the flexibility and adaptability of the IoT device in response to evolving market demands.

Partnering with Experienced Manufacturers

Another critical strategy for transitioning IoT prototyping to production is partnering with experienced manufacturers who understand the complexities of IoT development. In regions like the UAE and Saudi Arabia, where the demand for IoT solutions is growing, working with manufacturers who have a proven track record in producing IoT devices can provide a significant advantage. These manufacturers bring expertise in areas such as component sourcing, assembly processes, and quality control, all of which are vital for ensuring that the final product meets the required standards. They can also offer insights into optimizing the production process, identifying potential bottlenecks, and suggesting improvements that can reduce costs and improve efficiency. By collaborating closely with manufacturers from the early stages of development, IoT developers can ensure that their prototypes are designed with production in mind, minimizing the risk of encountering issues during the transition to full-scale manufacturing.

Optimizing the IoT Development Process for Production Success

Incorporating Feedback Loops into the Development Process

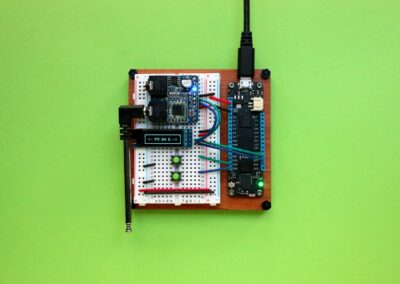

Incorporating feedback loops into the development process is a key strategy for transitioning IoT prototyping to production. This approach involves continuously gathering feedback from various stakeholders, including engineers, manufacturers, and end-users, throughout the development cycle. In markets like Saudi Arabia and Dubai, where technological advancements are rapidly being adopted, this iterative process allows developers to identify and address potential issues before they become significant problems during production. For example, feedback from manufacturers can highlight challenges related to component sourcing or assembly processes, allowing developers to make adjustments early on. Similarly, feedback from end-users can provide insights into the usability and functionality of the IoT device, ensuring that the final product meets customer expectations. By integrating feedback loops into the development process, IoT developers can create more robust prototypes that are better suited for mass production, ultimately leading to a smoother transition from prototype to product.

Leveraging Advanced Testing and Validation Techniques

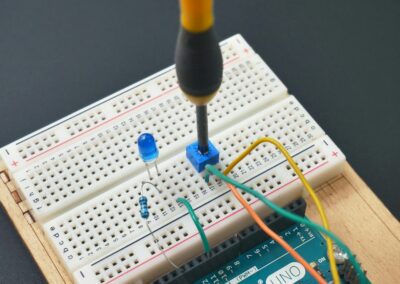

Advanced testing and validation techniques play a crucial role in ensuring that IoT prototypes are ready for production. Strategies for transitioning IoT prototyping to production must include rigorous testing to identify and resolve any issues that could affect the performance or reliability of the final product. In regions such as the UAE and Saudi Arabia, where the market demands high-quality IoT solutions, thorough testing is essential to maintain a competitive edge. This involves not only functional testing but also stress testing, environmental testing, and compliance testing to ensure that the IoT device can withstand the conditions it will encounter in real-world use. Advanced simulation tools can also be used to predict how the device will perform at scale, allowing developers to make necessary adjustments before moving to production. By prioritizing testing and validation, IoT developers can reduce the risk of costly recalls or product failures, ensuring a successful transition from prototyping to production.

Implementing Efficient Supply Chain Management

Efficient supply chain management is another critical factor in the successful transition of IoT prototyping to production. As IoT devices often rely on a wide range of components sourced from different suppliers, managing the supply chain effectively is essential to avoid delays and ensure that production schedules are met. In the fast-paced markets of Riyadh and Dubai, where demand for IoT solutions is high, supply chain disruptions can have significant consequences. To mitigate these risks, IoT developers should work closely with suppliers to ensure a reliable flow of components and materials. This includes establishing strong relationships with key suppliers, maintaining adequate inventory levels, and developing contingency plans to address potential disruptions. Additionally, using data analytics and IoT-enabled supply chain management tools can provide greater visibility and control over the supply chain, allowing for more proactive management of resources and ensuring that production runs smoothly. By implementing these strategies, IoT developers can streamline the transition from prototyping to production, reducing time-to-market and enhancing the overall success of their projects.

In conclusion, the successful transition from IoT prototyping to production requires careful planning, scalable design, strong partnerships, and efficient supply chain management. By implementing these strategies, IoT developers in regions like Saudi Arabia and the UAE can overcome the challenges associated with scaling up production and deliver high-quality products that meet market demands. As the IoT landscape continues to evolve, staying ahead of these challenges will be key to maintaining a competitive edge and driving innovation in the industry.

—

#IoTDevelopment #IoTPrototyping #SmartManufacturing #UAEIoT #SaudiArabiaTech #IoTProduction #IoTSupplyChain #IoTSolutions #InnovativeTechnology