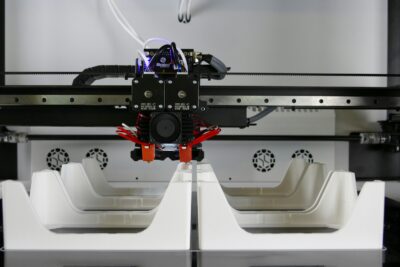

Advancing Production with Additive Manufacturing

Revolutionizing Production Processes

With the ability to create intricate designs and complex geometries, 3D printing is transforming the way functional end-use parts are produced. In Saudi Arabia and the UAE, where manufacturing is a cornerstone of the economy, additive manufacturing is being embraced by industries ranging from aerospace and automotive to healthcare and consumer goods. The versatility and precision of 3D printing technology enable manufacturers to produce parts with unparalleled complexity and functionality, driving advancements in product performance and design.

Optimizing Supply Chains

One of the key advantages of additive manufacturing in producing functional end-use parts is its impact on supply chain optimization. Traditional manufacturing methods often involve lengthy lead times and high tooling costs, making it challenging for manufacturers to respond quickly to changing market demands. However, with additive manufacturing, companies can produce parts on-demand and in small batches, reducing inventory costs and minimizing the risk of overstocking or obsolescence. This agility allows manufacturers in Riyadh and Dubai to streamline their supply chains, improve inventory management, and accelerate time-to-market for new products, gaining a competitive edge in today’s fast-paced business environment.

Enhancing Product Performance

Additive manufacturing offers unparalleled freedom in design, enabling engineers to optimize parts for performance, durability, and functionality. By leveraging advanced materials and design techniques, manufacturers can create parts that are lighter, stronger, and more resilient than those produced using traditional methods. In sectors such as aerospace and automotive, where performance and reliability are paramount, additive manufacturing is revolutionizing the way components are designed and manufactured. In Saudi Arabia and the UAE, where innovation is driving economic growth, additive manufacturing is empowering manufacturers to push the boundaries of what’s possible, leading to breakthroughs in product performance and efficiency.

—

Innovating for the Future

Embracing Digital Transformation

As industries across Saudi Arabia and the UAE embrace digital transformation, additive manufacturing is poised to play a central role in shaping the future of production. By leveraging technologies such as Artificial Intelligence and Blockchain, manufacturers can optimize every stage of the additive manufacturing process, from design and simulation to production and quality control. The integration of AI algorithms and machine learning enables predictive maintenance and process optimization, ensuring consistent quality and reliability in part production. Blockchain technology offers transparency and traceability, enabling secure digital transactions and supply chain management, further enhancing the efficiency and resilience of additive manufacturing ecosystems.

Unlocking the Potential of The Metaverse

Looking ahead, the emergence of The Metaverse presents new opportunities for additive manufacturing and the production of functional end-use parts. As virtual and physical worlds converge, manufacturers can leverage virtual prototyping and simulation tools to accelerate product development and testing. The ability to visualize and interact with digital prototypes in immersive virtual environments enhances collaboration and innovation, enabling manufacturers to iterate rapidly and bring products to market faster. In Riyadh and Dubai, where technology is driving economic diversification, the adoption of additive manufacturing and virtual prototyping is paving the way for a future where production is agile, efficient, and sustainable.

—

#AdditiveManufacturing #FunctionalEndUseParts #3DPrinting #Manufacturing #SupplyChain #Innovation #DigitalTransformation #ArtificialIntelligence #Blockchain #TheMetaverse #Riyadh #Dubai #SaudiArabia #UAE