Advancing Sustainable Manufacturing: 3D Printing with Recycled Materials

The Role of 3D Printing in Sustainable Manufacturing

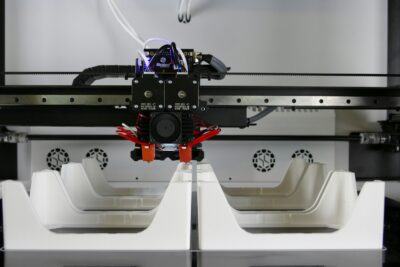

One of the key strategies in achieving sustainability in manufacturing processes is the utilization of recycled materials. 3D printing, also known as additive manufacturing, excels in this aspect by enabling the fabrication of complex parts and products using recycled plastics, metals, and other eco-friendly materials. The adoption of 3D printing technology is revolutionizing the landscape of sustainable manufacturing by offering innovative solutions that reduce waste and promote environmental conservation.

In Saudi Arabia and the UAE, where there is a growing emphasis on environmental responsibility and sustainable development, the integration of 3D printing with recycled materials holds immense potential. Riyadh and Dubai are at the forefront of this movement, with companies and research institutions investing in cutting-edge technologies to address pressing environmental challenges. By harnessing the power of 3D printing, these regions can reduce their reliance on traditional manufacturing methods that often result in high levels of waste and pollution.

The versatility of 3D printing allows for the creation of intricate designs that optimize material usage and minimize scrap. Unlike subtractive manufacturing processes, which generate substantial waste from machining and cutting, additive manufacturing builds objects layer by layer, resulting in significantly lower material wastage. This inherent efficiency makes 3D printing an attractive option for sustainable manufacturing initiatives, offering a more environmentally friendly alternative to conventional production methods.

Driving Eco-Friendly Innovation with 3D Printing

In addition to utilizing recycled materials, 3D printing offers numerous other benefits that contribute to sustainable manufacturing practices. One such advantage is the ability to produce on-demand and localized manufacturing, reducing the need for long-distance transportation and minimizing carbon emissions. This is particularly relevant in regions like Saudi Arabia and the UAE, where importing goods from distant locations can have significant environmental impacts.

Furthermore, 3D printing enables the creation of lightweight and optimized designs that result in more energy-efficient products. By utilizing advanced design software and generative algorithms, manufacturers can optimize the structural integrity of components while minimizing material usage. This not only reduces the environmental footprint of products but also lowers production costs and enhances overall resource efficiency.

Moreover, 3D printing facilitates the implementation of circular economy principles by enabling the recycling and reprocessing of end-of-life products and manufacturing waste. Additive manufacturing systems can integrate recycled materials into new production cycles, closing the loop and reducing the reliance on virgin resources. This closed-loop approach aligns with the sustainability goals of Saudi Arabia and the UAE, promoting a circular economy model that maximizes resource utilization and minimizes waste generation.

The Future of Sustainable Manufacturing

As the demand for sustainable solutions continues to grow, the role of 3D printing in manufacturing will become increasingly prominent. In Riyadh, Dubai, and beyond, businesses and policymakers are recognizing the potential of additive manufacturing technologies to drive eco-friendly innovation and support the transition to a circular economy. By investing in research and development initiatives and fostering collaboration between industry stakeholders, these regions can accelerate the adoption of sustainable manufacturing practices and lead the way towards a more environmentally conscious future.

In conclusion, sustainable 3D printing with recycled materials represents a paradigm shift in manufacturing, offering a viable pathway towards environmental stewardship and resource conservation. Through strategic investments in technology and infrastructure, Saudi Arabia and the UAE can leverage the power of 3D printing to create a more sustainable and resilient industrial ecosystem. By embracing eco-friendly innovation, these regions can position themselves as global leaders in sustainable manufacturing and contribute to the creation of a greener and more prosperous future for generations to come.

Conclusion

The integration of 3D printing with recycled materials marks a significant milestone in the journey towards sustainable manufacturing. By leveraging additive manufacturing technologies, businesses can reduce waste, minimize environmental impact, and drive innovation in the production of goods. As Saudi Arabia and the UAE embrace these advancements, they pave the way for a more sustainable and prosperous future, where economic growth is harmonized with environmental conservation.

Looking Ahead

As we look to the future, the continued advancement of sustainable manufacturing practices will be essential for addressing global environmental challenges. Through collaborative efforts and technological innovation, we can build a more resilient and environmentally conscious society. By harnessing the potential of 3D printing and recycled materials, we can create a world where sustainability is not just a goal but a reality.

—

#3DPrinting #SustainableManufacturing #RecycledMaterials #EcoFriendlyTechnology #SaudiArabiaInnovation #UAEEnvironmentalInitiatives #RiyadhSustainability #DubaiGreenTechnology